Search Results (Searched for: )

- tommylight

22 Nov 2024 20:37

- tommylight

22 Nov 2024 20:35

Replied by tommylight on topic Installing LinuxCnc on and SSD

Installing LinuxCnc on and SSD

Category: General LinuxCNC Questions

- Aldenflorio

22 Nov 2024 20:33

Replied by Aldenflorio on topic Installing LinuxCnc on and SSD

Installing LinuxCnc on and SSD

Category: General LinuxCNC Questions

- tommylight

22 Nov 2024 20:33

Replied by tommylight on topic LinuxCNC on Linux Mint Debian Edition 6

LinuxCNC on Linux Mint Debian Edition 6

Category: Installing LinuxCNC

- tommylight

22 Nov 2024 20:30

Replied by tommylight on topic Installing LinuxCnc on and SSD

Installing LinuxCnc on and SSD

Category: General LinuxCNC Questions

- natholego11

22 Nov 2024 20:29

- Stanislavz

- Stanislavz

22 Nov 2024 19:56

Replied by Stanislavz on topic LinuxCNC on Linux Mint Debian Edition 6

LinuxCNC on Linux Mint Debian Edition 6

Category: Installing LinuxCNC

- Aldenflorio

22 Nov 2024 19:45 - 22 Nov 2024 19:46

Replied by Aldenflorio on topic Installing LinuxCnc on and SSD

Installing LinuxCnc on and SSD

Category: General LinuxCNC Questions

- gardenweazel

22 Nov 2024 19:42

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- Aldenflorio

22 Nov 2024 19:36 - 22 Nov 2024 19:39

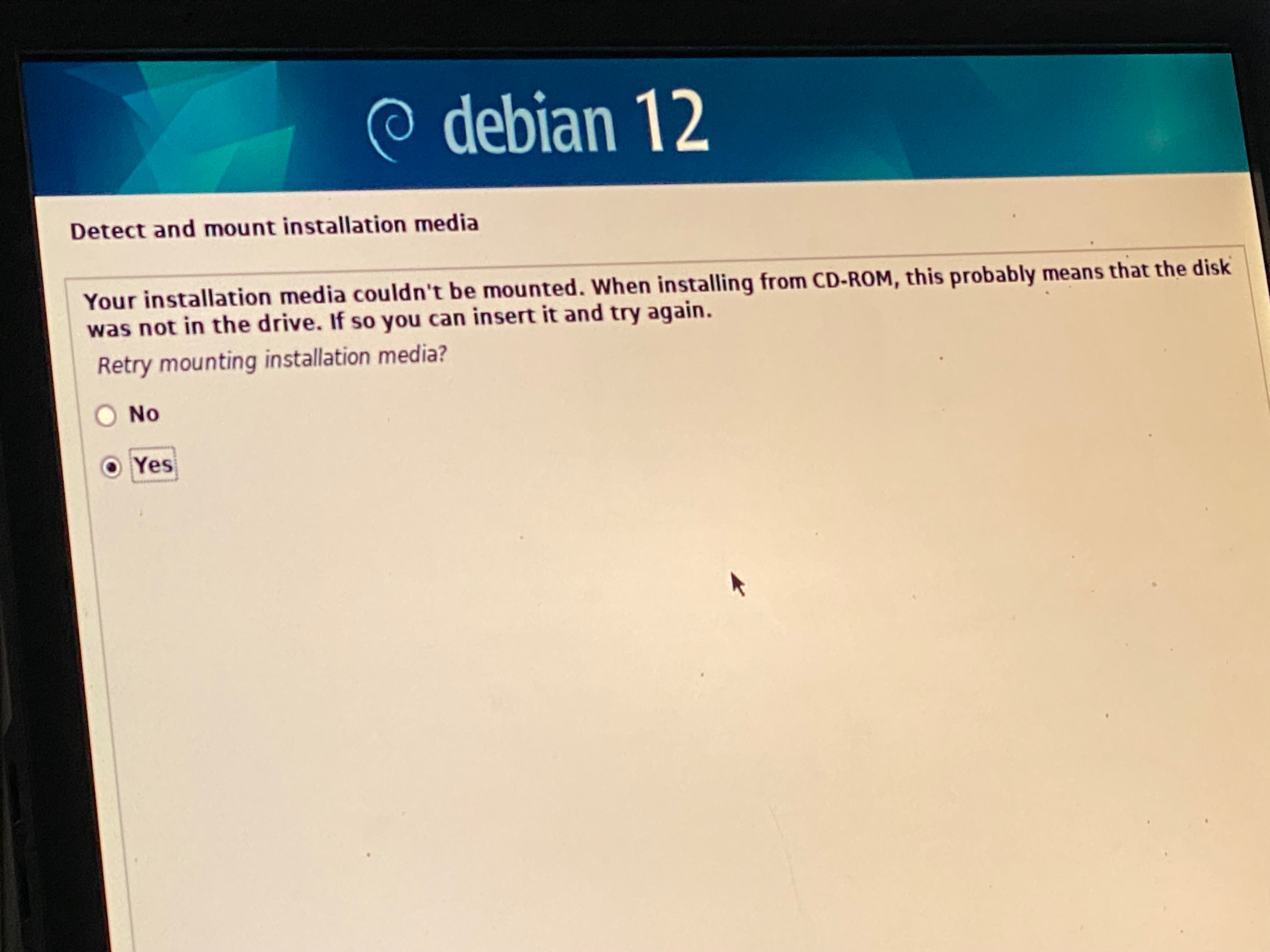

Installing LinuxCnc on and SSD was created by Aldenflorio

Installing LinuxCnc on and SSD

Category: General LinuxCNC Questions

- andypugh

22 Nov 2024 18:52 - 22 Nov 2024 18:52

Replied by andypugh on topic Best version for Parport machine and how to install

Best version for Parport machine and how to install

Category: Installing LinuxCNC

- tommylight

22 Nov 2024 18:26

Replied by tommylight on topic Latency on a Lenovo M715q

Latency on a Lenovo M715q

Category: General LinuxCNC Questions

- okielaxplyr

- okielaxplyr

22 Nov 2024 18:23 - 22 Nov 2024 18:24

Replied by okielaxplyr on topic Latency on a Lenovo M715q

Latency on a Lenovo M715q

Category: General LinuxCNC Questions

- tommylight

22 Nov 2024 18:22

Replied by tommylight on topic LinuxCNC on Linux Mint Debian Edition 6

LinuxCNC on Linux Mint Debian Edition 6

Category: Installing LinuxCNC

- PCW

22 Nov 2024 17:57 - 22 Nov 2024 18:12

Time to create page: 0.391 seconds