Search Results (Searched for: )

- Axolito

15 Nov 2024 22:11

Replied by Axolito on topic Flex GUI 1.0.2 released

Flex GUI 1.0.2 released

Category: Other User Interfaces

- Aciera

15 Nov 2024 22:02 - 15 Nov 2024 22:05

Replied by Aciera on topic Only one of the gantry joints move

Only one of the gantry joints move

Category: Basic Configuration

- tommylight

15 Nov 2024 21:45

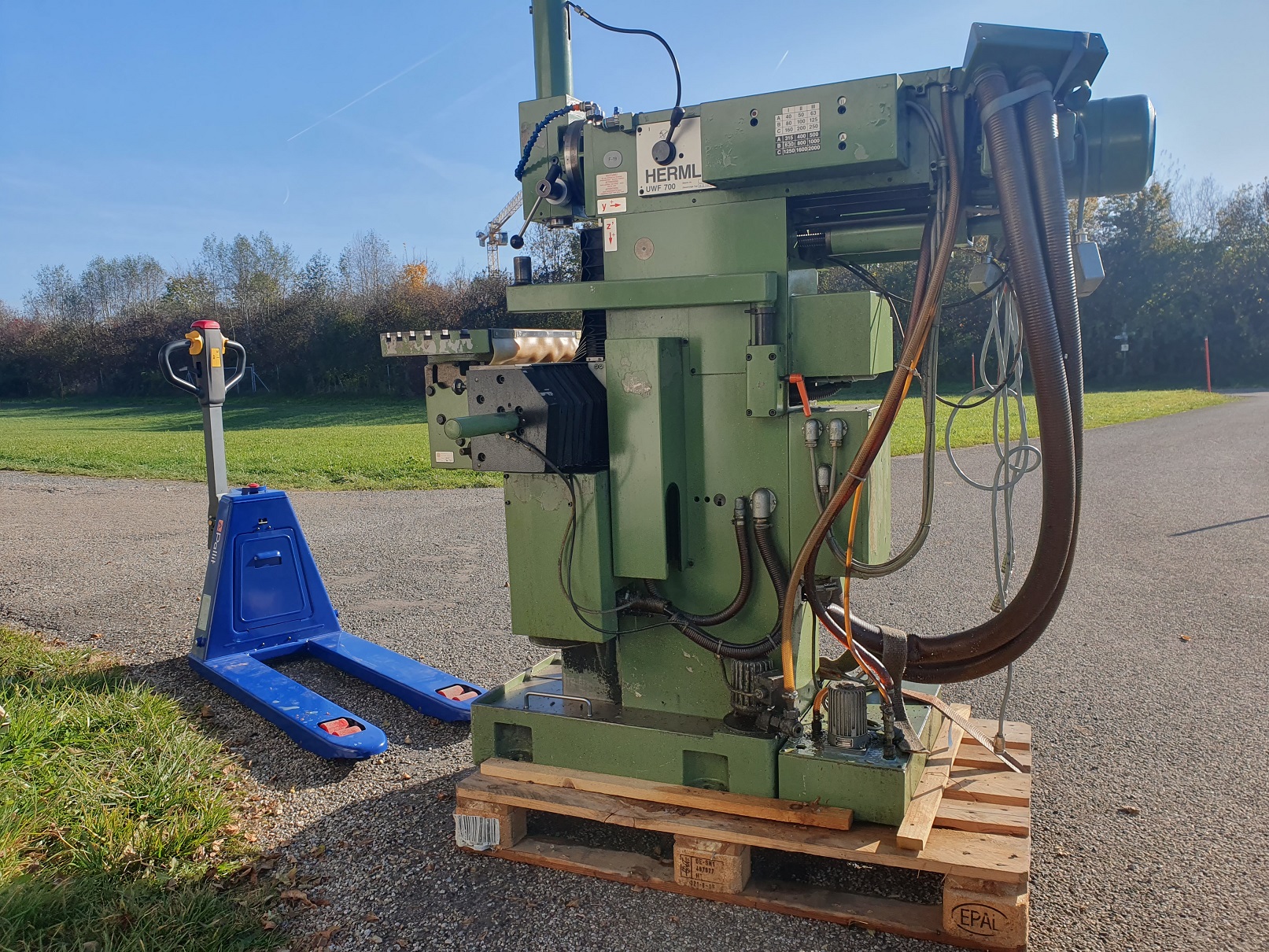

Replied by tommylight on topic Hermle UWF 700 Retrofit

Hermle UWF 700 Retrofit

Category: Milling Machines

- Dougal9887

- Dougal9887

15 Nov 2024 21:20

Replied by Dougal9887 on topic Error when trying to open Gmoccapy confiuration.

Error when trying to open Gmoccapy confiuration.

Category: Gmoccapy

- Mecanix

- Mecanix

15 Nov 2024 21:17 - 15 Nov 2024 21:43

Replied by Mecanix on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- Bassblaster

- Bassblaster

15 Nov 2024 20:59 - 15 Nov 2024 21:02

Hermle UWF 700 Retrofit was created by Bassblaster

Hermle UWF 700 Retrofit

Category: Milling Machines

- PCW

15 Nov 2024 20:57

Replied by PCW on topic solved: TB6 Inputs missing in MESA 7i95T

solved: TB6 Inputs missing in MESA 7i95T

Category: Driver Boards

- tommylight

15 Nov 2024 20:53

Replied by tommylight on topic Only one of the gantry joints move

Only one of the gantry joints move

Category: Basic Configuration

- tommylight

15 Nov 2024 20:52

Replied by tommylight on topic Error when trying to open Gmoccapy confiuration.

Error when trying to open Gmoccapy confiuration.

Category: Gmoccapy

- JanMrlth

15 Nov 2024 20:47

Replied by JanMrlth on topic solved: TB6 Inputs missing in MESA 7i95T

solved: TB6 Inputs missing in MESA 7i95T

Category: Driver Boards

- PCW

15 Nov 2024 20:38

Replied by PCW on topic Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Category: Driver Boards

- jkaminski

- jkaminski

15 Nov 2024 20:27 - 15 Nov 2024 20:30

Replied by jkaminski on topic Position vs Velocity mode

Position vs Velocity mode

Category: EtherCAT

- spumco

- spumco

15 Nov 2024 20:16

Replied by spumco on topic LinuxCNC for lathe questions

LinuxCNC for lathe questions

Category: General LinuxCNC Questions

- Malteser01

- Malteser01

15 Nov 2024 20:16

Replied by Malteser01 on topic Only one of the gantry joints move

Only one of the gantry joints move

Category: Basic Configuration

- Malteser01

- Malteser01

15 Nov 2024 20:12

Replied by Malteser01 on topic Only one of the gantry joints move

Only one of the gantry joints move

Category: Basic Configuration

Time to create page: 0.409 seconds