- Configuring LinuxCNC

- Advanced Configuration

- Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

- jochen91

- Offline

- Senior Member

-

- Posts: 65

- Thank you received: 19

this is just outstanding! Also thank you so much for the Fanuc tool change example!

I could only try it out for one hour so far and I'm just amazed by the work and effort you done. Without your support, my decision of retrofitting this machine probably would be different! I also tried M19 R180. Worked flawlessly.

And as you correctly predicted i have a few questions so far:

1. Tool table:

The "Orient" and the "Diameter" for turning tools: Is it just informative, or is it used by some background calculations?

2. Tool rescue:

Assuming a drill or end mill doesn't sound right during milling and i stop the programming and want to retract it. When die B-axis is not at 0° it's quite difficult to get the tool out of a hole/pocket without braking it. A function to move the X axis at an B angle would be helpful for this.

That's it so far. I will try and implement the Fanuc tool change tomorrow and see where this will go. Again thank you so much and amazing work

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4648

- Thank you received: 2068

linuxcnc.org/docs/stable/html/lathe/lathe-user.html

To my knowledge, the values 'FRONT' 'BACK' 'ORIENT' are only used to change the tool display in the preview window.

2. Retraction of an oriented tool is quite simple:

- stop program execution

- change to MDI mode and execute 'g68.1'

- Jog the Z axis in the positive direction

I have modified the sim config and brought the 'TWP' button back to the right hand panel. Clicking on this should now define a TWP at the current tool orientation and position.

(G68.1 X#<_x> Y#<_y> Z#<_z>).

The folder has been updated:

forum.linuxcnc.org/10-advanced-configura...hine?start=50#328156

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

- Posts: 65

- Thank you received: 19

1. I tried to define the real machine limits in the .ini File. i.e. Z axis travel of 1065mm and home at zero. But after starting and homing z is automatically at -180mm.

2. While running the example part (which makes me happy every time i do it... thank you so much) i realized that the tool change position is defined by G53 in the M6 remap. But in the vismach sim it definitely looks different between T101 und T2. See pictures attached. I tried to do a G49 before the tool change call, but that made it worse. For the ATC the position of course need to be the same every time.

3. Does the kinematic has the prerequisite to work only if home is the position where both spindles are in line with each other? So X and Y between both spindles rotational axis is 0 ? I assume that is not the case.

And here are some topics I'm thinking about:

1. M19 R180/R0 works fine and is needed for the lathe tools. But I definitely need to write a custom component for this functionality, because the spindle is hydraulically locked and of course alot of logic needs to be implemented for this rotation.

I'm not sure yet how to implement it. My preference would be a custom G-code like i.e. G490 XXX (XXX = Degrees in multiples of 30°) that then calls the custom component. How does the Half TCP Lathe mode know the current tool orientation? As already said it works flawlessly with M19 but would it also work with G490 ?

2. I know it sounds a little bit stupid, but it would be nice if the tool rescue function would be limited to pressing the button TWP and then getting asked on how much the tool shall retraced in mm in z (only positive values accepted). Usually in those situations I'm nervous and don't want to wreck the spindle...

Kind regards,

Jochen

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4648

- Thank you received: 2068

1. I tried to define the real machine limits in the .ini File. i.e. Z axis travel of 1065mm and home at zero. But after starting and homing z is automatically at -180mm.

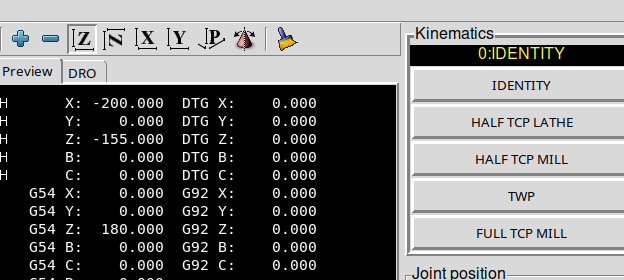

Changing machine limits in the ini will (and should not) change anything in the DRO at startup. I'm not sure where you see '-180' for Z. This is what I get:

2. While running the example part (which makes me happy every time i do it... thank you so much) i realized that the tool change position is defined by G53 in the M6 remap. But in the vismach sim it definitely looks different between T101 und T2.

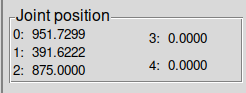

You might get confused about the difference in the tool path backplot (ie the pink line). This is purely a product of the visualization and comes from the different direction of the x and z tool-offsets for milling and turning. Absolute machine position is reflected by the values in the 'Joint Position' section in the right hand panel:

Note though that 'G53' (and also 'G28', G30') must only be used in 'IDENTITY' mode as the axis directions will follow the directions of the rotated axes in TCP modes or as defined in the TWP plane.

