- Configuring LinuxCNC

- Advanced Configuration

- Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

04 May 2025 15:05 #327681

by Aciera

Something I noticed looking at example #11 in the doosan manual:

(PREPARATION FOR START OF PROGRAM)

(INITIALIZE - RAPID, ZX PLANE, TNR COMP CANCEL, TLO CANCEL, CYCLE CANCEL, UPR FEED)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N3 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N4 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N5 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N6 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N7 M01

(PREPARATION FOR START OF OPERATION)

N8 G54 (WORK COORDINATE SELECTION)

N9 M06 T06006 (SANDVIK C6 ER32 COLLET HOLDER THRU COOLANT - 0.75 SOLID CARBIDE END MILL)

N10 T07000 (STAGE NEXT TOOL)

N11 M101 (LIVE B-AXIS SPINDLE - UNCLAMPED)

N12 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N13 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N14 M138 (SHOWER BED COOLANT ON)

N15 M126 (COOLANT THROUGH TOOL ON)

N16 M35 (LEFT SPINDLE C-AXIS MODE ON)

N17 G00 G28 H0.0 (ZERO RETURN C-AXIS)

N18 G97 S1500 M03 P12 (DIRECT RPM MODE - 500 RPM - B-AXIS SPINDLE CLOCKWISE)

N19 G00 C0.0

N20 G00 X8.0 Z4.0 (POSITION TO SAFE CLEARANCE)

N21 M89 (C-AXIS CLAMP)

N22 G00 Z1.0

(POSITION TO START POINT)

N23 X6.0

N24 Z-0.25

N25 Y-2.5

(MILL HEX FLAT AT C0.0)

N26 G01 X3.5 F0.0075

N27 Y2.5

N28 G00 X6.0

N29 M90 (C-AXIS UNCLAMP)

(MILL HEX FLAT AT C45.0)

N30 G00 C45.0

N31 M89 (C-AXIS CLAMP)

N32 Y-2.5

N33 G01 X3.5 F0.0075

N34 Y2.5

N35 G00 X6.0

N36 M90 (C-AXIS UNCLAMP)

(MILL HEX FLAT AT C90.0)

N37 G00 C90.0

N38 M89 (C-AXIS CLAMP)

N39 Y-2.5

N40 G01 X3.5 F0.0075

N41 Y2.5

N42 G00 X6.0

N43 M90 (C-AXIS UNCLAMP)

Note that in LinuxCNC G18 (and also G19) do not rotate the coordinate system but only the interpolation plane for arcs. This means that in Linuxcnc you cannot use 'G18' to change Z axis direction as the example code seems to imply. Instead you will have to use the 'Tilted work plane' codes to be able to use 'normal' xyz gcode (where xy is perpendicular to the tool rotational axis).

Replied by Aciera on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

I stumpeled across this pdf. Its from a Doosan Mill but it has the same construction as the Mazak and a PP is already there in Fusion.

Something I noticed looking at example #11 in the doosan manual:

Warning: Spoiler!

(PREPARATION FOR START OF PROGRAM)

(INITIALIZE - RAPID, ZX PLANE, TNR COMP CANCEL, TLO CANCEL, CYCLE CANCEL, UPR FEED)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N3 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N4 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N5 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N6 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N7 M01

(PREPARATION FOR START OF OPERATION)

N8 G54 (WORK COORDINATE SELECTION)

N9 M06 T06006 (SANDVIK C6 ER32 COLLET HOLDER THRU COOLANT - 0.75 SOLID CARBIDE END MILL)

N10 T07000 (STAGE NEXT TOOL)

N11 M101 (LIVE B-AXIS SPINDLE - UNCLAMPED)

N12 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N13 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N14 M138 (SHOWER BED COOLANT ON)

N15 M126 (COOLANT THROUGH TOOL ON)

N16 M35 (LEFT SPINDLE C-AXIS MODE ON)

N17 G00 G28 H0.0 (ZERO RETURN C-AXIS)

N18 G97 S1500 M03 P12 (DIRECT RPM MODE - 500 RPM - B-AXIS SPINDLE CLOCKWISE)

N19 G00 C0.0

N20 G00 X8.0 Z4.0 (POSITION TO SAFE CLEARANCE)

N21 M89 (C-AXIS CLAMP)

N22 G00 Z1.0

(POSITION TO START POINT)

N23 X6.0

N24 Z-0.25

N25 Y-2.5

(MILL HEX FLAT AT C0.0)

N26 G01 X3.5 F0.0075

N27 Y2.5

N28 G00 X6.0

N29 M90 (C-AXIS UNCLAMP)

(MILL HEX FLAT AT C45.0)

N30 G00 C45.0

N31 M89 (C-AXIS CLAMP)

N32 Y-2.5

N33 G01 X3.5 F0.0075

N34 Y2.5

N35 G00 X6.0

N36 M90 (C-AXIS UNCLAMP)

(MILL HEX FLAT AT C90.0)

N37 G00 C90.0

N38 M89 (C-AXIS CLAMP)

N39 Y-2.5

N40 G01 X3.5 F0.0075

N41 Y2.5

N42 G00 X6.0

N43 M90 (C-AXIS UNCLAMP)

Note that in LinuxCNC G18 (and also G19) do not rotate the coordinate system but only the interpolation plane for arcs. This means that in Linuxcnc you cannot use 'G18' to change Z axis direction as the example code seems to imply. Instead you will have to use the 'Tilted work plane' codes to be able to use 'normal' xyz gcode (where xy is perpendicular to the tool rotational axis).

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 19

04 May 2025 18:00 - 04 May 2025 18:10 #327697

by jochen91

Replied by jochen91 on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

The B Axis can be locked but also rotate freely for full simulatanious 5 axis milling.

The milling spindle in the B-axis can be locked in 12 positions for broaching and turning or rotate freely as a milling spindle.

I don't THINK that TCP needs to be applied for turning. To be honest im not particular sure. I know from a metal working perspective that an endmill can have z and x tool-offsets and turning tools can have x/y/and z. How and if that needs to be incorperated into the kinematic...?

Here is a link to see the machine in operation to get a better understanding what is possible:

Machining starts at roughly 4:51

Its a rather simple part for a Millturn but it gives at least a rough understanding of the operation of such a machine.

Tomorrow i wil work more with Fusion and the Doosan millturn PP and see what else of proprietary G-code will be posted.

The milling spindle in the B-axis can be locked in 12 positions for broaching and turning or rotate freely as a milling spindle.

I don't THINK that TCP needs to be applied for turning. To be honest im not particular sure. I know from a metal working perspective that an endmill can have z and x tool-offsets and turning tools can have x/y/and z. How and if that needs to be incorperated into the kinematic...?

Here is a link to see the machine in operation to get a better understanding what is possible:

Warning: Spoiler!

Machining starts at roughly 4:51

Its a rather simple part for a Millturn but it gives at least a rough understanding of the operation of such a machine.

Tomorrow i wil work more with Fusion and the Doosan millturn PP and see what else of proprietary G-code will be posted.

Last edit: 04 May 2025 18:10 by jochen91.

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 19

05 May 2025 07:47 - 05 May 2025 07:52 #327741

by jochen91

Replied by jochen91 on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

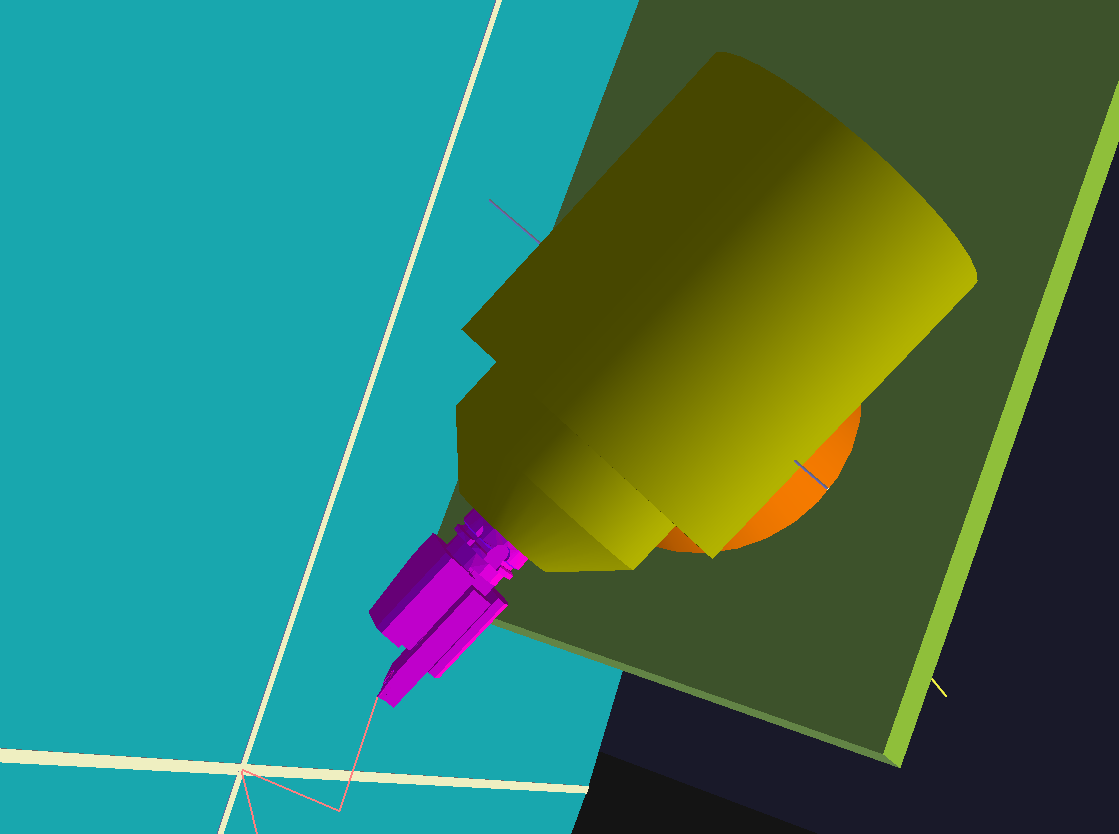

I did model up a test piece in Fusion:

The machine type selected in the PP was PUMA MX.

It look like only G400/G368/G17 and G18 is used.You said that G17,G18 and G368 can be replaced with G68.3 and G53.1 which i understand, but what about G400 ? (Functionality is documented in the .pdf). I think if those GCodes changes are implemented into the PP. The Doosan PP is sorta ready for LCNC (besides various M-codes).I can't test the TCP behavior of the PP since i don't have the manufacturing extension for Fusion.

Kind regards,

Jochen

The machine type selected in the PP was PUMA MX.

Warning: Spoiler!

%

O1001

G0 G18 G21 G40 G54 G80 G99

N1(TURNING)

G0 G28 U0. V0.

G53 Z0.

M90

G54

G99 G18 M34

G50 S5000

T0200

M6 T0200

T0100 (NEXT TOOL)

T0202

M8

G97 S374 M3 P11

G400 B0. J1. R3.

G0 Z5.

X170. Y0.

G96 S200 M3 P11

Z2.5

X140.

G1 Z-130.327 F1.

X150. Z-135.327

X152. Z-134.327

G0 Z2.5

X130.

G1 Z-125.327

X140. Z-130.327

X142. Z-129.327

G0 Z2.5

X120.

G1 Z-120.327

X130. Z-125.327

X132. Z-124.327

G0 Z2.5

X110.

G1 Z-115.327

X120. Z-120.327

X122. Z-119.327

G0 Z2.5

X100.

G1 Z-110.327

X110. Z-115.327

X112. Z-114.327

G0 Z2.5

X90.1

G1 Z-105.377

X100. Z-110.327

X102. Z-109.327

G0 Z2.5

X80.2

G1 Z-100.427

X90.1 Z-105.377

X92.1 Z-104.377

G0 X170.

Z5.

G97 S374 M3 P11

M9

G28 U0. V0.

G53 Z0.

N2(POCKET45)

G28 U0. V0.

G53 Z0.

M5 P11

G54

G98 G19 M35

G0 G28 H0.

M89

M6 T0100

T0300 (NEXT TOOL)

T0101

M8

G97 S5000 M3 P12

M90

G368 X0. Z0. D1. B-45. W1

G0 C90.

M89

G0 X-43.934 Y9.495 Z-127.988

X-73.934

G1 X-78.934 F333.33

X-112.358

X-112.729 Y9.512 Z-128.012

X-113.064 Y9.566 Z-128.078

X-113.196 Y9.614 Z-128.124

X-113.329 Y9.667 Z-128.163

X-113.414 Y9.74 Z-128.205

X-113.5 Y9.818 Z-128.236

X-113.529 Y9.908 Z-128.257

X-113.558 Y10. Z-128.264

Y10.666 F1000.

