Search Results (Searched for: )

- Finngineering

- Finngineering

05 Nov 2024 18:05

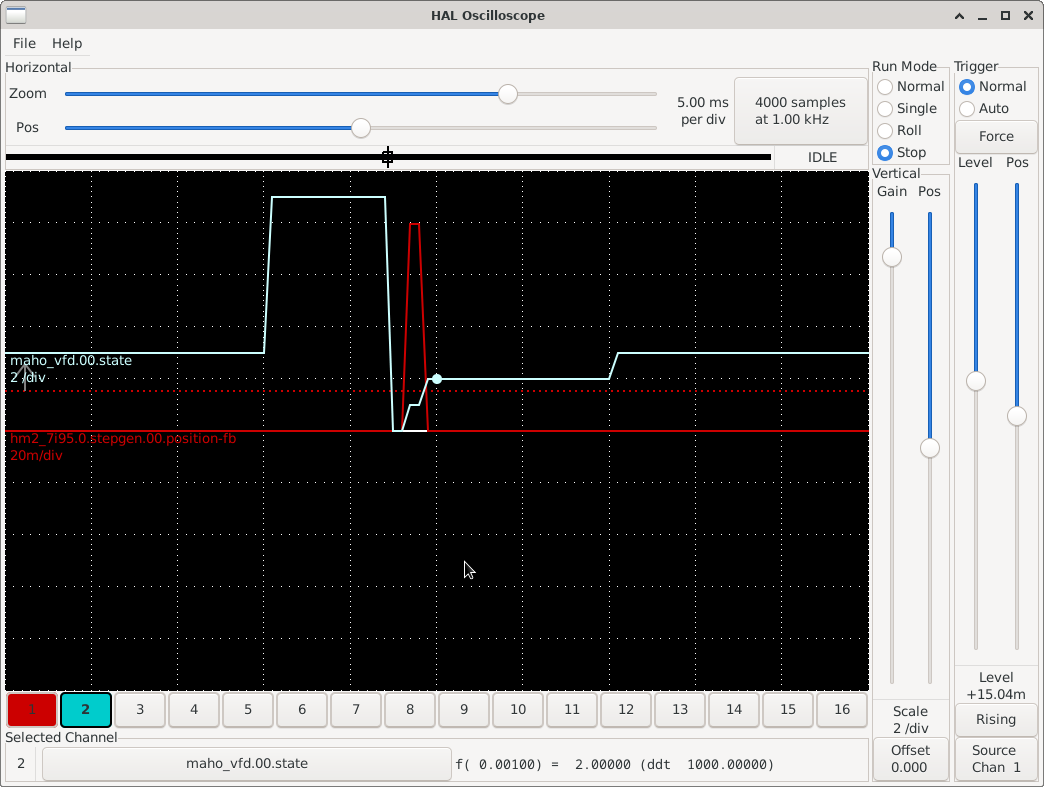

Replied by Finngineering on topic Strange stepgen behaviour with 7i95t_1pktv2d firmware