3. Does the kinematic has the prerequisite to work only if home is the position where both spindles are in line with each other? So X and Y between both spindles rotational axis is 0 ? I assume that is not the case.

The kinematic is setup with the pivot point of the spindle rotary to coincide with the machine reference point (ie joint positions all 0).

On a real machine config we can define the home positions (ie where a joint is 0) using the 'HOME_OFFSET' and 'HOME' values in the ini[JOINT_n] section. This is just not simulated in a simulation config.

1. M19 R180/R0 works fine and is needed for the lathe tools. But I definitely need to write a custom component for this functionality, because the spindle is hydraulically locked and of course alot of logic needs to be implemented for this rotation.

I'm not sure yet how to implement it. My preference would be a custom G-code like i.e. G490 XXX (XXX = Degrees in multiples of 30°) that then calls the custom component. How does the Half TCP Lathe mode know the current tool orientation? As already said it works flawlessly with M19 but would it also work with G490 ?

Currently the kinematic gets the spindle orientation through a hal connection to 'spindle.1.orient-angle'. This pin is set to the angle as requested by 'M19 R.... $1'. Because this value changes instantly it would likely cause a following error in the b-axis drive on the actual machine hence the note in the README about using actual spindle feed back (there are other HAL internal options to make this a gradual change inside hal if there is no real time feedback for the spindle position). So the kinematic just needs the orientation angle sent to the designated halpin 'mazak-integrex-200y-kins.tool-angle'.

2. I know it sounds a little bit stupid, but it would be nice if the tool rescue function would be limited to pressing the button TWP and then getting asked on how much the tool shall retraced in mm in z (only positive values accepted). Usually in those situations I'm nervous and don't want to wreck the spindle...

This is certainly possible.

Attachments:

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

- Posts: 65

- Thank you received: 19

My startup procedure is: Starting the configuration and homing. After that the Z Axis is at -180. See screenshot attached.

For the different tool change position:

Toolchange from no tool to lathe tool:

X-Axis-Position: 250mm

X-Joint-Position: 623.2051mm

Toolchange No. 2 from lathe tool to endmill:

X-Axis-Position: 330mm

X-Joint-Position: 873.2051mm

The Y-Joint-Position is the same.

Spindle orient:

"Because this value changes instantly it would likely cause a following error in the b-axis drive " that was the missing bit of information.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4648

- Thank you received: 2068

Seems your config homes at joint position 200 rather than 0, which is new.

Could you attach the ini file? (I notice that you have changed the z-offset to 0)i.e. Z axis travel of 1065mm and home at zero. But after starting and homing z is automatically at -180mm.

Re: Toolchange position.

I see this now. I'll need to investigate.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4648

- Thank you received: 2068

The issue is due to different G7/G8 status for tool changes in the example program. This is solved by forcing 'G8' in the tool change macro.

So change './remap_subs/m6remap.ngc' to this:

o<m6remap>sub

M66 L0 E0

M428

G8

G53 G0 X500 Y300 Z900

G53 G0 B-90

G53 Z500

M66 L0 E0

M6

G53 Z900

G53 X200

o<m6remap>endsub

m2Note that this macro is really only a rough sketch as it is, there are likely to be other issues.

Also note that this issue points out that the cgode program needs to set 'G7/G8' _after_ the tool change or, for a fancier solution, for the toolchange macro to restore the 'G7/G8'.

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

- Posts: 65

- Thank you received: 19

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4648

- Thank you received: 2068

o<m6remap>sub

M66 L0 E0

M428

; check if G7 is active

o100 if [#<_lathe_diameter_mode> EQ 1]

(print,DEBUG m6remap: G7 active)

#<g7g8_state> = 1

o100 else

(print,DEBUG m6remap: G8 active)

#<g7g8_state> = 0

o100 endif

G8

G53 G0 X500 Y300 Z900

G53 G0 B-90

G53 Z500

M66 L0 E0

M6

G53 Z900

G53 X200

; restore G7/G8 state

o101 if [#<g7g8_state> EQ 1]

(print,DEBUG m6remap: restoring G7)

G7

o101 else

(print,DEBUG m6remap: restoring G8)

G8

o101 endif

o<m6remap>endsub

m2Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

- Posts: 65

- Thank you received: 19

Z-Axis: 0 - 1065mm

Z-Joint: -1 - 1066mm

Thank you for the G7/G8 fix

Kind regards,

Jochen

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine