Building a chain driven Plasma table.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

21 Apr 2021 16:55 #206677

by Creative25

Building a chain driven Plasma table. was created by Creative25

I am starting this thread to share my build of a plasma table. My aim is a building a plasma table on a budget trying to use materials locally available as much as possible. Aim is to be able to cut metal sheets that are 1.2 x 2.4 meters. I will try to share the challenges And solutions.

Because I don’t have space for the table yet. I am starting with the Z axis and Y axis. Because I want to load things from

the side the gantry will be the X axis so the x axis will have 2 Stepper Motors.

Because I don’t have space for the table yet. I am starting with the Z axis and Y axis. Because I want to load things from

the side the gantry will be the X axis so the x axis will have 2 Stepper Motors.

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

21 Apr 2021 17:03 - 21 Apr 2021 17:04 #206678

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

I just had a rude surprise. The sprockets non precision surprises me. Both the shoulder and pilot hole of the sprocket are at least 1mm off center, compared to the teeth.

Question is that normal? What tolerances would you expect on sprockets?

Question is that normal? What tolerances would you expect on sprockets?

Last edit: 21 Apr 2021 17:04 by Creative25.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

21 Apr 2021 17:12 #206681

by Todd Zuercher

Replied by Todd Zuercher on topic Building a chain driven Plasma table.

Generally the words "chain" and "precision" don't belong in the same sentence.

The following user(s) said Thank You: Creative25

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

21 Apr 2021 17:35 #206685

by robertspark

Replied by robertspark on topic Building a chain driven Plasma table.

can I suggest that maybe you contact a guy called acourtjester on the plasma spider forum.

he has and does use chains a lot for plasma and has made quite a few plasma cutters, and can probably provide you with some good advice. he has a set of plans too which he has built on over the years. he is slowing dipping his toe in linuxcnc so he may pop up on here, buy you are best contacting him on the plasma spider forum.

not related to chain driven plasma, but you can find him via this thread

www.plasmaspider.com/viewtopic.php?f=55&t=32241#p196653

he has and does use chains a lot for plasma and has made quite a few plasma cutters, and can probably provide you with some good advice. he has a set of plans too which he has built on over the years. he is slowing dipping his toe in linuxcnc so he may pop up on here, buy you are best contacting him on the plasma spider forum.

not related to chain driven plasma, but you can find him via this thread

www.plasmaspider.com/viewtopic.php?f=55&t=32241#p196653

The following user(s) said Thank You: Creative25

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

21 Apr 2021 17:39 #206687

by robertspark

Replied by robertspark on topic Building a chain driven Plasma table.

here is one with images and chains.

trust me there are zero things wrong with his work and stuff he produces on his tables in steel and wood or even plastic logos with a drag knife..... if there were ANY issues they would show up.

www.plasmaspider.com/viewtopic.php?f=147...&hilit=chain#p191213

trust me there are zero things wrong with his work and stuff he produces on his tables in steel and wood or even plastic logos with a drag knife..... if there were ANY issues they would show up.

www.plasmaspider.com/viewtopic.php?f=147...&hilit=chain#p191213

The following user(s) said Thank You: Creative25

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

21 Apr 2021 17:44 #206688

by robertspark

Replied by robertspark on topic Building a chain driven Plasma table.

The following user(s) said Thank You: Creative25

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

21 Apr 2021 20:17 #206700

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

Unfortunately I don’t have access to the pictures.

