Search Results (Searched for: )

- kworm

- kworm

30 Nov 2024 17:14

Replied by kworm on topic Leadshine EL8 Servo Drives - EtherCAT

Leadshine EL8 Servo Drives - EtherCAT

Category: Advanced Configuration

- kworm

- kworm

30 Nov 2024 17:03 - 30 Nov 2024 19:51

Replied by kworm on topic Ethercat auto configurator.

Ethercat auto configurator.

Category: EtherCAT

- lblabr

- lblabr

30 Nov 2024 17:01

Replied by lblabr on topic Raspberrypi 5 linuxcnc Image' screen resolution and color depth

Raspberrypi 5 linuxcnc Image' screen resolution and color depth

Category: General LinuxCNC Questions

- tommylight

30 Nov 2024 16:36

Replied by tommylight on topic Building a chain driven Plasma table.

Building a chain driven Plasma table.

Category: General LinuxCNC Questions

- tommylight

30 Nov 2024 16:29

Replied by tommylight on topic Black Friday Deal got me :)

Black Friday Deal got me :)

Category: Plasma & Laser

- tommy

- tommy

30 Nov 2024 16:29

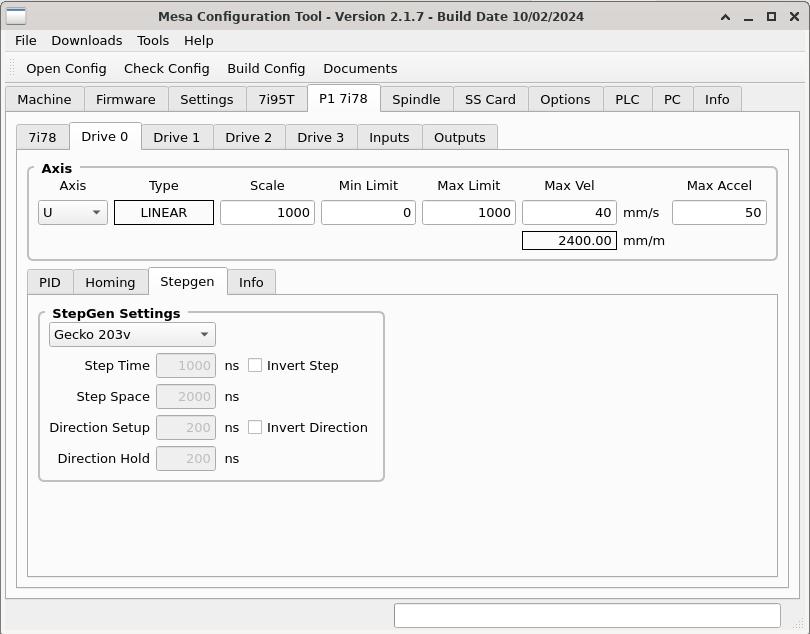

Replied by tommy on topic Mesa Configuration Tool

Mesa Configuration Tool

Category: Configuration Tools

- tommylight

30 Nov 2024 16:29

- PCW

30 Nov 2024 15:28 - 30 Nov 2024 15:29

- bkt

30 Nov 2024 15:18

Replied by bkt on topic Linuxcnc show linuxcnc-error window when close my gui app

Linuxcnc show linuxcnc-error window when close my gui app

Category: Advanced Configuration

- Axolito

30 Nov 2024 15:05

Replied by Axolito on topic Embed tab not displayed with autostart

Embed tab not displayed with autostart

Category: Gmoccapy

- RDA

- RDA

30 Nov 2024 15:01

- slowpoke

- slowpoke

30 Nov 2024 14:54

Replied by slowpoke on topic Small touchscreen display 7-10' -> 14-16"

Small touchscreen display 7-10' -> 14-16"

Category: General LinuxCNC Questions

- RDA

- RDA

30 Nov 2024 14:28

- Mecanix

- Mecanix

30 Nov 2024 14:06

- NTULINUX

30 Nov 2024 13:40 - 02 Dec 2024 13:24

Replied by NTULINUX on topic Gentoo Image, Which Applications are in and Which are Out

Gentoo Image, Which Applications are in and Which are Out

Category: General LinuxCNC Questions

Time to create page: 0.444 seconds