Building a chain driven Plasma table.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

29 Nov 2024 21:41 #315588

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

So now I need to figure out the hardware side. I do have a dividing table with a chuck on it. Unfortunately it seems the gearing is not suitable 1:90 4 degrees per turn.

so I guess I will be better off removing tha chuck and make a way to fit it on a shaft with bearings. The cam belt gears have a ratio of 1:4 which seems a bit small to me.

will it work with a 100mm chuck and pipes up to 150mm

so I guess I will be better off removing tha chuck and make a way to fit it on a shaft with bearings. The cam belt gears have a ratio of 1:4 which seems a bit small to me.

will it work with a 100mm chuck and pipes up to 150mm

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

30 Nov 2024 07:51 #315614

by tommylight

Replied by tommylight on topic Building a chain driven Plasma table.

150*3.1415=471.225mm of surface times material thickness times 7850kg/m3

That gives you the weight, and at 6 meter length, even 1mm thick walls would be 22KG!

At 4mm, that is 88Kg, that have to be turned plus the friction and the chuck weight.

You can make it work with 1:4 reduction, but it would have to be at miserably low acceleration.

Do you have a 3D printer? Print some pulleys, find a HTD5 belt, at least 15mm wide, use a lot of walls to enforce the mount holes on pulleys.

That gives you the weight, and at 6 meter length, even 1mm thick walls would be 22KG!

At 4mm, that is 88Kg, that have to be turned plus the friction and the chuck weight.

You can make it work with 1:4 reduction, but it would have to be at miserably low acceleration.

Do you have a 3D printer? Print some pulleys, find a HTD5 belt, at least 15mm wide, use a lot of walls to enforce the mount holes on pulleys.

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

30 Nov 2024 13:12 #315649

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

I think I will go max to 3 meter

I don’t have a 3D printer.

I could put some pulleys in series to get a better gear ratio.

What ratio would you recommend?

I don’t have a 3D printer.

I could put some pulleys in series to get a better gear ratio.

What ratio would you recommend?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

30 Nov 2024 16:36 #315662

by tommylight

Replied by tommylight on topic Building a chain driven Plasma table.

Minimum would probably be 1:10 for a Nema 23 or 34 motor, should be usable up to 1:30.

I would reference from the other side of the equation, 2-3 meters per minute of cut feed rate for 40A to 60A plasma, so for 150mm tube that would make 4 turns per minute roughly, easily done, but for 50mm tube that would be roughly 15 turns per minute.

The good thing with steppers in this case is more torque at lower speed, so start form 3 to 5 turns per minute and see what you can get on a high side.

I would reference from the other side of the equation, 2-3 meters per minute of cut feed rate for 40A to 60A plasma, so for 150mm tube that would make 4 turns per minute roughly, easily done, but for 50mm tube that would be roughly 15 turns per minute.

The good thing with steppers in this case is more torque at lower speed, so start form 3 to 5 turns per minute and see what you can get on a high side.