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

21 Apr 2021 20:31 #206701

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

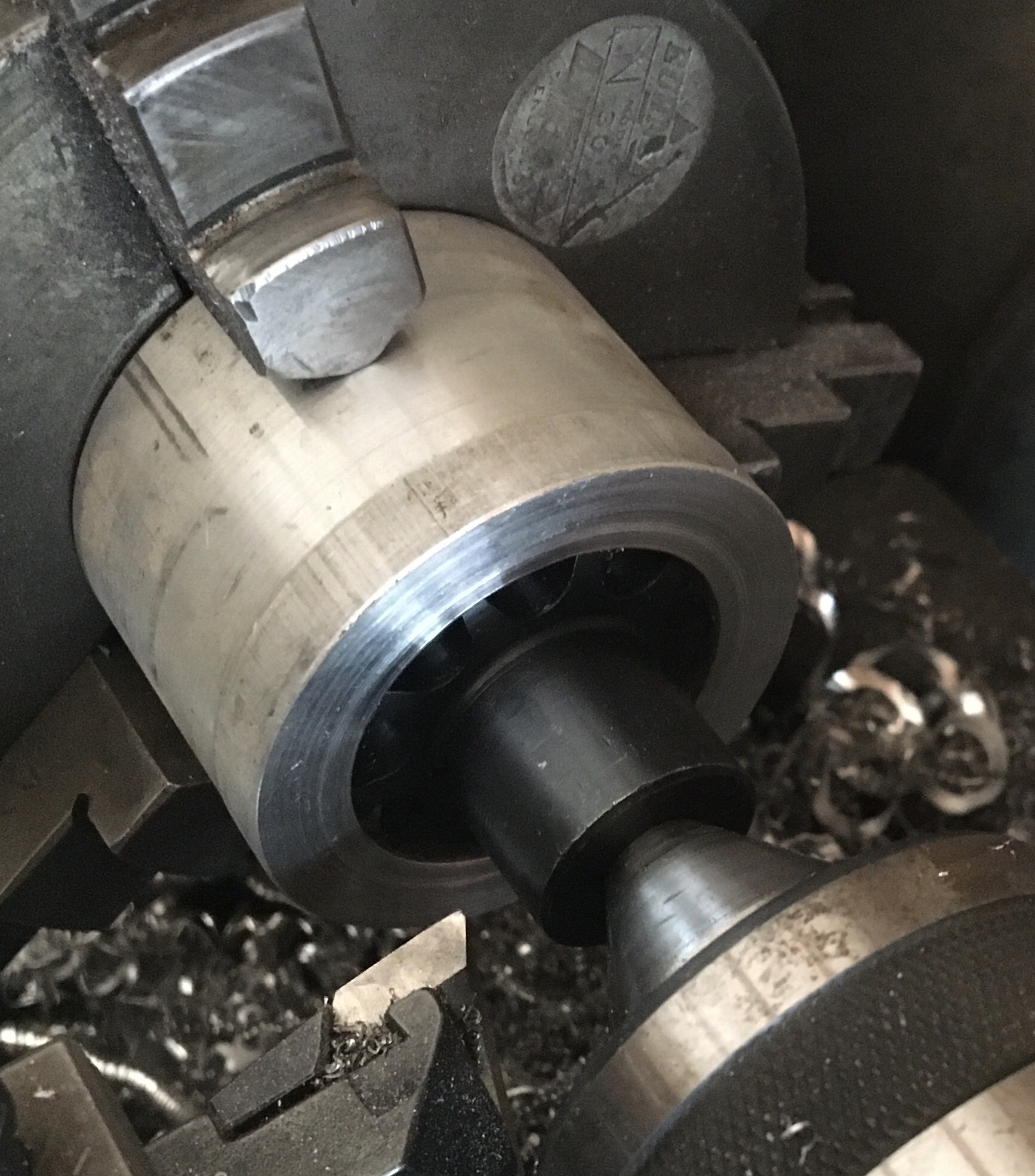

So from what I learn sprockets are not precise. So I made a plan. On the Lathe I drilled a hole that is slightly smaller than the diameter of the gear into a peace of aluminum. Turned the shoulder down till it was centered. After that I put the sprockets into the chuck and made the pilot hole bigger. Now they are within 0.1 mm I think that is acceptable.

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19807

- Thank you received: 4613

22 Apr 2021 00:20 #206745

by andypugh

I think that you should expect better than that. In fact you should send the parts back for a refund.

Sprockets should be perfectly concentric, they can't work properly otherwise.

If I was making a plasma machine it would be a core-xy bicycle chain machine. Probably.

Replied by andypugh on topic Building a chain driven Plasma table.

I just had a rude surprise. The sprockets non precision surprises me. Both the shoulder and pilot hole of the sprocket are at least 1mm off center, compared to the teeth.

I think that you should expect better than that. In fact you should send the parts back for a refund.

Sprockets should be perfectly concentric, they can't work properly otherwise.

If I was making a plasma machine it would be a core-xy bicycle chain machine. Probably.

Please Log in or Create an account to join the conversation.

- Creative25

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 11

22 Apr 2021 04:11 #206761

by Creative25

Replied by Creative25 on topic Building a chain driven Plasma table.

Yes you actually have to send them

Back. I bought them locally and they had to order them so I decided to rather fix them.

I also have some cam pulleys I got from AliExpress these are also one mm off. Have to fix them as well and make a bigger shaft. If I knew I would have ordered with a smaller bore.

Just saying what does it help to use linear bearings if your pulleys are off center.

What precision would you expect from cam pulleys?

Back. I bought them locally and they had to order them so I decided to rather fix them.

I also have some cam pulleys I got from AliExpress these are also one mm off. Have to fix them as well and make a bigger shaft. If I knew I would have ordered with a smaller bore.

Just saying what does it help to use linear bearings if your pulleys are off center.

What precision would you expect from cam pulleys?

Please Log in or Create an account to join the conversation.

Time to create page: 0.146 seconds