Search Results (Searched for: )

- Grotius

30 Jul 2024 11:41 - 30 Jul 2024 11:42

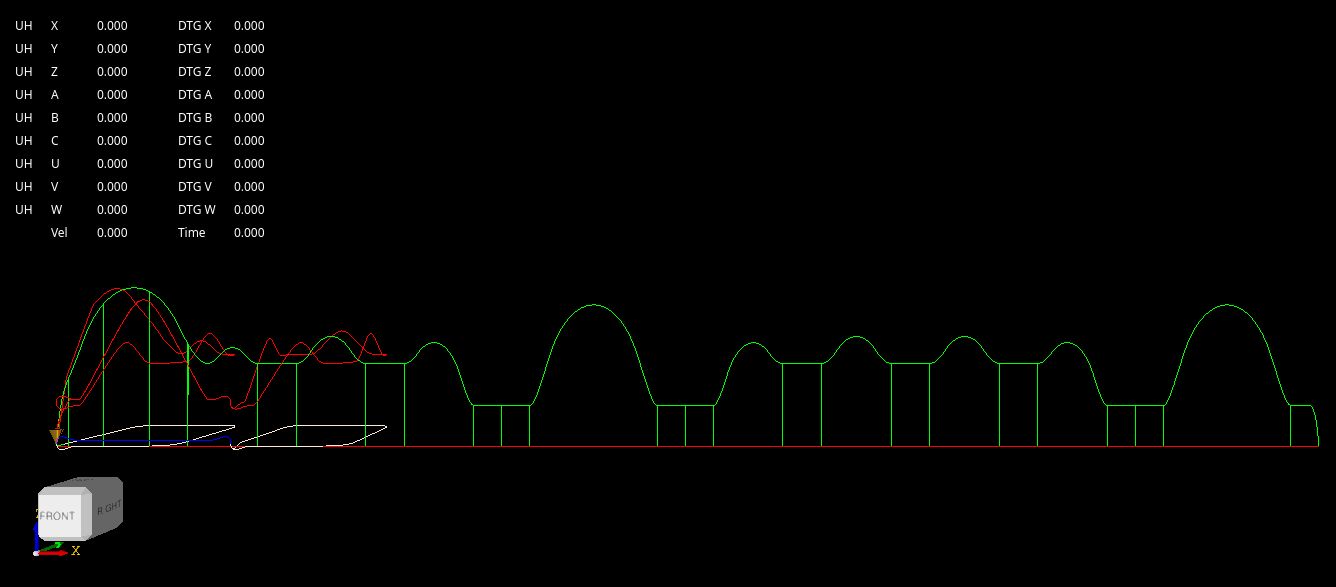

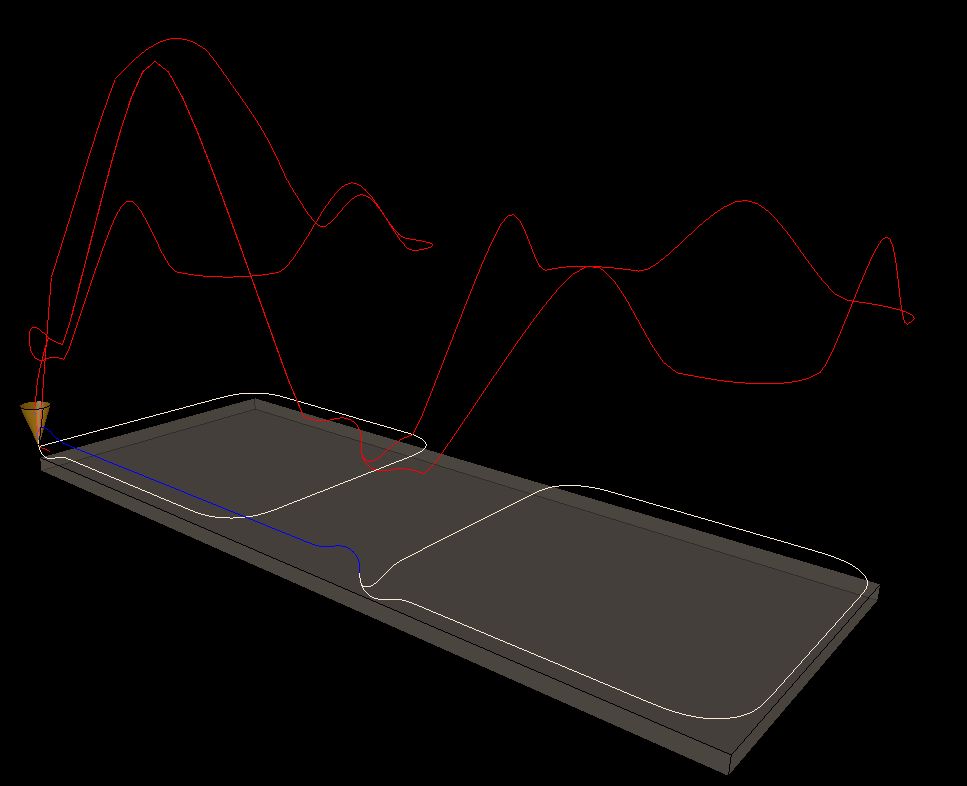

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- manfrel

- manfrel

30 Jul 2024 10:32

Replied by manfrel on topic Mesa 7i96s + DM556T -> Motors not moving

Mesa 7i96s + DM556T -> Motors not moving

Category: Driver Boards

- Lpkkk

- Lpkkk

30 Jul 2024 10:22 - 30 Jul 2024 14:46

Replied by Lpkkk on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- RotarySMP

30 Jul 2024 10:14

Replied by RotarySMP on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- besriworld

- besriworld

30 Jul 2024 10:03

Replied by besriworld on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- Krulli_Fräser

- Krulli_Fräser

30 Jul 2024 09:44

Replied by Krulli_Fräser on topic Verify my Mesa selection

Verify my Mesa selection

Category: Driver Boards

- Krulli_Fräser

- Krulli_Fräser

30 Jul 2024 09:43

Replied by Krulli_Fräser on topic Verify my Mesa selection

Verify my Mesa selection

Category: Driver Boards

- RotarySMP

30 Jul 2024 09:05

Replied by RotarySMP on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- Mecanix

- Mecanix

30 Jul 2024 08:49 - 30 Jul 2024 08:53

Replied by Mecanix on topic Who wants to use MODBUS ? Video.

Who wants to use MODBUS ? Video.

Category: Off Topic and Test Posts

- RotarySMP

30 Jul 2024 08:46

- rodw

30 Jul 2024 08:32

Replied by rodw on topic Help installing samba on Debian 12 Bookworm PREEMPT-RT ISO

Help installing samba on Debian 12 Bookworm PREEMPT-RT ISO

Category: General LinuxCNC Questions

- RotarySMP

30 Jul 2024 08:29

Replied by RotarySMP on topic Verify my Mesa selection

Verify my Mesa selection

Category: Driver Boards

- SertanATL

30 Jul 2024 08:20

Replied by SertanATL on topic Stepper Motor Tuning for Leadshine M542

Stepper Motor Tuning for Leadshine M542

Category: PnCConf Wizard

- peterdownunder

- peterdownunder

30 Jul 2024 08:00

- SertanATL

30 Jul 2024 07:26

Stepper Motor Tuning for Leadshine M542 was created by SertanATL

Stepper Motor Tuning for Leadshine M542

Category: PnCConf Wizard

Time to create page: 0.664 seconds