G3 Y10.985 Z-127.945 J0. K0.319

G1 Z-126.613

G3 Y10.666 Z-126.294 J-0.319 K0.

G1 Y-10.666

G3 Y-10.985 Z-126.613 J0. K-0.319

G1 Z-127.945

G3 Y-10.666 Z-128.264 J0.319 K0.

G1 Y10.

G2 Y11.426 Z-129.057 J0. K-1.679

G3 Y12.895 Z-129.01 J0.721 K0.448

Y12.995 Z-128.609 J-0.748 K0.4

G1 Z-124.603

G3 Y12.676 Z-124.284 J-0.319 K0.

G1 Y-12.676

G3 Y-12.995 Z-124.603 J0. K-0.319

G1 Z-129.955

G3 Y-12.676 Z-130.274 J0.319 K0.

G1 Y12.676

G3 Y12.995 Z-129.955 J0. K0.319

G1 Z-128.609

G2 Y14.748 Z-125.981 J2.848 K0.

G3 Y16.5 Z-123.352 J-1.095 K2.629

G1 Z-122.279

G3 Y15. Z-120.779 J-1.5 K0.

G1 Y-15.

G3 Y-16.5 Z-122.279 J0. K-1.5

G1 Z-132.279

G3 Y-15. Z-133.779 J1.5 K0.

G1 Y15.

G3 Y16.5 Z-132.279 J0. K1.5

G1 Z-123.352

X-113.529 Y16.49 Z-123.26

X-113.5 Y16.466 Z-123.17

X-113.414 Y16.433 Z-123.094

X-113.329 Y16.388 Z-123.023

X-113.196 Y16.346 Z-122.972

X-113.064 Y16.299 Z-122.925

X-112.729 Y16.231 Z-122.874

X-112.358 Y16.206 Z-122.859

G0 X-43.934

M5 P12

M90

M9

G28 U0. V0.

G53 Z0.

G369

N3(DRILLING 2D POCKET45)

G28 U0. V0.

G53 Z0.

G54

G98 G19

G0 G28 H0.

M89

M6 T0300

T0100 (NEXT TOOL)

T0303

M8

G97 S5000 M3 P12

M90

G368 X0. Z0. D1. B-45. W3

G0 C90.

M89

G0 X136.066 Y0. Z-127.279

X116.066

X-104.558

G1 X-144.558 F1000.

G0 X116.066

X136.066

M5 P12

M90

M9

G28 U0. V0.

G53 Z0.

G369

N4(HEX_MILLING IN XY)

G28 U0. V0.

G53 Z0.

G54

G98 G17

G0 G28 H0.

M89

M6 T0100

T0200 (NEXT TOOL)

T0101

M8

G97 S5000 M3 P12

M90

G400 B-90. J0.

M101

G0 C0.

M89

G0 X-1.2 Y44.8 Z15.

Z5.

G1 Z1. F333.33

Z-29.4

G19 G2 Y44.2 Z-30. J-0.6 K0. F1000.

G1 Y43.6

G17 G3 X0. Y43. I0.6 J0.

G2 X3. Y42.598 I0. J-3.

G1 X72.282 Y22.598

G2 X75.282 Y20. I-1.5 J-2.598

G1 Y-20.

G2 X72.282 Y-22.598 I-3. J0.

G1 X3. Y-42.598

G2 X-3. I-1.5 J2.598

G1 X-72.282 Y-22.598

G2 X-75.282 Y-20. I1.5 J2.598

G1 Y20.

G2 X-72.282 Y22.598 I3. J0.

G1 X-3. Y42.598

G2 X0. Y43. I1.5 J-2.598

G3 X1.2 Y43.6 I0. J0.6

G1 Y44.2

G19 G3 Y44.8 Z-29.4 J0. K0.6

G0 Z15.

(HEX_MILLING_C_AXIS)

M90

G400 B0. J0.

M101

G0 C120.

M89

G1 X180. Y-21.2 Z-27. F12000.

G0 X160.

G1 X152. F333.33

X70.482

G17 G2 X69.282 Y-20.6 I0. J0.6 F1000.

G1 Y-20.

Y20.

Y20.6

G2 X70.482 Y21.2 I0.6 J0.

G0 X180.

(HEX_MILLING_C_AXIS)

M90

G400 B0. J0.

M101

G0 C180.

M89

G1 X180. Y-21.2 Z-27. F12000.

G0 X160.

G1 X152. F333.33

X70.482

G2 X69.282 Y-20.6 I0. J0.6 F1000.

G1 Y-20.

Y20.

Y20.6

G2 X70.482 Y21.2 I0.6 J0.

G0 X180.

(HEX_MILLING_C_AXIS)

M90

G400 B0. J0.

M101

G0 C240.

M89

G1 X180. Y-21.2 Z-27. F12000.

G0 X160.

G1 X152. F333.33

X70.482

G2 X69.282 Y-20.6 I0. J0.6 F1000.

G1 Y-20.

Y20.

Y20.6

G2 X70.482 Y21.2 I0.6 J0.

G0 X180.

(HEX_MILLING_C_AXIS)

M90

G400 B0. J0.

M101

G0 C300.

M89

G1 X180. Y-21.2 Z-27. F12000.

G0 X160.

G1 X152. F333.33

X70.482

G2 X69.282 Y-20.6 I0. J0.6 F1000.

G1 Y-20.

Y20.

Y20.6

G2 X70.482 Y21.2 I0.6 J0.

G0 X180.

(HEX_MILLING_C_AXIS)

M90

G400 B0. J0.

M101

G0 C0.

M89

G1 X180. Y-21.2 Z-27. F12000.

G0 X160.

G1 X152. F333.33

X70.482

G2 X69.282 Y-20.6 I0. J0.6 F1000.

G1 Y-20.

Y20.

Y20.6

G2 X70.482 Y21.2 I0.6 J0.

G0 X180.

(HEX_MILLING_C_AXIS)

M90

G400 B0. J0.

M101

G0 C60.

M89

G1 X180. Y-21.2 Z-27. F12000.

G0 X160.

G1 X152. F333.33

X70.482

G2 X69.282 Y-20.6 I0. J0.6 F1000.

G1 Y-20.

Y20.

Y20.6

G2 X70.482 Y21.2 I0.6 J0.

G0 X180.

(POCKET AROUND C)

M90

M272 (Y-AXIS INTERLOCK RELEASE)

G400 B0. J0.

G0 C-3.148

Z-69.291

X120. Y0. Z-69.291

T0100

G700 D001 (ENABLE TCP)

M101

G1 X119.819 Y-3.295 Z-69.291 B0. C-3.148 F12000.

X99.849 Y-2.746

X94.857 Y-2.608 F333.33

X72.091 Y-1.982

X71.719 Y-1.987 Z-69.267 C-3.172

X71.38 Y-2.026 Z-69.201 C-3.249

X71.104 Y-2.109 Z-69.116 C-3.395

X70.918 Y-2.237 Z-69.043 C-3.61

X70.838 Y-2.397 Z-69.015 C-3.871

X70.612 Y-3.706 C-5.993 F1000.

X70.289 Y-5.011 C-8.115

X70.231 Y-5.209 Z-69.109 C-8.438

X70.207 Y-5.292 Z-69.334 C-8.572

Z-70.666

X70.231 Y-5.209 Z-70.891 C-8.438

X70.289 Y-5.011 Z-70.985 C-8.115

X70.6 Y-3.764 C-6.086

X70.822 Y-2.512 C-4.057

X70.956 Y-1.256 C-2.028

X71. Y0. C0.

