- Configuring LinuxCNC

- Advanced Configuration

- Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

- Aciera

-

- Offline

- Administrator

-

- Posts: 4616

- Thank you received: 2043

I just realized that your machine is actually more setup as a lathe so the above will not be much help.

The best way forward would likely be to build a new custom kinematic for your type of machine. I have a series of documentations (including the jupyter notebooks for sagemath) if you want to have a go at it:

github.com/Sigma1912/LinuxCNC_Demo_Confi...tating/Documentation

[edit]

If you attach your vismach model I'll see if I can find some time to help you.

Attachments:

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

- Posts: 63

- Thank you received: 19

I would be really happy if you could find the time and willpower to lift me up a little bit

I attached, hopefully my complete config incl. .comp & .py , config in the zip archive but just to be sure i attached my vismach config separately.

Kind regards,

Jochen

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4616

- Thank you received: 2043

1. unpack to your 'configs' folder

2. make sure that '/vismach/mazak-integrex-200y-gui.py' is marked as executable (right-click->Properties)

3. 'halcompile --install' the enclosed 'mazak_integrex_200y_kins.comp'

4. start the config and run the preloaded example gcode

Notes:

- Slide tilt angle and pivot-length can be set using the slider in the right hand panel.

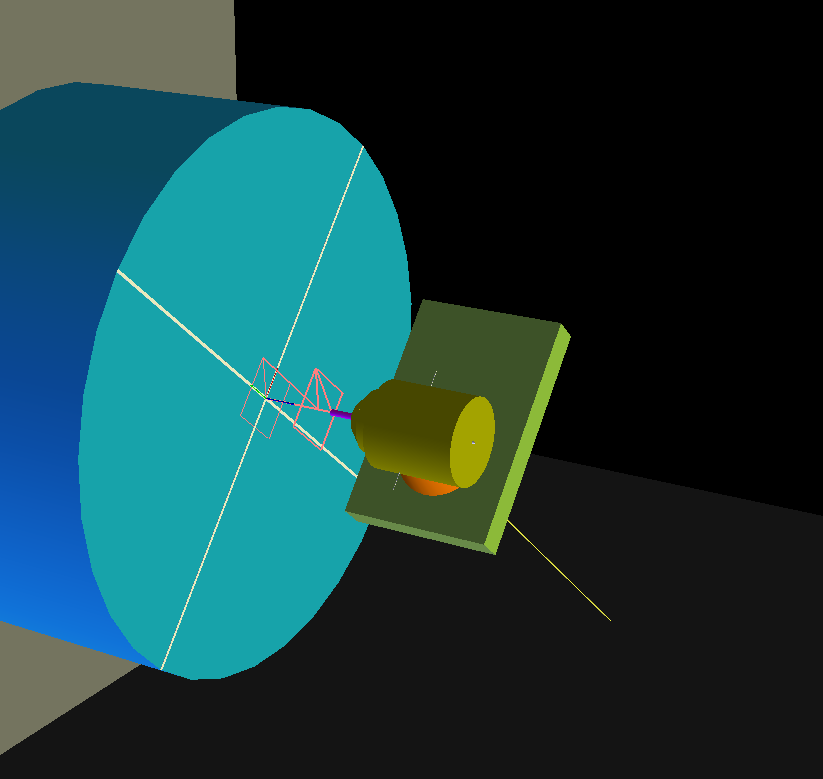

- the vismach model is a reused model from one of my other sim configs so it is a bit minimalistic but should suffice the purpose for now.

Attachments:

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

- Posts: 63

- Thank you received: 19

sorry for reply a bit late. I was on vaccation. Thank you so so much for this incredible help! I downloaded it and played i bit arround and it looks realy good.

I changed the travel limits for the B-Axis, because the head can swivel from "looking" left and right into the z direction. This caused some trouble. I need to spend more time with it to know what needs to be "polished".

Also i saw, that in the Identity Mode the Axis soft limits work fine, but in TCP-Mode the maschine runs into the joint hard limits.

I hope in find time during the weekend to dig myself further into your example. Thanks again for the amazing help!

Kind regards,

Jochen

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4616

- Thank you received: 2043

For non trivial kinematics proper limit checking prior to execution time is currently not possible because the planner is totally ignorant of custom kinematics. Your best option would be to check for limit violations in cam or running your gcode in a simulation configuration.Also i saw, that in the Identity Mode the Axis soft limits work fine, but in TCP-Mode the maschine runs into the joint hard limits.

Limit checking does work during execution (ie when the joint position actually exceeds the limit) but that will cause an immediate (emergency) stop.

Sometimes it may even be necessary to loosen axes limits to be able to reach the full work space.

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

- Posts: 63

- Thank you received: 19

just a quick update: At the Moment I'm in the process of aquerring the machine. The machine was listed in working condition. But sadly it has an error in the B-axis servo amp. The seller is realy cooperative and tries to fix it asap.

In the meantime i was thinking about to major "hurdles":

1.) Milling spindle orientation

The machine can hydraulically lock the spindle via hirth coupling in 12 positions. This is of course quite importent for tuning tools and broaching tools. Of course i want to implement this feature in LCNC as well. The first solution that came to my mind is using a custom M-Code that executes a custom HAL Component. The M-Code posting needs than to be implemented into the post processor after every tool change.

But i would prefer the solution by Mazak. They used iirc a custom tool change command and added the desired spindle angle.

It looked something like this: T01XX while XX equals the desired spindle orientation.

2. Turning spindle + C-axis + clamping I saw this is done via the PP so never mind.

There are plenty of examples on how to implement a lathe spindle + C-Axis in LCNC. What worries me is the spindle locking.

There is the INDEXER available, but this works only exclusivly with G0 moves. As soon as the G-code contains G0 CX and i.e. G1 CX FXX it does not work anymore. How can i solve this problem? My idea was to somehow use motmod.

C-axis can be locked if the next line of G-code does not move the axis and unlocked if the next line of code does. The question is how.

The bridge the waiting time for new posts on this topic here are some pictures:

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

- Posts: 63

- Thank you received: 19

during the last few days I thought about how to implement the PP and functionality of this machine.

I stumpeled across this pdf. Its from a Doosan Mill but it has the same construction as the Mazak and a PP is already there in Fusion. Now what came to my mind is how to drill holes if the B Axis is not oriented at 0° or 90°. Lets say at 45°. It uses a custom G-code G368 see page 40. I dont even have an idea how to implement this into LCNC but the question is do i need it? Couldn't it be done via TCP or kinematics?

I had to .zip the PDF. Otherwhise it would >1.6MB.

I would be super thankfull for some help, cause this is really a critical feature. I guess the same problem is not just drilling but also milling pockets at an angle other then 0° or 90°.

Kind regards,

Jochen

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4616

- Thank you received: 2043

But i would prefer the solution by Mazak. They used iirc a custom tool change command and added the desired spindle angle.

It looked something like this: T01XX while XX equals the desired spindle orientation.

This can be done using a remap of the 'M6' command.

I would be super thankfull for some help, cause this is really a critical feature. I guess the same problem is not just drilling but also milling pockets at an angle other then 0° or 90°.

This can be done using an additional custom kinematic and custom Gcodes that implement 'Tilted Work Plane' functionality.

For a demonstration see the sim config I linked earlier:

github.com/Sigma1912/LinuxCNC_Demo_Confi...lt/table_c-spindle_b

Note that your case probably only needs G68.3, G69 and a basic implementation of G53.1 (see link above for a description of these codes)

I'll have a look at expanding the mazak sim config in this respect.

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

- Posts: 63

- Thank you received: 19

i can't thank you enough! You know I'm not afraid of all the mechanics and electrics and getting the whole thing HAL ready also with custom M codes and custom Components I feel okay. But the kinematics and PP stuff... it scares me. I'm so glad that you help me so much on getting this thing to reality! I wish i could do more than just saying thanks a thousand times.

Kind regards,

Jochen

EDIT: I would be nice if two features could be added. An X Axis Tool offset is needed for lathe tooling. Also i dont know if the kinematics change, but the B axis can only rotate +/-90° while 0° is the tool looking straight down the X axis.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4616

- Thank you received: 2043

The machine can hydraulically lock the spindle via hirth coupling in 12 positions. This is of course quite importent for tuning tools and broaching tools.

I think I misunderstood this. I thought this applies to the B-axis but it seems to be the tool spindle.

Are you saying that the kinematic also needs to track the rotation of lathe or broaching tools in the tool spindle?

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine