Search Results (Searched for: )

- langdons

- langdons

12 May 2025 15:20

Replied by langdons on topic Lathe for Sale in Virginia

Lathe for Sale in Virginia

Category: User Exchange

- andypugh

12 May 2025 14:51

- langdons

- langdons

12 May 2025 14:27

Replied by langdons on topic LinuxCNC compatible industrial PC

LinuxCNC compatible industrial PC

Category: Computers and Hardware

- langdons

- langdons

12 May 2025 14:17

Replied by langdons on topic LinuxCNC compatible industrial PC

LinuxCNC compatible industrial PC

Category: Computers and Hardware

- langdons

- langdons

12 May 2025 14:12 - 13 May 2025 12:31

Replied by langdons on topic Bridgeport VMC760 retrofit

Bridgeport VMC760 retrofit

Category: Milling Machines

- langdons

- langdons

12 May 2025 14:08

Replied by langdons on topic Bridgeport VMC760 retrofit

Bridgeport VMC760 retrofit

Category: Milling Machines

- Aciera

12 May 2025 13:45 - 12 May 2025 17:12

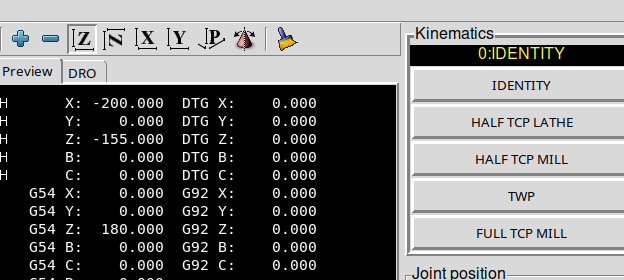

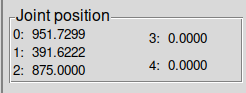

Replied by Aciera on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Category: Advanced Configuration

- Wischi

- Wischi

12 May 2025 12:09

Replied by Wischi on topic Gmoccapy Tool Change Dialog

Gmoccapy Tool Change Dialog

Category: Gmoccapy

- jochen91

- jochen91

12 May 2025 11:42

Replied by jochen91 on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Category: Advanced Configuration

- unknown

- unknown

12 May 2025 11:31

Replied by unknown on topic Off-the-shelf CNC control box with LinuxCNC?

Off-the-shelf CNC control box with LinuxCNC?

Category: Milling Machines

- Z3rni3

- Z3rni3

12 May 2025 10:49

- Aciera

12 May 2025 10:43

- my1987toyota

12 May 2025 10:41

Replied by my1987toyota on topic What are the chances of getting this setup working?

What are the chances of getting this setup working?

Category: Pick and Place

- spincycle

- spincycle

12 May 2025 10:31

Replied by spincycle on topic Bridgeport VMC760 retrofit

Bridgeport VMC760 retrofit

Category: Milling Machines

- electrosteam

- electrosteam

12 May 2025 10:12

Replied by electrosteam on topic Gmoccapy Tool Change Dialog

Gmoccapy Tool Change Dialog

Category: Gmoccapy

Time to create page: 0.289 seconds