Building a chain driven Plasma table.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

09 Sep 2024 12:28 #309739

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

At the moment I don’t have a Linux machine available. Only a MacBook M1.

But I will definitely try it when I get home. It looks like a promising project.

But I will definitely try it when I get home. It looks like a promising project.

The following user(s) said Thank You: meister

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

13 Sep 2024 23:56 #310109

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

I just tried viacomstructor.

It seems to generate Gcode that can run on a qtplasmac sim configuration.

However it looks like it does not generate lead ins that I selected under leads. Is there something I do wrong?

It seems to generate Gcode that can run on a qtplasmac sim configuration.

However it looks like it does not generate lead ins that I selected under leads. Is there something I do wrong?

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

14 Sep 2024 05:50 #310113

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

I just realized. I have to select the starting points manually then it adds the lead ins etc.

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

14 Sep 2024 09:43 #310133

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

So basically it looks like it does what I am looking for.

The biggest limitation is my lack of understanding all the functions of the software.

Are there any help files or tutorials for viaconstructor?

The biggest limitation is my lack of understanding all the functions of the software.

Are there any help files or tutorials for viaconstructor?

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

18 Sep 2024 06:32 - 18 Sep 2024 06:45 #310356

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

So far the building of the machine was all much easier than I expected.

But welding the water table is a big challenge.

Since I could not find a peace of sheet metal l large enough it is all warping up. And as it is now it is not usable. I would appreciate any advice on how to get those sheets straight again.

But welding the water table is a big challenge.

Since I could not find a peace of sheet metal l large enough it is all warping up. And as it is now it is not usable. I would appreciate any advice on how to get those sheets straight again.

Attachments:

Last edit: 18 Sep 2024 06:45 by Creative25.

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

21 Sep 2024 06:36 #310528

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

I must say viaconstructor works quite well for plasma. Only thing you have to do is choose laser cutter under machine and set the tool with.

I cut some complicated shapes like an Elephant.

However on one file a single shape I could not choose a starting point. Is there a bug with the software.

However I found an easy work around I just rotated the part and moved tho cut on a different part of the metal sheet.

I cut some complicated shapes like an Elephant.

However on one file a single shape I could not choose a starting point. Is there a bug with the software.

However I found an easy work around I just rotated the part and moved tho cut on a different part of the metal sheet.

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

21 Sep 2024 07:33 - 21 Sep 2024 07:35 #310530

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

I got the water tray into an acceptable condition.

I removed the problem welds and

welded some slats underneath to straighten things out. (The sheets had a radius when they came back from bending)

Then I re welded them..

Next time I would cut them in such a way that seems will be shorter and all in the same direction. I hope this post will help some others hobby welders avoid the same problems.

I removed the problem welds and

welded some slats underneath to straighten things out. (The sheets had a radius when they came back from bending)

Then I re welded them..

Next time I would cut them in such a way that seems will be shorter and all in the same direction. I hope this post will help some others hobby welders avoid the same problems.

Attachments:

Last edit: 21 Sep 2024 07:35 by Creative25.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