X70.955 Y1.257 C2.029

X70.822 Y2.512 C4.058

X70.6 Y3.764 C6.087

X70.289 Y5.012 C8.116

X70.231 Y5.21 Z-70.891 C8.439

X70.207 Y5.292 Z-70.666 C8.573

Z-69.334

X70.231 Y5.21 Z-69.109 C8.439

X70.289 Y5.012 Z-69.015 C8.116

X70.527 Y4.091 C6.618

X70.717 Y3.168 C5.119

X70.858 Y2.242 C3.621

X70.951 Y1.315 C2.122

X70.996 Y0.387 C0.624

X70.992 Y-0.542 C-0.874

X70.939 Y-1.47 C-2.373

X70.838 Y-2.397 C-3.871

X70.755 Y-2.949 Z-68.891 C-4.765

X70.67 Y-3.417 Z-68.538 C-5.523

X70.607 Y-3.73 Z-68.01 C-6.031

X70.538 Y-4.042 Z-67.482 C-6.538

X70.425 Y-4.508 Z-67.129 C-7.296

X70.276 Y-5.057 Z-67.005 C-8.19

X70.009 Y-5.909 C-9.582

X69.702 Y-6.758 C-10.975

X69.621 Y-6.963 Z-67.103 C-11.312

X69.587 Y-7.048 Z-67.338 C-11.451

Z-72.662

X69.621 Y-6.963 Z-72.897 C-11.312

X69.702 Y-6.758 Z-72.995 C-10.975

X70.005 Y-5.922 C-9.603

X70.269 Y-5.082 C-8.231

X70.492 Y-4.24 C-6.859

X70.675 Y-3.395 C-5.487

X70.817 Y-2.548 C-4.115

X70.919 Y-1.699 C-2.743

X70.98 Y-0.85 C-1.371

X71. Y0. C0.

