Search Results (Searched for: )

- andypugh

10 Sep 2024 12:10

Replied by andypugh on topic 3phase motor and pulley

3phase motor and pulley

Category: Advanced Configuration

- russkinch

10 Sep 2024 11:41

3phase motor and pulley was created by russkinch

3phase motor and pulley

Category: Advanced Configuration

- besriworld

- besriworld

10 Sep 2024 11:35

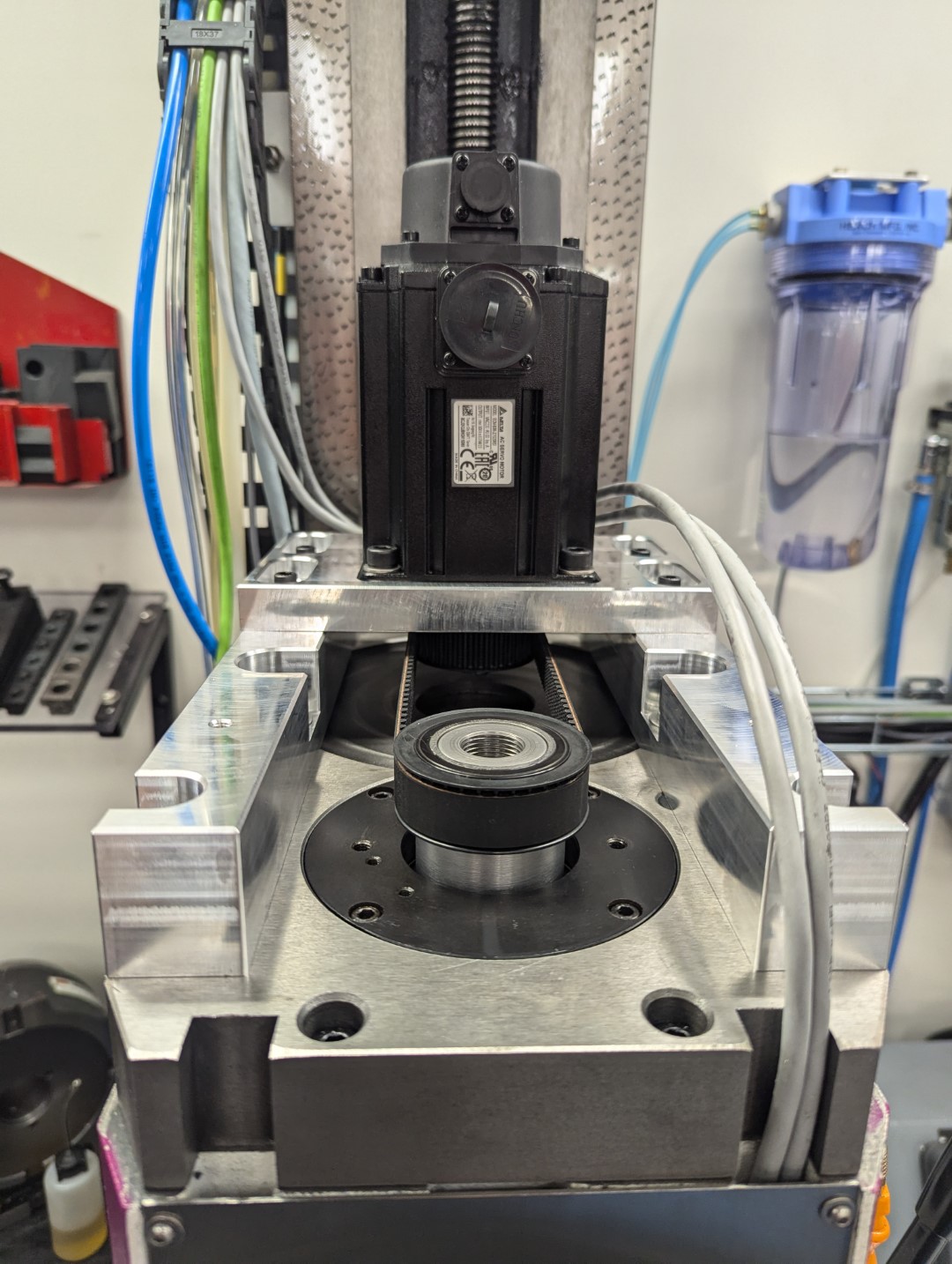

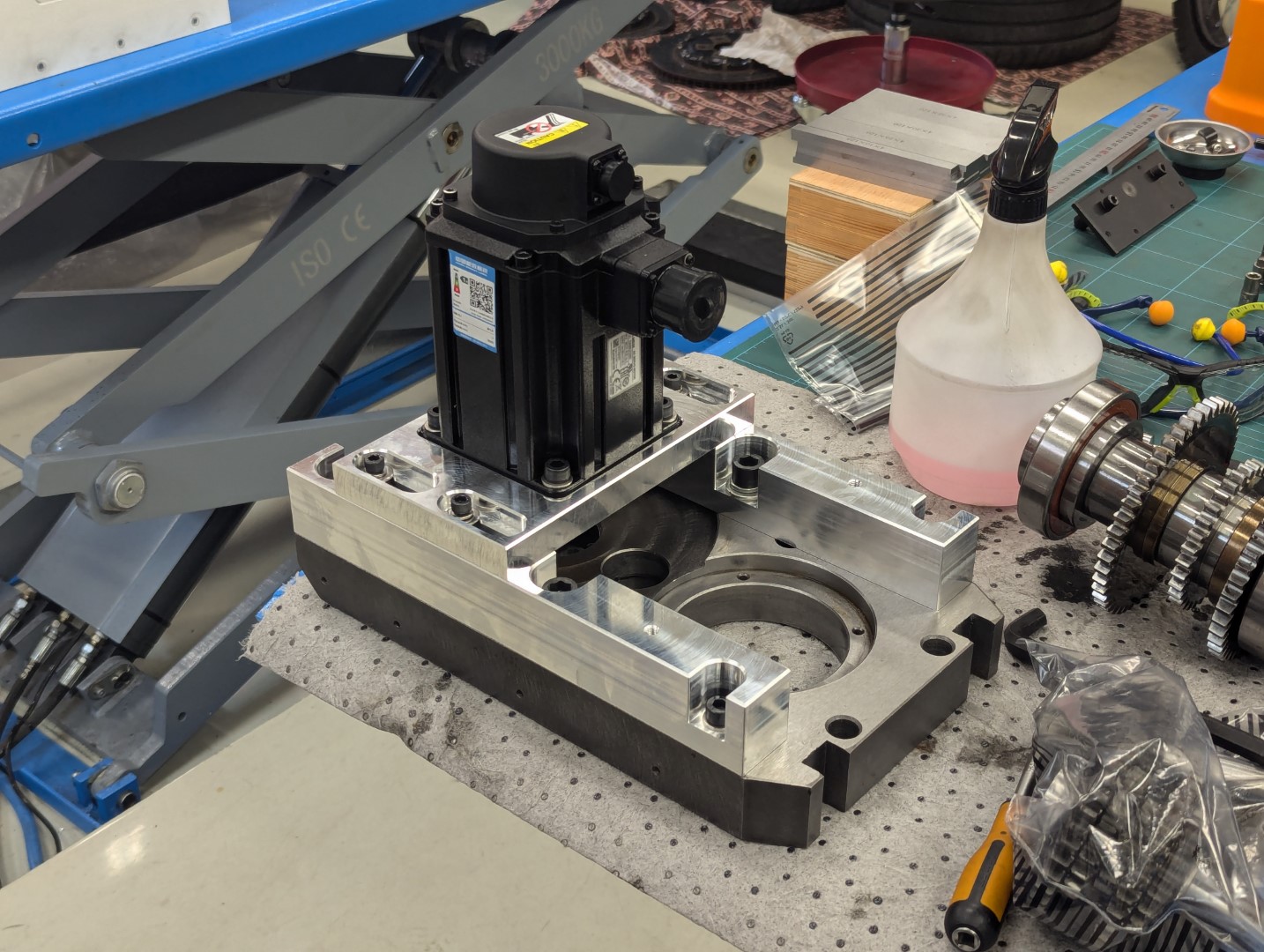

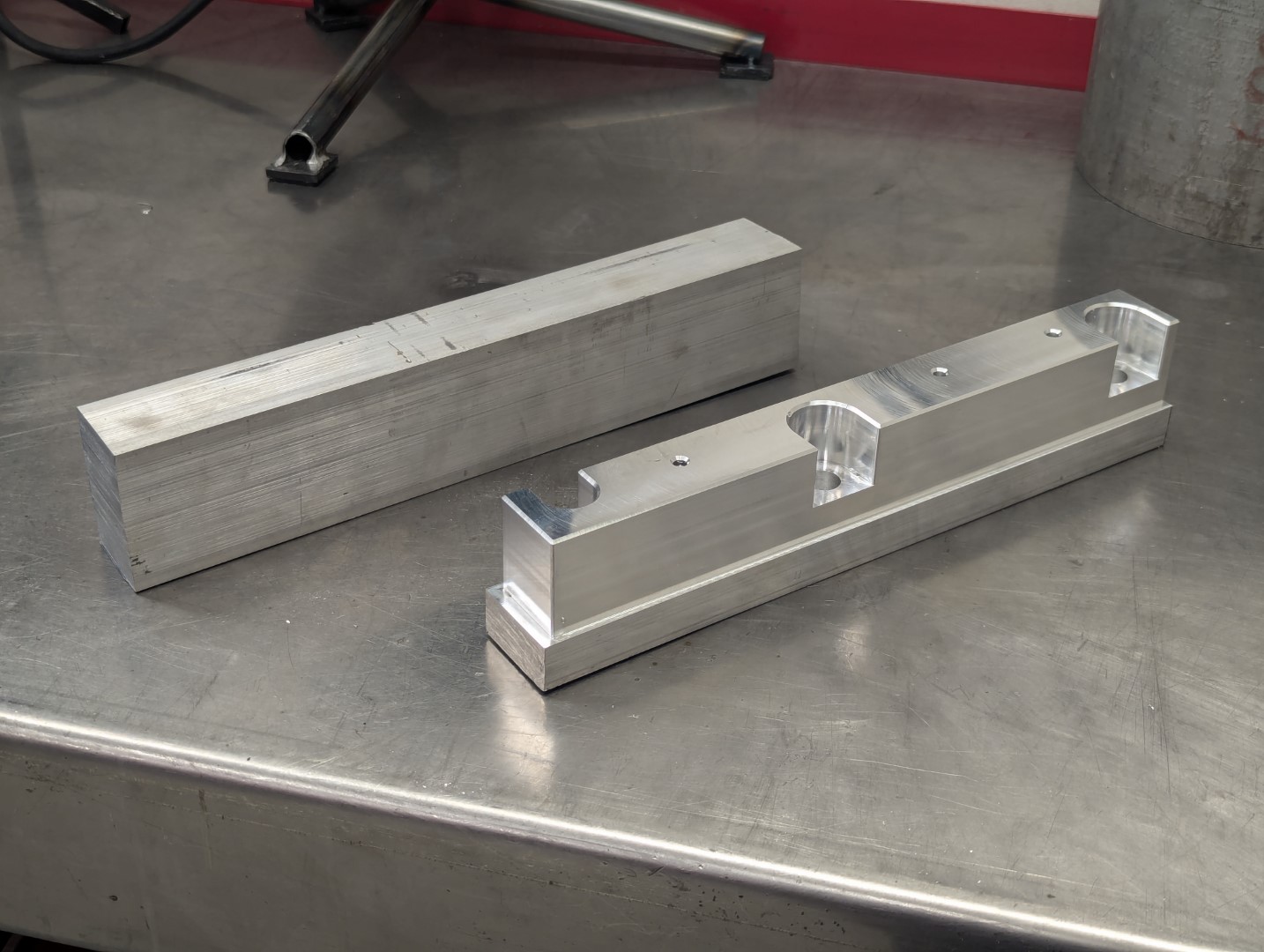

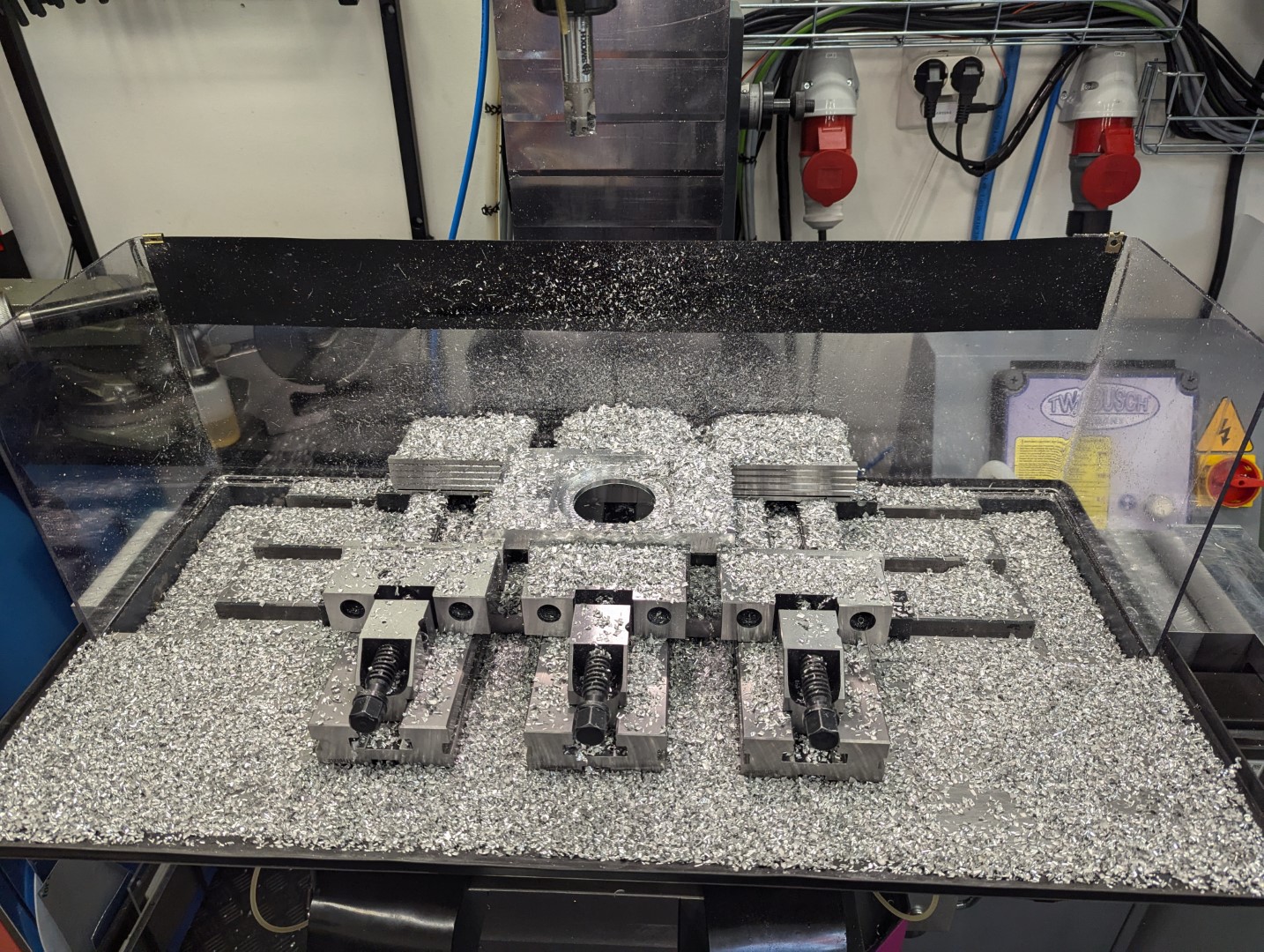

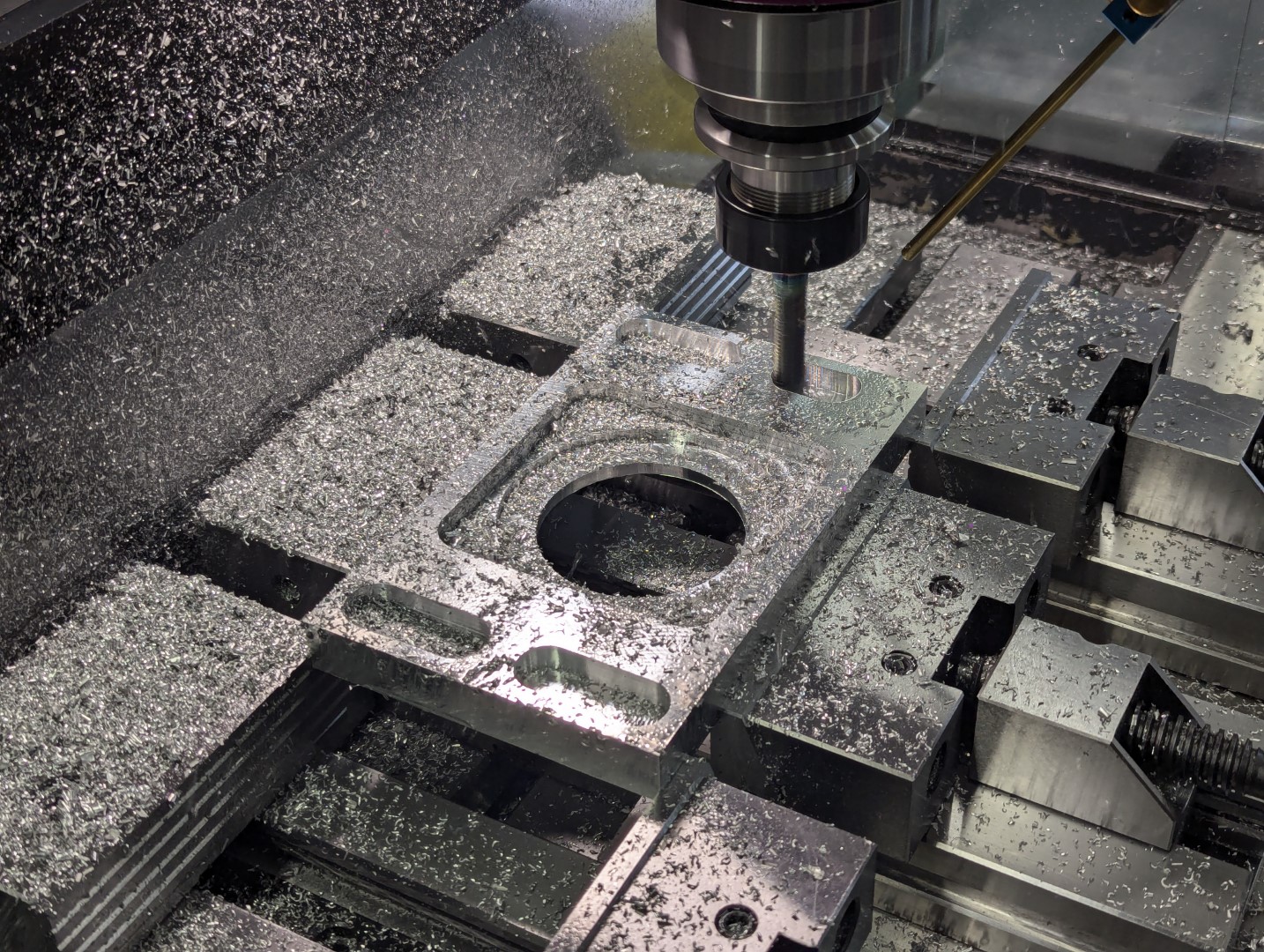

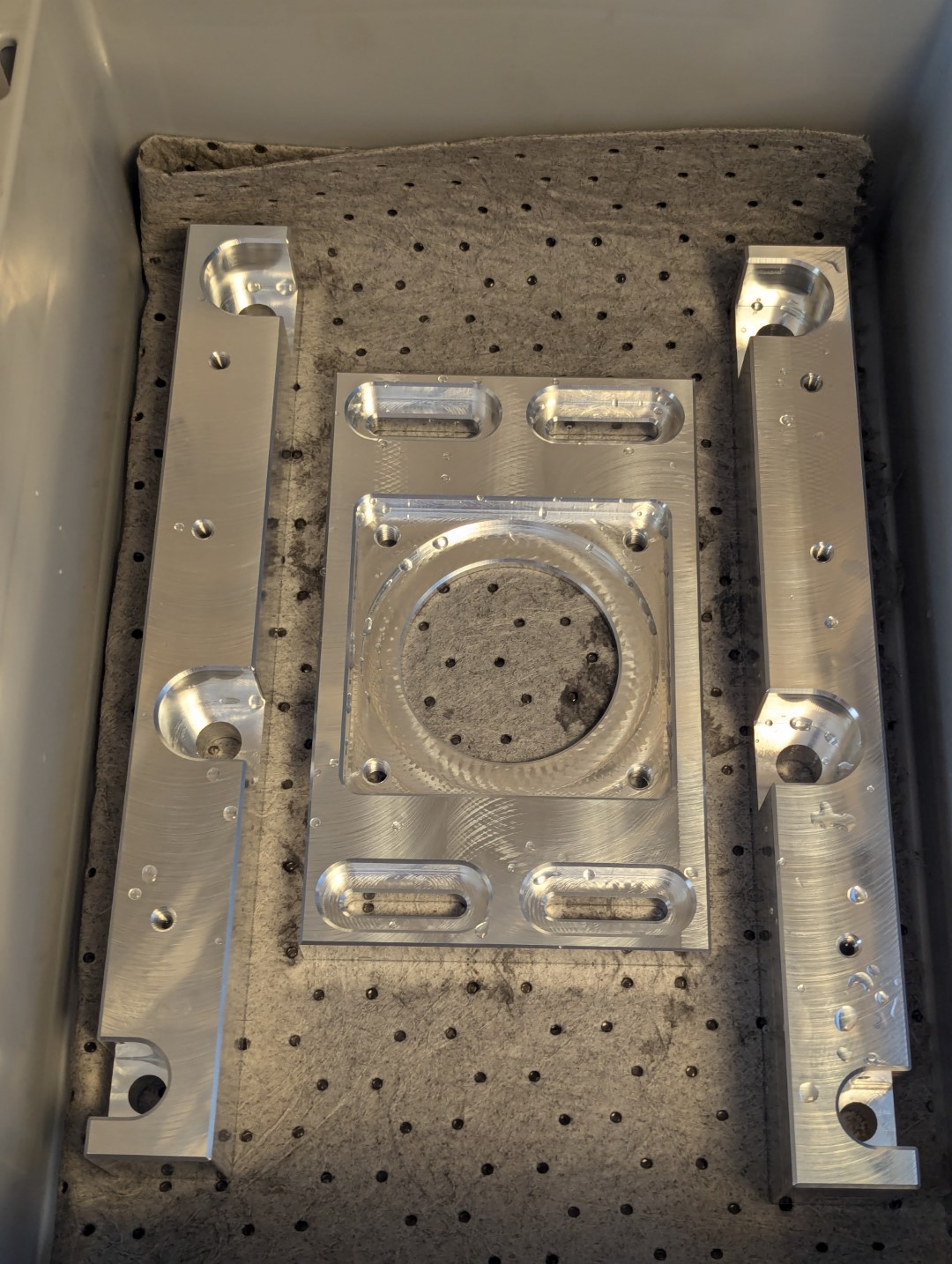

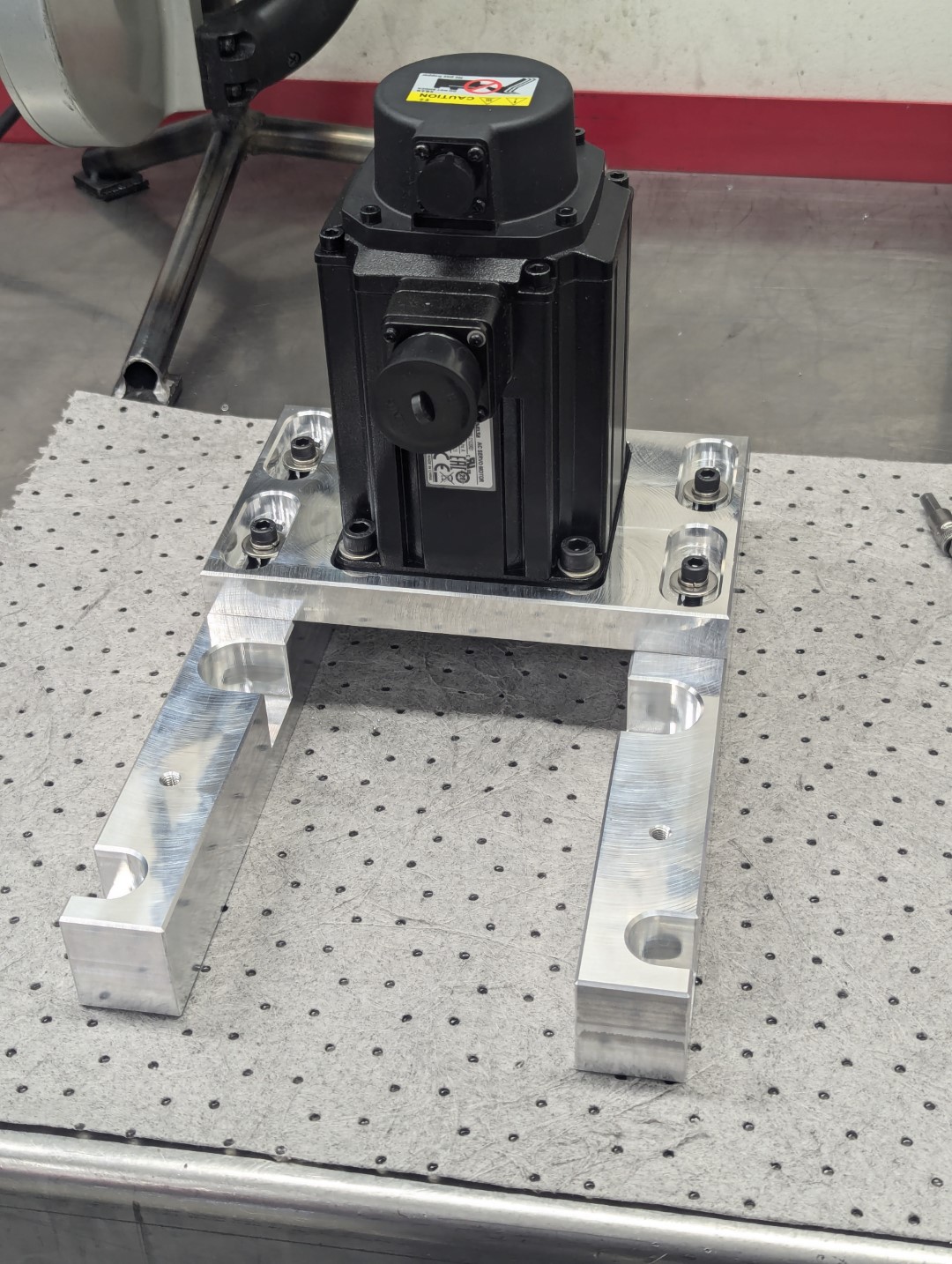

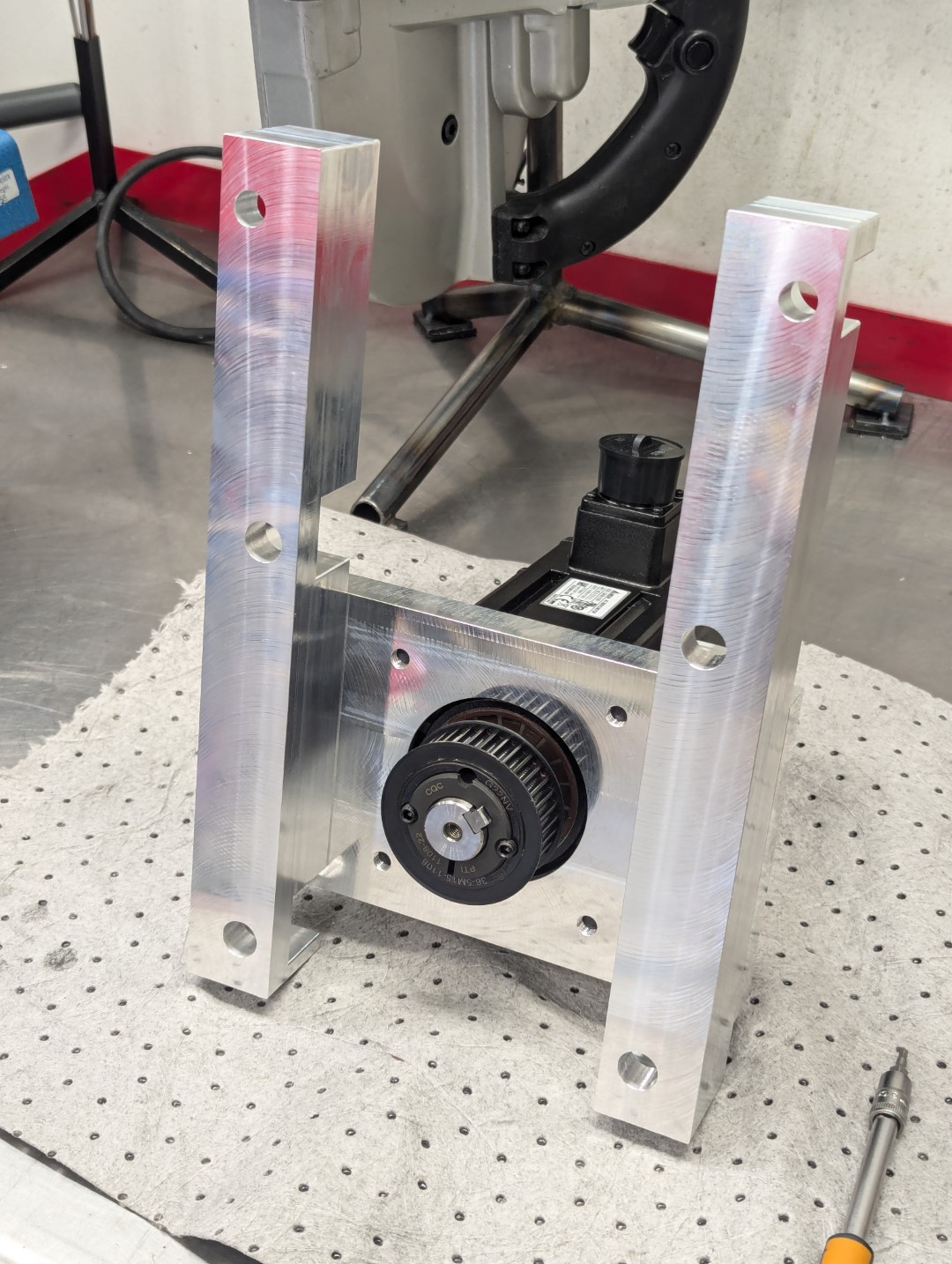

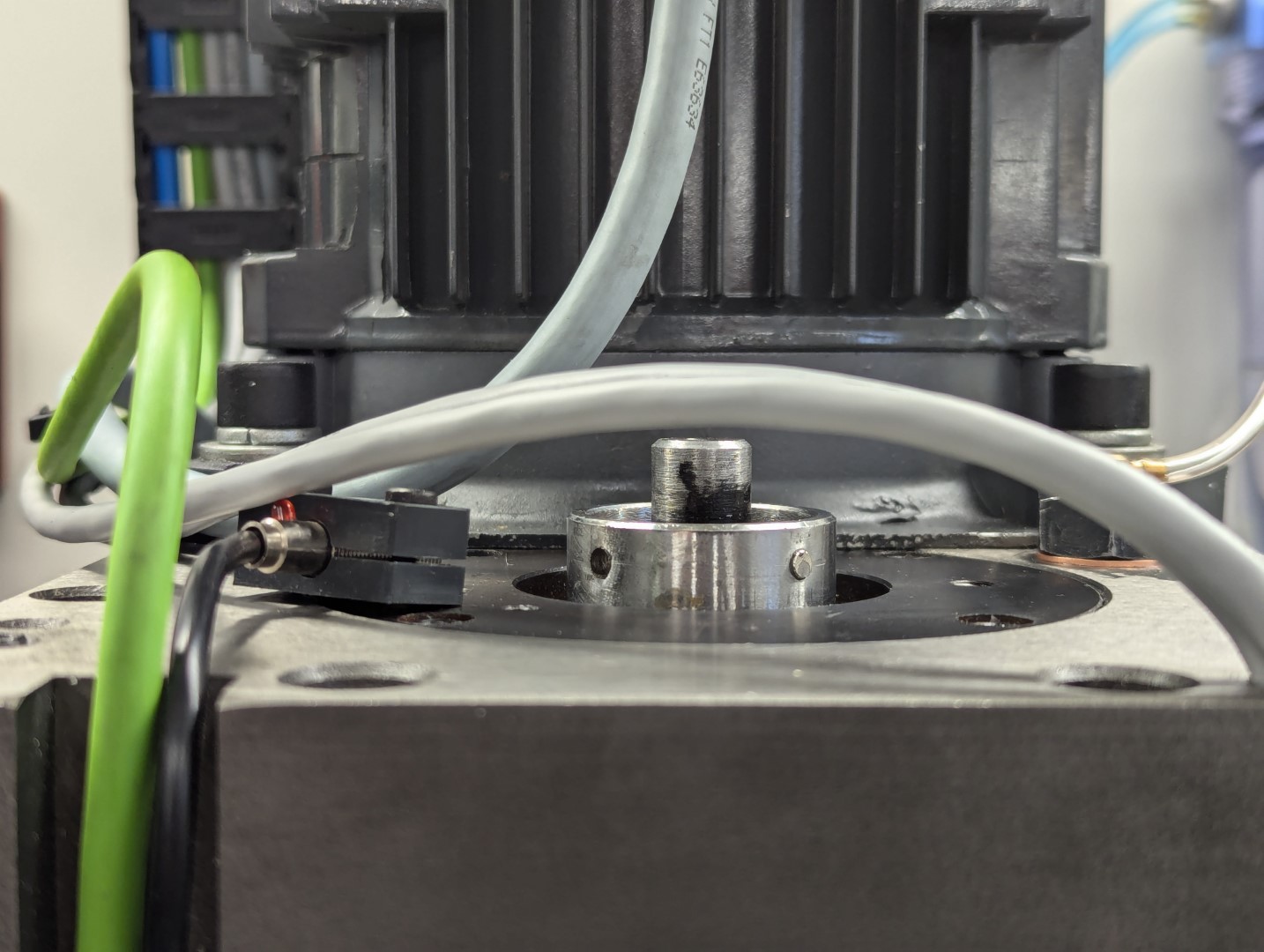

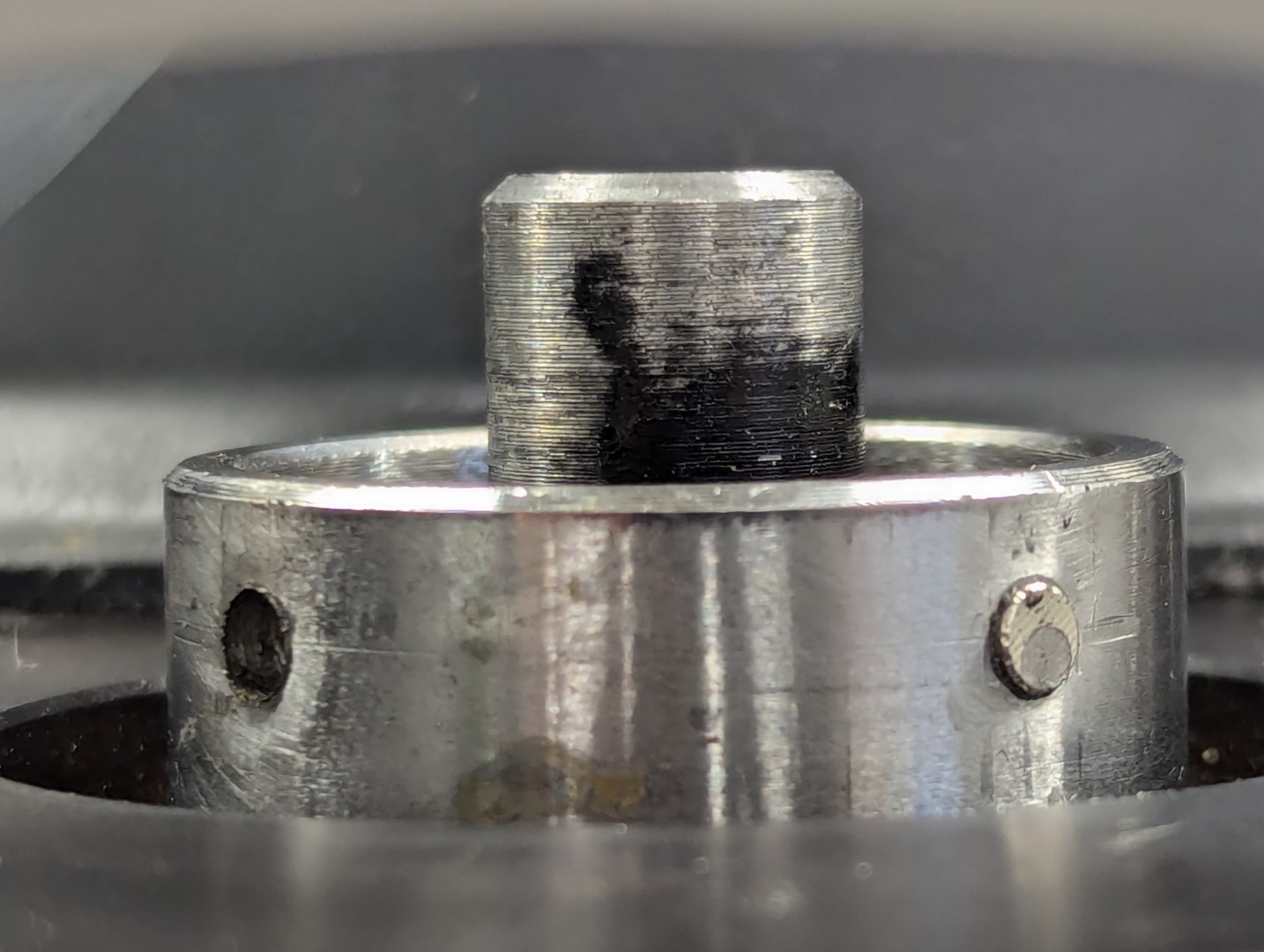

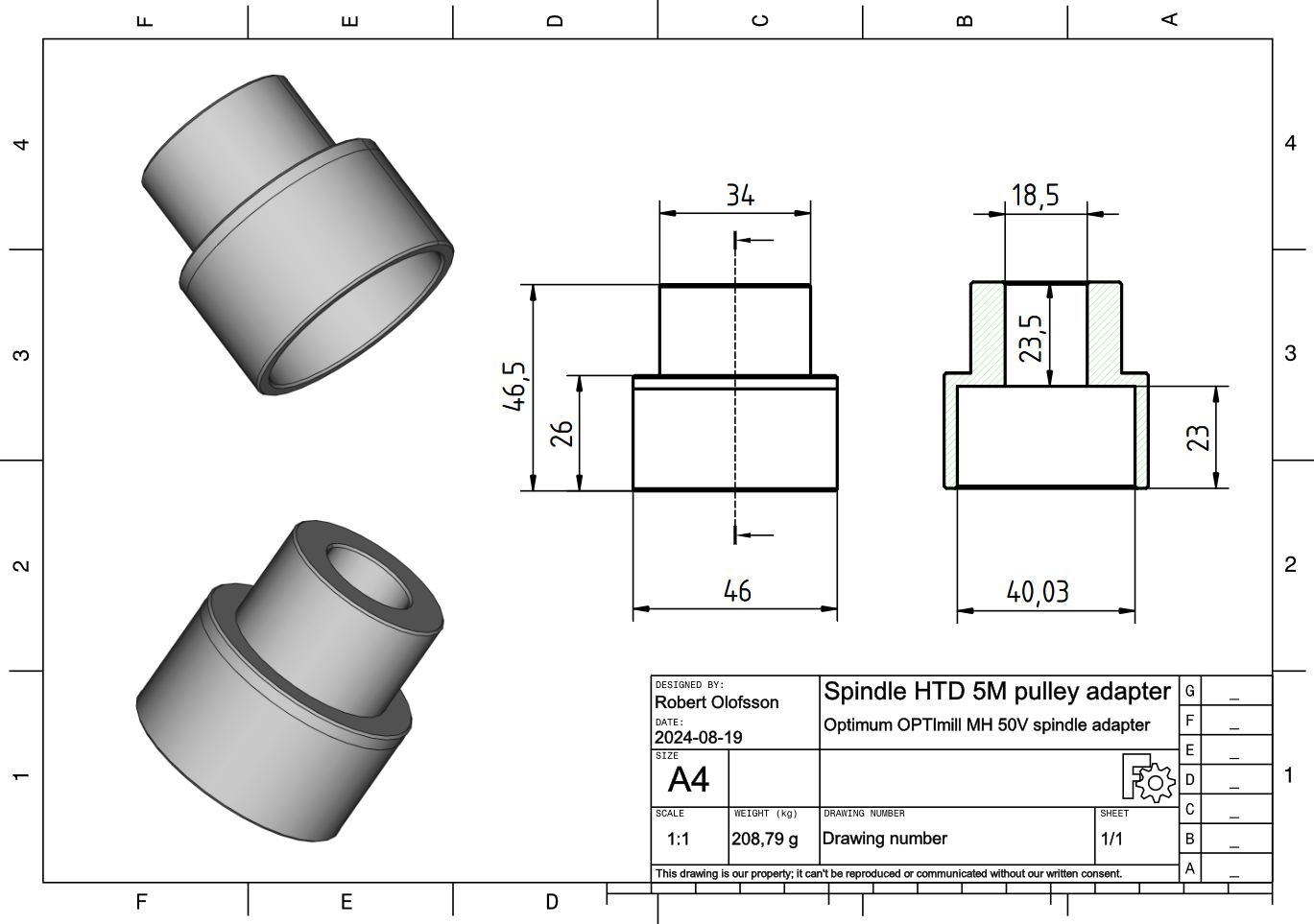

Replied by besriworld on topic Optimum Optimill MH50V CNC conversion

Optimum Optimill MH50V CNC conversion

Category: Milling Machines

- Unlogic

- Unlogic

10 Sep 2024 11:30 - 10 Sep 2024 11:33

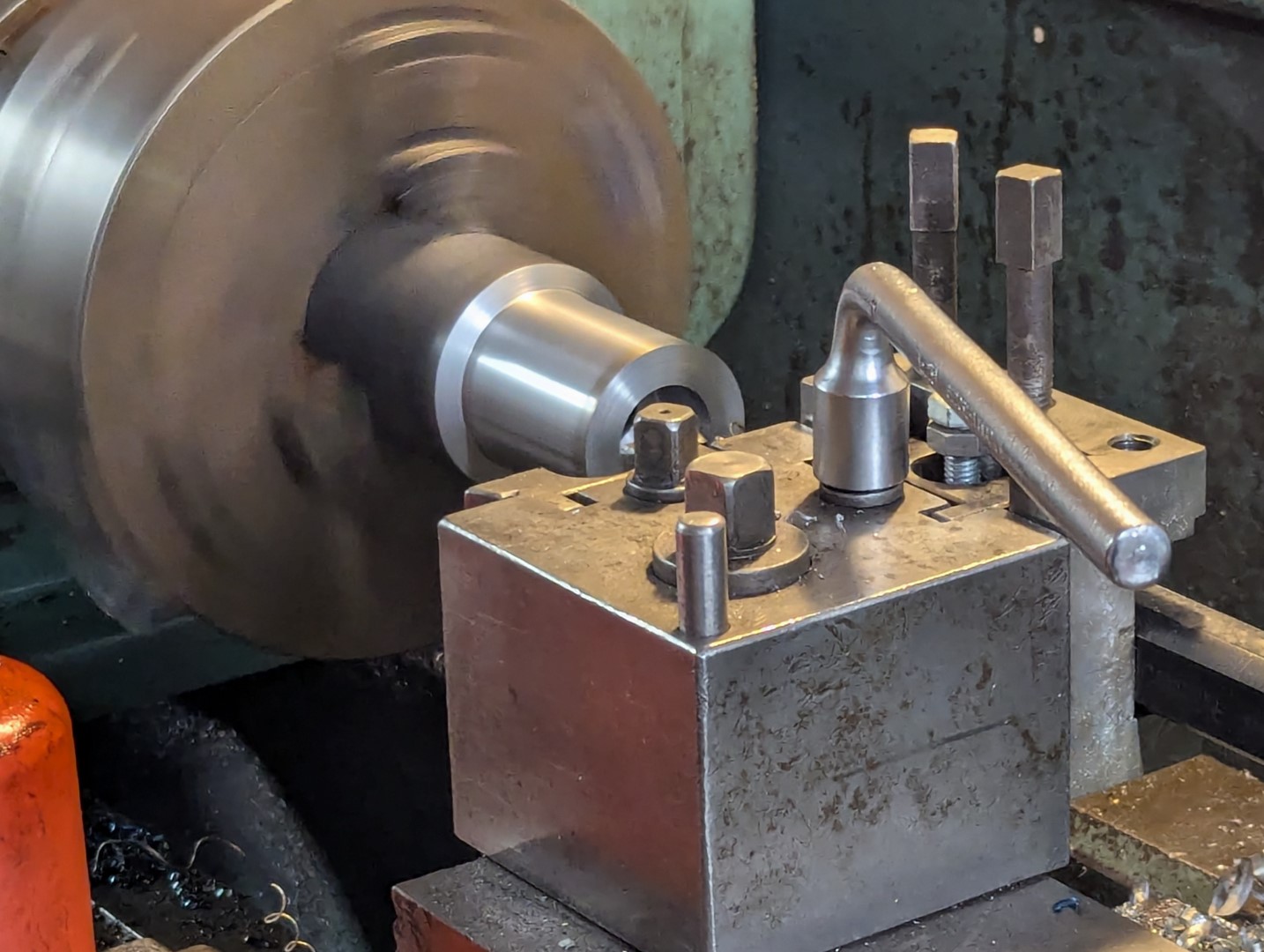

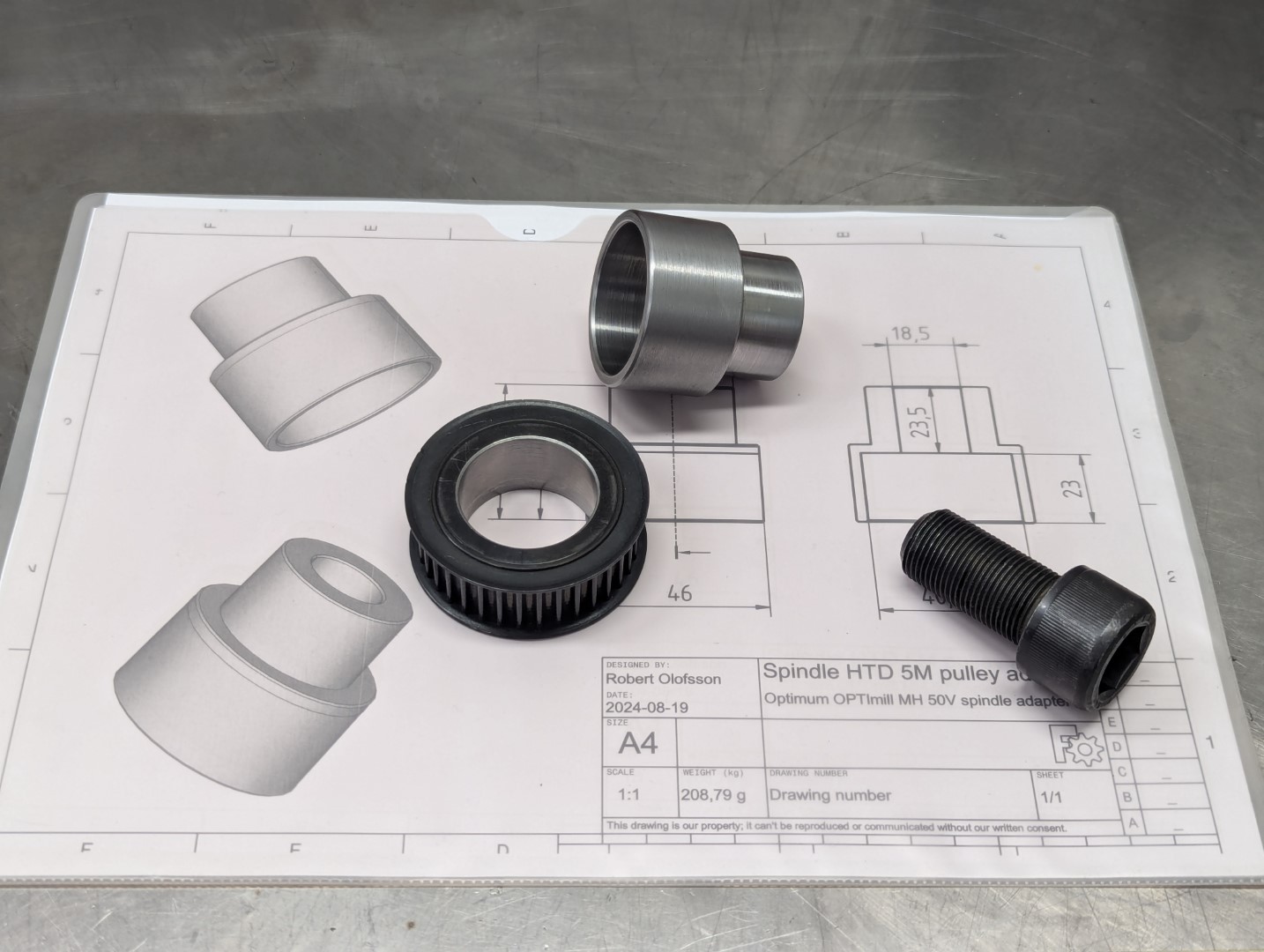

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

Optimum Optimill MH50V CNC conversion

Category: Milling Machines

- bertoldo

- bertoldo

10 Sep 2024 11:26 - 10 Sep 2024 11:55

Replied by bertoldo on topic Notes from installation of ethercat on Raspberry Pi 4

Notes from installation of ethercat on Raspberry Pi 4

Category: EtherCAT

- Unlogic

- Unlogic

10 Sep 2024 11:09

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

Optimum Optimill MH50V CNC conversion

Category: Milling Machines

- Abdulkareem

- Abdulkareem

10 Sep 2024 10:51

- Unlogic

- Unlogic

10 Sep 2024 10:49

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

Optimum Optimill MH50V CNC conversion

Category: Milling Machines

- Unlogic

- Unlogic

10 Sep 2024 10:31

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

Optimum Optimill MH50V CNC conversion

Category: Milling Machines

- pietxs

- pietxs

10 Sep 2024 10:25

Replied by pietxs on topic Maho MH-C 700P Achsen bewegen sich dauerhaft Indramat 3TRM2

Maho MH-C 700P Achsen bewegen sich dauerhaft Indramat 3TRM2

Category: Basic Configuration

- Unlogic

- Unlogic

10 Sep 2024 10:25

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

Optimum Optimill MH50V CNC conversion

Category: Milling Machines

- Unlogic

- Unlogic

10 Sep 2024 10:22

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

Optimum Optimill MH50V CNC conversion

Category: Milling Machines

- tivoi

10 Sep 2024 07:27

Replied by tivoi on topic Fanuc 2S AC spindle motor on Delta C2000+

Fanuc 2S AC spindle motor on Delta C2000+

Category: Milling Machines

- machinedude

10 Sep 2024 06:14

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

- besriworld

- besriworld

10 Sep 2024 06:06 - 10 Sep 2024 15:57

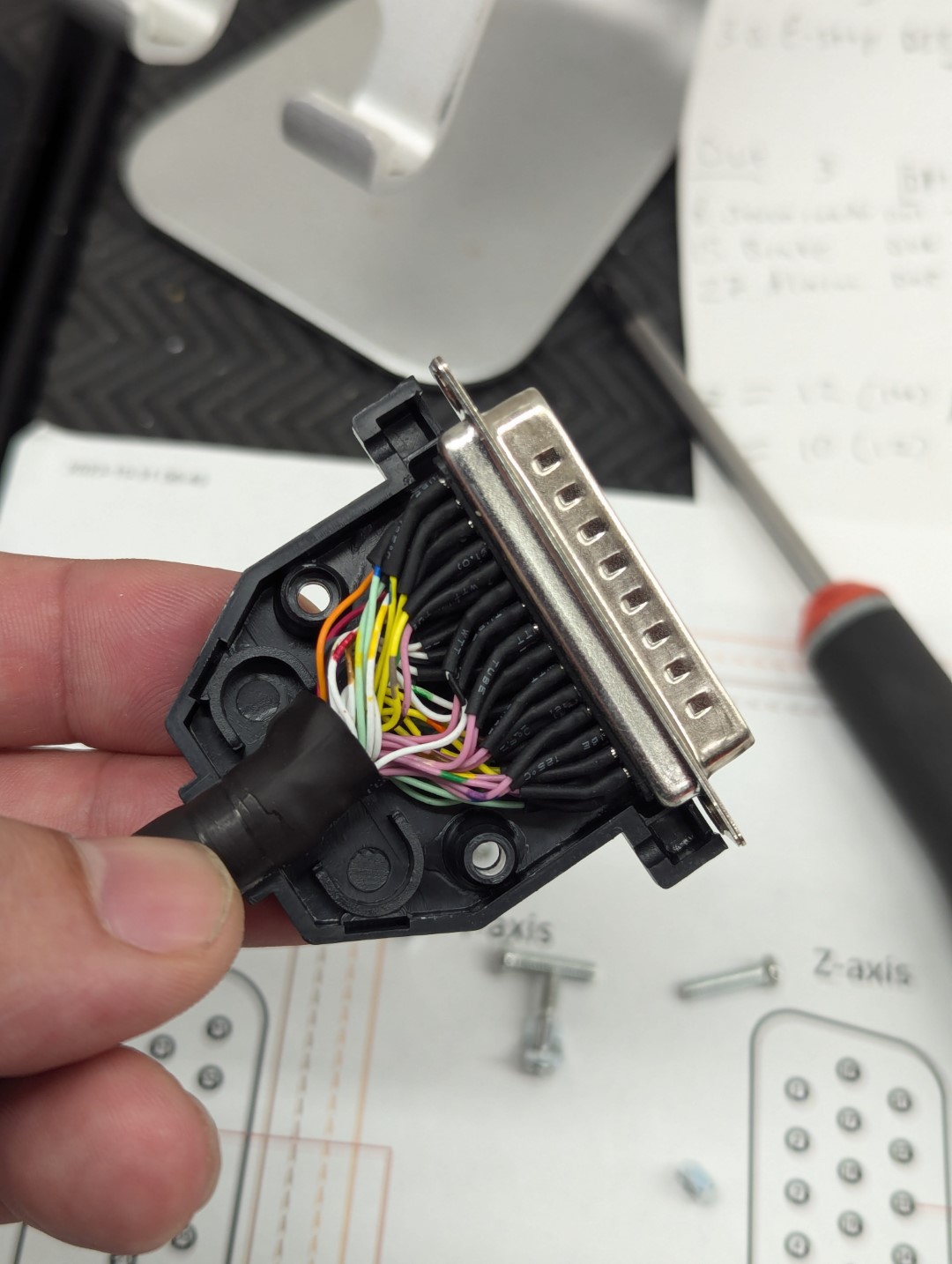

Replied by besriworld on topic Setting up 7i97t w idc26 bob

Setting up 7i97t w idc26 bob

Category: Driver Boards

Time to create page: 2.796 seconds