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

12 Jan 2025 16:45 #318794

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

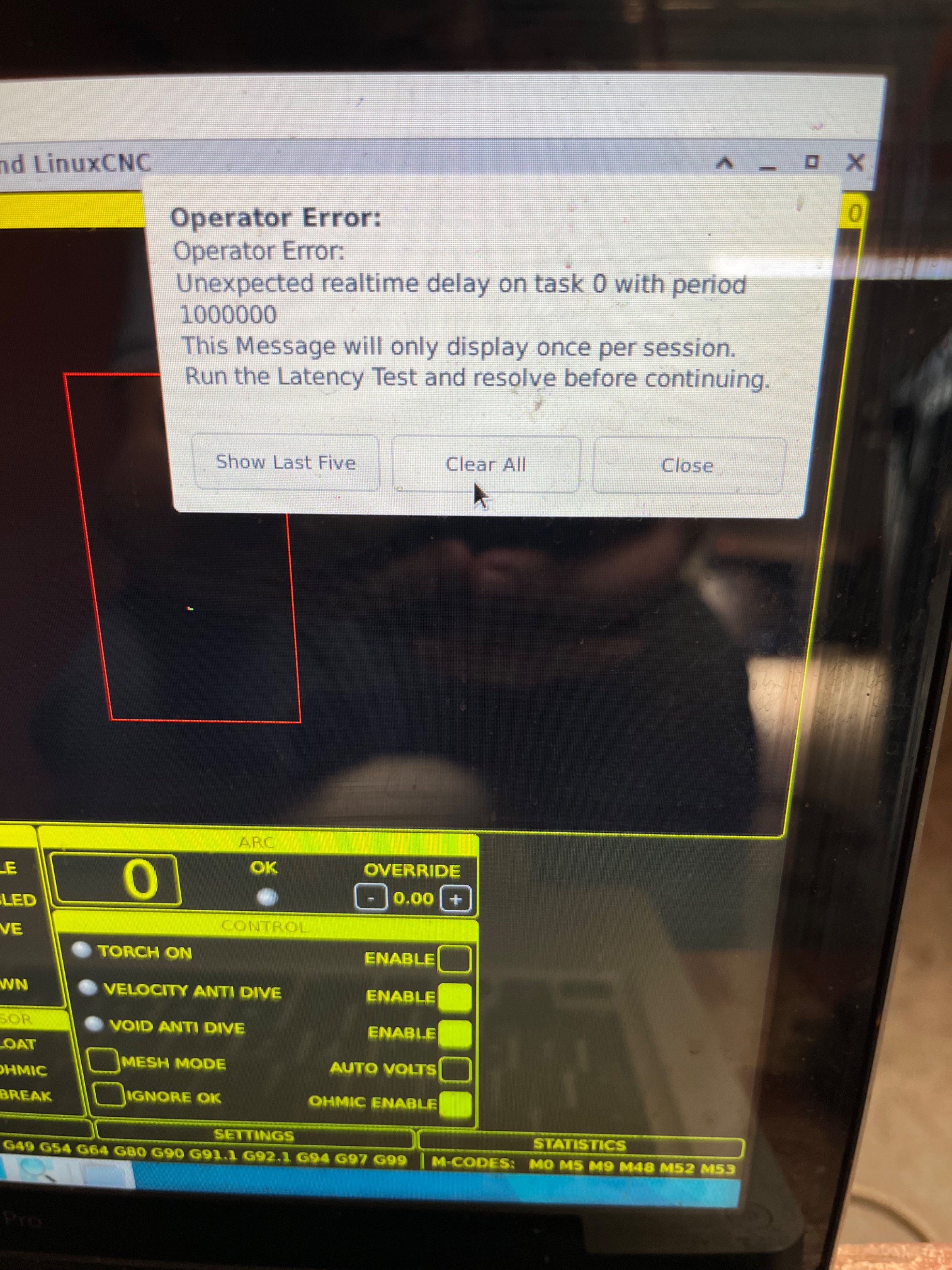

So I upgraded to linuxcnc 2.9 and the error message is back? What can cause this?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

12 Jan 2025 17:18 #318801

by tommylight

Replied by tommylight on topic Building a chain driven Plasma table.

What error?

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

12 Jan 2025 18:31 - 12 Jan 2025 18:35 #318809

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

Attachments:

Last edit: 12 Jan 2025 18:35 by Creative25.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17590

- Thank you received: 5145

12 Jan 2025 23:49 #318833

by PCW

Replied by PCW on topic Building a chain driven Plasma table.

You likely need to disable IRQ coalescing as described in the hm2_eth manual page

man hm2_eth

man hm2_eth

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

18 Jan 2025 14:05 #319278

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

I have been busy the last few days.

It looks like IRQ coalescing is disabled by default.

Just reinstalled ethtool.

No error message so far.

Just waiting to see if the error appears at random.

It looks like IRQ coalescing is disabled by default.

Just reinstalled ethtool.

No error message so far.

Just waiting to see if the error appears at random.

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

27 Jan 2025 11:22 #319943

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

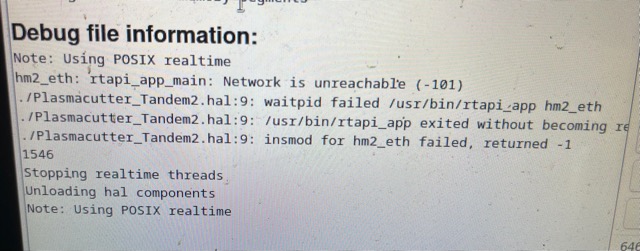

I tried to install tigervnc and it destroyed my system after logingb in with the correct password it just keeps taking me back to the login.So I reinstalled linuxcnc und updated it.now I can not connect to the mesa Ethernet card 7i76Ei get the following error.

Did I do something wrong during installation?

Did I do something wrong during installation?

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 1.680 seconds