X70.98 Y0.85 C1.372

X70.919 Y1.7 C2.744

X70.817 Y2.548 C4.116

X70.675 Y3.395 C5.488

X70.492 Y4.24 C6.86

X70.268 Y5.083 C8.232

X70.005 Y5.923 C9.604

X69.701 Y6.759 C10.976

X69.621 Y6.964 Z-72.897 C11.313

X69.586 Y7.049 Z-72.662 C11.453

Z-67.338

X69.621 Y6.964 Z-67.103 C11.313

X69.701 Y6.759 Z-67.005 C10.976

X69.969 Y6.029 C9.778

X70.205 Y5.296 C8.58

X70.412 Y4.561 C7.382

X70.587 Y3.824 C6.184

X70.731 Y3.086 C4.986

X70.845 Y2.346 C3.789

X70.927 Y1.605 C2.591

X70.979 Y0.863 C1.393

X71. Y0.121 C0.195

X70.989 Y-0.621 C-1.003

X70.948 Y-1.363 C-2.201

X70.875 Y-2.104 C-3.399

X70.772 Y-2.845 C-4.596

X70.637 Y-3.584 C-5.794

X70.472 Y-4.321 C-6.992

X70.276 Y-5.057 C-8.19

X70.063 Y-5.748 Z-66.891 C-9.318

X69.844 Y-6.38 Z-66.559 C-10.354

X69.645 Y-6.903 Z-66.036 C-11.212

X69.494 Y-7.274 Z-65.364 C-11.823

X69.364 Y-7.576 Z-64.858 C-12.322

X69.168 Y-8.013 Z-64.508 C-13.044

X68.922 Y-8.527 Z-64.359 C-13.897

X68.654 Y-9.051 Z-64.429 C-14.771

X68.4 Y-9.518 Z-64.711 C-15.553

X68.201 Y-9.869 Z-65.167 C-16.141

X68.189 Y-9.889 Z-65.205 C-16.175

X68.119 Y-10.011 Z-65.618 C-16.379

X68.086 Y-10.066 Z-66.196 C-16.472

Z-73.804

X68.119 Y-10.011 Z-74.382 C-16.379

X68.189 Y-9.889 Z-74.795 C-16.175

X68.316 Y-9.669 Z-75.214 C-15.804

X68.49 Y-9.356 Z-75.602 C-15.281

X68.713 Y-8.937 Z-75.95 C-14.581

X68.984 Y-8.4 Z-76.241 C-13.687

X69.272 Y-7.783 Z-76.426 C-12.665

X69.598 Y-7.019 Z-76.5 C-11.404

X70.027 Y-5.856 C-9.494

X70.379 Y-4.686 C-7.585

X70.652 Y-3.511 C-5.675

X70.847 Y-2.331 C-3.766

X70.963 Y-1.15 C-1.856

X71. Y0.033 C0.053

X70.958 Y1.216 C1.963

X70.838 Y2.397 C3.872

X70.642 Y3.56 C5.755

X70.37 Y4.718 C7.638

X70.022 Y5.872 C9.521

X69.598 Y7.019 C11.403

X69.273 Y7.783 Z-76.426 C12.665

X68.984 Y8.4 Z-76.241 C13.687

X68.713 Y8.937 Z-75.95 C14.581

X68.49 Y9.356 Z-75.602 C15.281

X68.316 Y9.668 Z-75.214 C15.804

X68.19 Y9.889 Z-74.795 C16.175

X68.119 Y10.011 Z-74.381 C16.379

X68.086 Y10.067 Z-73.803 C16.473

Z-66.197

X68.119 Y10.011 Z-65.619 C16.379

X68.19 Y9.889 Z-65.205 C16.175

X68.316 Y9.668 Z-64.786 C15.804

X68.49 Y9.356 Z-64.398 C15.281

X68.713 Y8.937 Z-64.05 C14.581

X68.984 Y8.4 Z-63.759 C13.687

X69.273 Y7.783 Z-63.574 C12.665

X69.598 Y7.019 Z-63.5 C11.403

X69.926 Y6.151 C9.978

X70.21 Y5.279 C8.552

X70.451 Y4.404 C7.127

X70.649 Y3.527 C5.702

X70.802 Y2.647 C4.276

X70.912 Y1.766 C2.851

X70.978 Y0.883 C1.425

X71. Y0. C0.

X70.978 Y-0.883 C-1.426

X70.912 Y-1.766 C-2.851

X70.802 Y-2.647 C-4.276

X70.649 Y-3.527 C-5.702

X70.451 Y-4.405 C-7.127

X70.21 Y-5.28 C-8.553

X69.926 Y-6.151 C-9.978

X69.598 Y-7.019 C-11.404

X69.272 Y-7.783 Z-63.574 C-12.665

X68.984 Y-8.4 Z-63.759 C-13.687

X68.713 Y-8.937 Z-64.05 C-14.581

X68.49 Y-9.356 Z-64.398 C-15.281

X68.316 Y-9.669 Z-64.786 C-15.804

X68.201 Y-9.869 Z-65.167 C-16.141

X68.213 Y-9.91 Z-65.266 C-16.201

X68.304 Y-9.932 Z-65.363 C-16.216

X68.458 Y-9.944 Z-65.439 C-16.2

X68.653 Y-9.958 Z-65.486 C-16.177

X68.865 Y-9.982 Z-65.502 C-16.167

X115.255 Y-16.706 F12000.

G49

G701 (DISABLE TCP)

M273 (Y-AXIS INTERLOCK RELEASE OFF)

M5 P12

M9

G0 G28 U0. V0.

G53 Z0.

G0 G28 H0.

M89

M34

G54

M30

%It look like only G400/G368/G17 and G18 is used.You said that G17,G18 and G368 can be replaced with G68.3 and G53.1 which i understand, but what about G400 ? (Functionality is documented in the .pdf). I think if those GCodes changes are implemented into the PP. The Doosan PP is sorta ready for LCNC (besides various M-codes).I can't test the TCP behavior of the PP since i don't have the manufacturing extension for Fusion.

Kind regards,

Jochen

Last edit: 05 May 2025 07:52 by jochen91.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

05 May 2025 08:58 - 05 May 2025 08:58 #327744

by Aciera

Replied by Aciera on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Looks like G368/G369 can be handled by the TWP functionality.

G400 is different as it transforms the tool offset rather than the tool position.

I'm not very familiar with cnc turning so I have little idea how linuxcnc handles the tool orientation as set in 'R' and 'K' words. There is this document which also refers to tool orientation but I have really no idea if this is actually used in motion planning or only in the GUI.

linuxcnc.org/docs/html/lathe/lathe-user.html

I'd say it's certainly possible to recreate this using a python remap.

Note though that even Doosan suggest that it is more accurate to touch off the tool at the b-axis angle used in the operation.

G400 is different as it transforms the tool offset rather than the tool position.

I'm not very familiar with cnc turning so I have little idea how linuxcnc handles the tool orientation as set in 'R' and 'K' words. There is this document which also refers to tool orientation but I have really no idea if this is actually used in motion planning or only in the GUI.

linuxcnc.org/docs/html/lathe/lathe-user.html

I'd say it's certainly possible to recreate this using a python remap.

Note though that even Doosan suggest that it is more accurate to touch off the tool at the b-axis angle used in the operation.

Last edit: 05 May 2025 08:58 by Aciera.