26 Sep 2024 19:15 - 26 Sep 2024 19:19 #310849

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

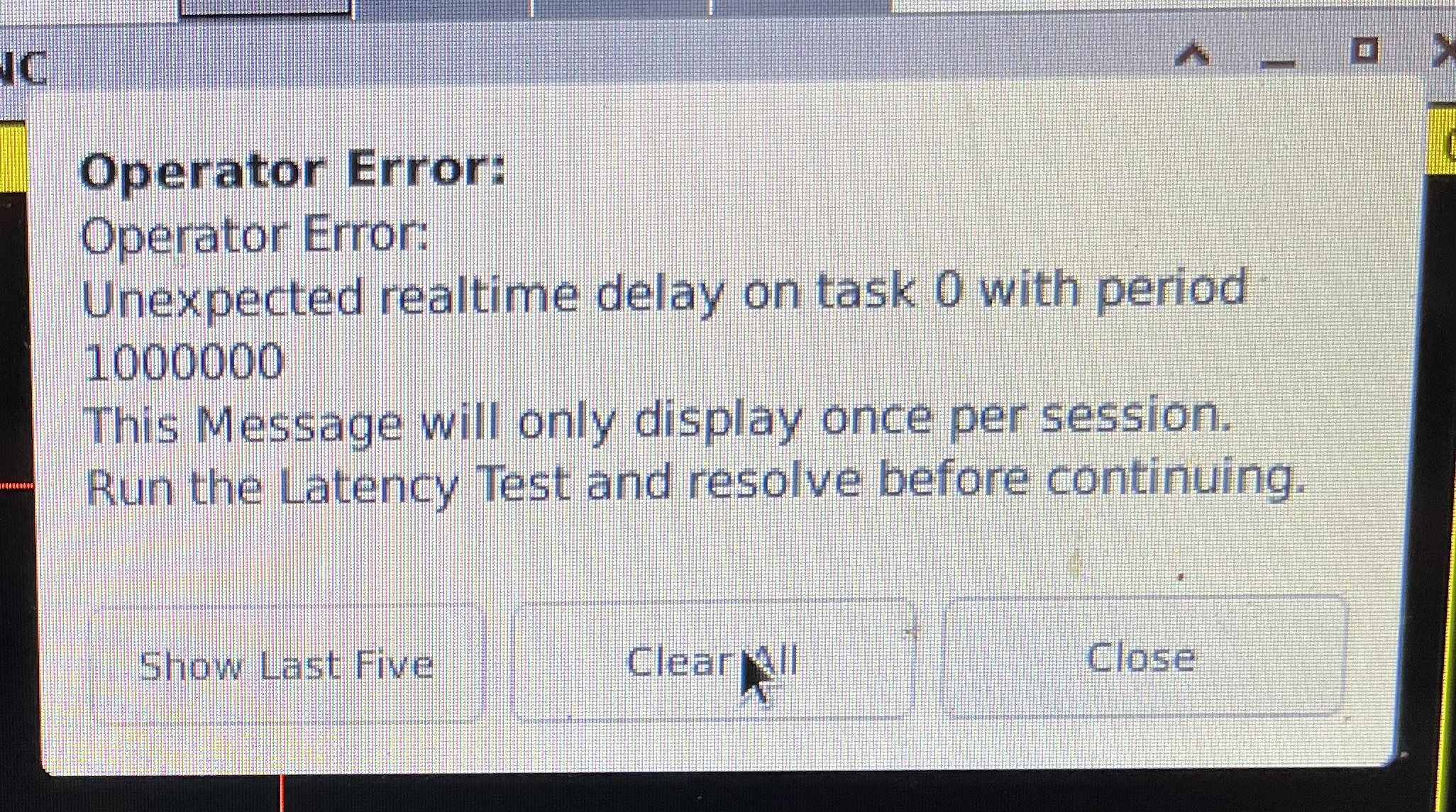

Attachments:

Last edit: 26 Sep 2024 19:19 by Creative25.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17625

- Thank you received: 5157

26 Sep 2024 20:57 #310855

by PCW

Replied by PCW on topic Building a chain driven Plasma table.

That means the host computer has a latency issue of some kind

Common causes:

Power management/speed-step/Turbo modes/C states >C1 enabled in BIOS

Network hardware issues with Ethernet connected cards

With Intel MACs you need to disable IRQ coalescing (man hm2_eth)

With Realtek MACs and the LinuxCNC buster release you may need to install

the DKMS RTK8168 driver as the driver included with the shipped kernel is broken

Common causes:

Power management/speed-step/Turbo modes/C states >C1 enabled in BIOS

Network hardware issues with Ethernet connected cards

With Intel MACs you need to disable IRQ coalescing (man hm2_eth)

With Realtek MACs and the LinuxCNC buster release you may need to install

the DKMS RTK8168 driver as the driver included with the shipped kernel is broken

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

27 Sep 2024 05:35 #310877

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

Thanks for the info.

Mine is an Intel MacBook 2012

Could you point me to some info on how to disable IRQ?

Mine is an Intel MacBook 2012

Could you point me to some info on how to disable IRQ?

Please Log in or Create an account to join the conversation.

Time to create page: 0.348 seconds