Strange stepgen behaviour with 7i95t_1pktv2d firmware

Category: Driver Boards

- digiex_chris

- digiex_chris

05 Nov 2024 17:59 - 05 Nov 2024 17:59

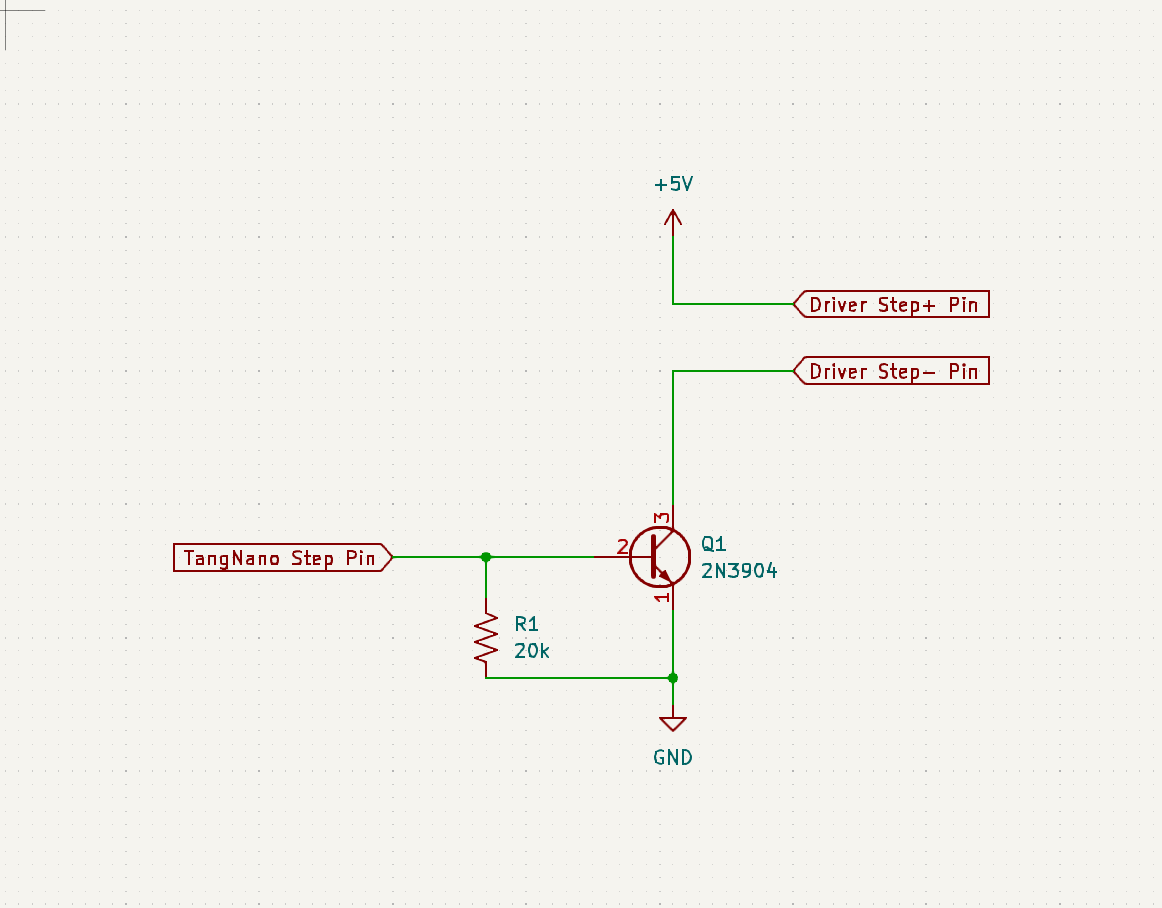

Replied by digiex_chris on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- tommylight

05 Nov 2024 17:07

Replied by tommylight on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- tommylight

05 Nov 2024 17:02

- endian

05 Nov 2024 16:59 - 06 Nov 2024 19:25

Replied by endian on topic Ethercat, EL6751 and CANOpen

Ethercat, EL6751 and CANOpen

Category: EtherCAT

- tommylight

05 Nov 2024 16:58

Replied by tommylight on topic Compensating For Angled Cut

Compensating For Angled Cut

Category: Plasma & Laser

- PCW

05 Nov 2024 16:50

Replied by PCW on topic Unexpected realtime delay on task 0 with period 1000000

Unexpected realtime delay on task 0 with period 1000000

Category: QtPyVCP

- CopperHead

- CopperHead

05 Nov 2024 16:47

- meister

- meister

05 Nov 2024 16:32

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- meister

- meister

05 Nov 2024 16:26

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- Micro2000

- Micro2000

05 Nov 2024 16:22 - 05 Nov 2024 16:23

- mBender

- mBender

05 Nov 2024 16:17

Replied by mBender on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- digiex_chris

- digiex_chris

05 Nov 2024 16:02 - 05 Nov 2024 16:03

Replied by digiex_chris on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- Lcvette

05 Nov 2024 15:30

Replied by Lcvette on topic Unexpected realtime delay on task 0 with period 1000000

Unexpected realtime delay on task 0 with period 1000000

Category: QtPyVCP

- digiex_chris

- digiex_chris

05 Nov 2024 15:26 - 05 Nov 2024 15:31

Replied by digiex_chris on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

Time to create page: 0.435 seconds