The following user(s) said Thank You: jochen91

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 19

05 May 2025 13:09 #327756

by jochen91

Replied by jochen91 on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Hello,

so after some digging around i found the Doosan G Code explanation sheet. I uploaded it into my GitHub so everybody can access it. It was a pain in the **** to get it.

github.com/jochenr91/Integrex

It explains every G-code the machine accepts. Including G400 starting on Page 155 (Page 157 with example pictures).

Also interessting: The Doosan Machine exepts G68:

Three-dimensional coordinate conversion without B-axis rotating (G68.1/G69.1)

Three-dimensional coordinate conversion with B-axis rotating (G368/G369)

The question is how to implement it into the PP or replace G400 in the PP. I get the benefits of using G400. But i don't need this functionality, at least to get things running. On the long run of course it would be quite nice, cause this is one of the huge benefits of a mill turn. Since this G code works with the tool offsets automatically it should be used by the motion planner?!

But yes the touch off should be at B0.

so after some digging around i found the Doosan G Code explanation sheet. I uploaded it into my GitHub so everybody can access it. It was a pain in the **** to get it.

github.com/jochenr91/Integrex

It explains every G-code the machine accepts. Including G400 starting on Page 155 (Page 157 with example pictures).

Also interessting: The Doosan Machine exepts G68:

Three-dimensional coordinate conversion without B-axis rotating (G68.1/G69.1)

Three-dimensional coordinate conversion with B-axis rotating (G368/G369)

The question is how to implement it into the PP or replace G400 in the PP. I get the benefits of using G400. But i don't need this functionality, at least to get things running. On the long run of course it would be quite nice, cause this is one of the huge benefits of a mill turn. Since this G code works with the tool offsets automatically it should be used by the motion planner?!

But yes the touch off should be at B0.

The following user(s) said Thank You: Aciera

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 19

06 May 2025 10:39 #327840

by jochen91

Replied by jochen91 on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

I thought a little bit about it and came to the conclusion, that most of the functionality of the Millturn would be covered with the following G-codes:

G68.1/G69.1

G368/G369

G400

G490 (I think, I could do that myself by replacing the G code with a custom M code in the PP)

Do you think you could support me on more time ?

Kind regards,

Jochen

G68.1/G69.1

G368/G369

G400

G490 (I think, I could do that myself by replacing the G code with a custom M code in the PP)

Do you think you could support me on more time ?

Kind regards,

Jochen

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

06 May 2025 12:19 #327846

by Aciera

Replied by Aciera on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

I'm still working on it.

Having the tool pointing in the x direction instead of the z direction in the home position has turned out to be a bit more of a headache as Linuxcnc applies the tool offsets internally.

TCP with xyz tool offset and tool spindle orientation is done. The kinematic for Tilted work plane also works but the transformation of the work offset still needs some work.

Let me figure this out first and I'll post a new sim config so you can have a look at it. Then we can have a look at customizing the gcodes for your specific needs.

Having the tool pointing in the x direction instead of the z direction in the home position has turned out to be a bit more of a headache as Linuxcnc applies the tool offsets internally.

TCP with xyz tool offset and tool spindle orientation is done. The kinematic for Tilted work plane also works but the transformation of the work offset still needs some work.

Let me figure this out first and I'll post a new sim config so you can have a look at it. Then we can have a look at customizing the gcodes for your specific needs.

Attachments:

The following user(s) said Thank You: besriworld, jochen91

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

07 May 2025 07:56 #327927

by Aciera

Replied by Aciera on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Could you export the example part from your post here as an stl file and post it here?

forum.linuxcnc.org/10-advanced-configura...hine?start=40#327741

forum.linuxcnc.org/10-advanced-configura...hine?start=40#327741

Please Log in or Create an account to join the conversation.

- jochen91

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 19

07 May 2025 08:53 - 07 May 2025 08:54 #327929

by jochen91

Replied by jochen91 on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

I exported it in STL and OBJ. I had problems getting Fusion STL export into vismach. OBJ worked flawless. Thank you!

Last edit: 07 May 2025 08:54 by jochen91.

The following user(s) said Thank You: Aciera

Please Log in or Create an account to join the conversation.

- meister

- Offline

- Platinum Member

-

Less

More

- Posts: 703

- Thank you received: 430

07 May 2025 09:24 #327931

by meister

Replied by meister on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

there are two versions of STL files, ASCII and Binary, you have a binary file and vismach can only read the ASCII format

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Time to create page: 0.245 seconds