Search Results (Searched for: )

- PCW

29 Apr 2025 21:37

- ffffrf

- ffffrf

29 Apr 2025 21:19

- scotta

29 Apr 2025 21:12

- PCW

29 Apr 2025 20:57 - 29 Apr 2025 22:25

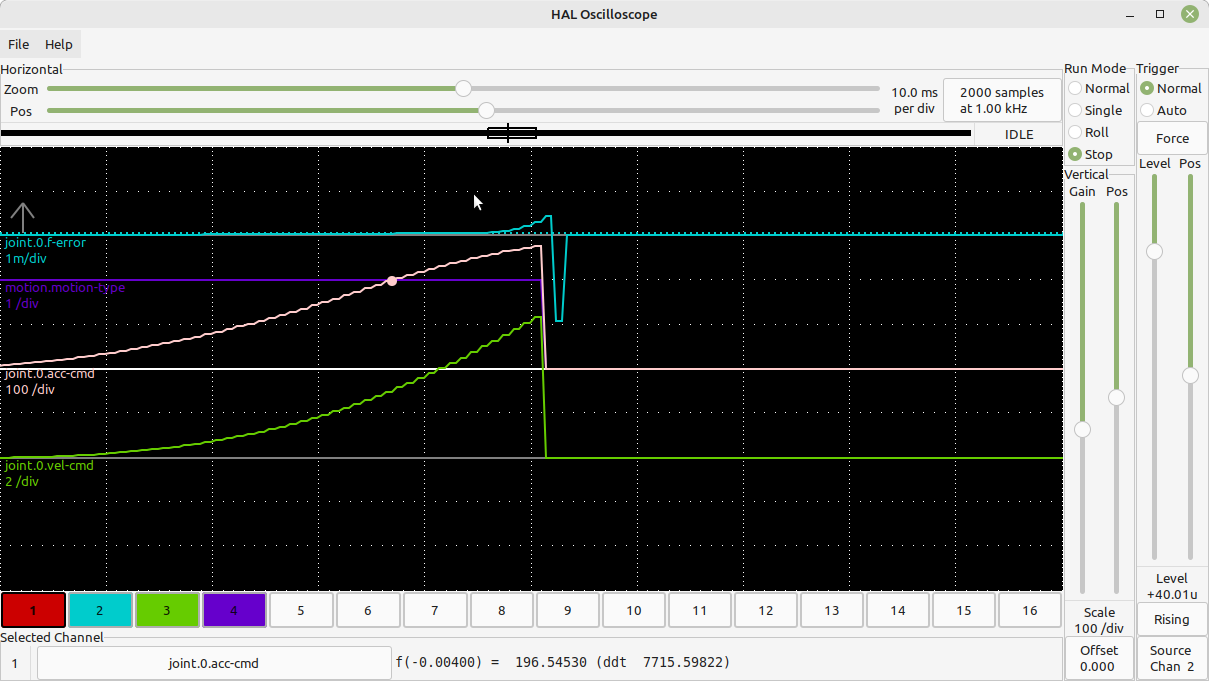

Replied by PCW on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- Daz

- Daz

29 Apr 2025 20:26

Replied by Daz on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Daz

- Daz

29 Apr 2025 20:20

Replied by Daz on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Giovanni

- Giovanni

29 Apr 2025 19:44

Replied by Giovanni on topic NativeCam on LinuxCNC 2.9.3

NativeCam on LinuxCNC 2.9.3

Category: NativeCAM

- atrex77

29 Apr 2025 19:25 - 29 Apr 2025 19:26

Replied by atrex77 on topic Developing a Raspberry Pi Pico-based I/O Board for LinuxCNC

Developing a Raspberry Pi Pico-based I/O Board for LinuxCNC

Category: General LinuxCNC Questions

- cakeslob

- cakeslob

29 Apr 2025 18:49

Replied by cakeslob on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

- DarkPhoinix

- DarkPhoinix

29 Apr 2025 18:45 - 29 Apr 2025 19:00

Replied by DarkPhoinix on topic [SOLVED]linuxcnc Latency test ambiguous results

[SOLVED]linuxcnc Latency test ambiguous results

Category: General LinuxCNC Questions

- Attis92

- Attis92

29 Apr 2025 18:23

Replied by Attis92 on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- MarkoPolo

- MarkoPolo

29 Apr 2025 18:17

Replied by MarkoPolo on topic [SOLVED]linuxcnc Latency test ambiguous results

[SOLVED]linuxcnc Latency test ambiguous results

Category: General LinuxCNC Questions

- PCW

29 Apr 2025 17:33

Replied by PCW on topic Using npn Inductive sensor for end stop.

Using npn Inductive sensor for end stop.

Category: Basic Configuration

- cakeslob

- cakeslob

29 Apr 2025 17:03

Replied by cakeslob on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- santy

- santy

29 Apr 2025 16:24 - 29 Apr 2025 16:28

EtherCAT + 7i96s + Internet Success was created by santy

EtherCAT + 7i96s + Internet Success

Category: EtherCAT

Time to create page: 0.488 seconds