Search Results (Searched for: )

- Smitherman

- Smitherman

16 Jul 2025 12:57

Replied by Smitherman on topic Umbau der Steuerung auf LinuxCNC + EtherCAT

Umbau der Steuerung auf LinuxCNC + EtherCAT

Category: Deutsch

- Cerezas

- Cerezas

16 Jul 2025 12:00

Replied by Cerezas on topic Using a 7i92t as replacement for a parallel port

Using a 7i92t as replacement for a parallel port

Category: Driver Boards

- ziggi

16 Jul 2025 10:41 - 16 Jul 2025 10:42

Replied by ziggi on topic Troubles to get started with SD240 Retrofit

Troubles to get started with SD240 Retrofit

Category: Turning

- meister

- meister

16 Jul 2025 10:26

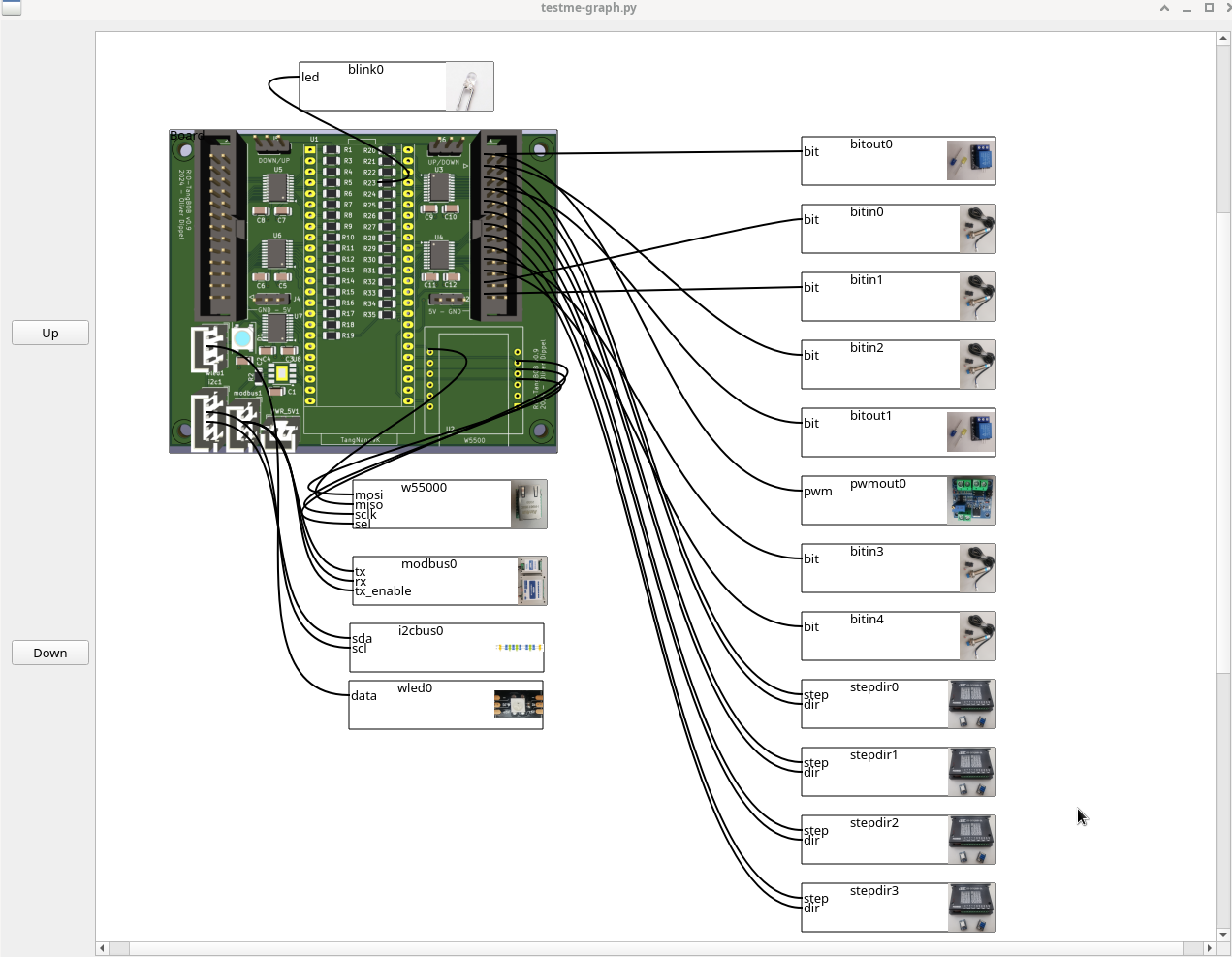

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- tommylight

16 Jul 2025 08:46 - 16 Jul 2025 08:48

Replied by tommylight on topic Mesa Auswahl für größeres Projekt

Mesa Auswahl für größeres Projekt

Category: Deutsch

- Hakan

- Hakan

16 Jul 2025 07:49

Replied by Hakan on topic PID tuning when you have a tuned Servo in CSP mode?

PID tuning when you have a tuned Servo in CSP mode?

Category: EtherCAT

- Hakan

- Hakan

16 Jul 2025 07:38

Replied by Hakan on topic PID tuning when you have a tuned Servo in CSP mode?

PID tuning when you have a tuned Servo in CSP mode?

Category: EtherCAT

- Hakan

- Hakan

16 Jul 2025 07:29

Replied by Hakan on topic How to use Fixed PDO mapping on Lichuan LC Servo

How to use Fixed PDO mapping on Lichuan LC Servo

Category: EtherCAT

- G0G53Z148

16 Jul 2025 06:53

Replied by G0G53Z148 on topic Mesa Auswahl für größeres Projekt

Mesa Auswahl für größeres Projekt

Category: Deutsch

- SebastianM

- SebastianM

16 Jul 2025 03:58

Replied by SebastianM on topic ATC Tool Rack implementation gesucht

ATC Tool Rack implementation gesucht

Category: Deutsch

- GeramyL

- GeramyL

16 Jul 2025 01:56

- Lcvette

16 Jul 2025 01:11 - 16 Jul 2025 01:12

Replied by Lcvette on topic probe basic ,manual tool change and tool setter question

probe basic ,manual tool change and tool setter question

Category: QtPyVCP

- PCW

16 Jul 2025 01:00

- unknown

- unknown

16 Jul 2025 00:54

- unknown

- unknown

16 Jul 2025 00:46

Replied by unknown on topic Graphical glitches with Raspberry Pi 400 + LinuxCNC 2.9.4 (arm64)

Graphical glitches with Raspberry Pi 400 + LinuxCNC 2.9.4 (arm64)

Category: Installing LinuxCNC

Time to create page: 0.245 seconds