Danke für deine Antwort Timo

Der GND und +5VP sind allerdings Ausgänge für Encoder, zB Glasmaßstäbe die selber keine Stromquelle haben.

Der Encoder vom Servo bekommt aber Strom von der Endstufe und benötigt GND und 5VP nicht, allerdings sollte man darauf achten das die angeschlossenen Komponenten das gleiche Potential haben, deswegen habe ich gestern auf Rat eines Elektronikers GND vom 24V und 5V Netzteil zusammengelegt. Gebracht hat es aber auch nichts.

Ich bekomme diesen Encoder nicht ans laufen und habe absolut keinen Dunst, warum nicht.

Der Servoencoder selbst sollte funktionieren weil in der Endstufe die aktuelle Drehzahl angezeigt wird, reagiert auch sofort auf Drehen von Hand.

Seit ihr bitte so freundlich und schaut euch meine Hal und Ini Einträge dafür mal an ob da ein Fehler drin ist?

# Verwendete LinuxCNC version: Master (2.9)

# Mesa 7i76 LAUFT IN MODE 1 MIT 4 ANALOGEN EINGANGEN (sserial_port_0=1000000x) !!!!!!

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT unlock_joints_mask=0x8 servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS num_dio=6 num_aio=3

loadrt hostmot2

loadrt hm2_eth board_ip="10.10.10.10" config="num_encoders=6 num_pwmgens=0 num_stepgens=5 sserial_port_0=1000000x"

loadrt flipflop count=2

setp hm2_7i92.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.z

addf hm2_7i92.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf hm2_7i92.0.write servo-thread

setp hm2_7i92.0.dpll.01.timer-us -50

setp hm2_7i92.0.stepgen.timer-number 1

#*******************

# SPINDEL

#*******************

setp hm2_7i92.0.encoder.05.counter-mode 0

setp hm2_7i92.0.encoder.05.filter 1

setp hm2_7i92.0.encoder.05.index-invert 0

setp hm2_7i92.0.encoder.05.index-mask 0

setp hm2_7i92.0.encoder.05.index-mask-invert 0

setp hm2_7i92.0.encoder.05.scale [SPINDLE_0]ENCODER_SCALE

setp hm2_7i92.0.stepgen.04.dirsetup [SPINDLE_0]DIRSETUP

setp hm2_7i92.0.stepgen.04.dirhold [SPINDLE_0]DIRHOLD

setp hm2_7i92.0.stepgen.04.steplen [SPINDLE_0]STEPLEN

setp hm2_7i92.0.stepgen.04.stepspace [SPINDLE_0]STEPSPACE

setp hm2_7i92.0.stepgen.04.position-scale [SPINDLE_0]OUTPUT_SCALE

setp hm2_7i92.0.stepgen.04.step_type 0

setp hm2_7i92.0.stepgen.04.control-type 1

setp hm2_7i92.0.stepgen.04.maxaccel [SPINDLE_0]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.04.maxvel [SPINDLE_0]STEPGEN_MAXVEL

net spindle-vel-cmd-rpm => hm2_7i92.0.stepgen.04.velocity-cmd

net spindle-enable => hm2_7i92.0.stepgen.04.enable => hm2_7i92.0.7i76.0.0.output-06

net spindle-index-enable => hm2_7i92.0.encoder.05.index-enable

net spindle-revs <= hm2_7i92.0.encoder.05.position

net spindle-vel-fb-rps <= hm2_7i92.0.encoder.05.velocity

net spindle-rpm <= hm2_7i92.0.encoder.05.velocity-rpm

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

Ich habe Teile der Hal ausgelassen die absolut nichts mit der Spindel zu tun haben um die zu kürzen

Hier die INI-Einträge

[EMC]

VERSION = 1.1

MACHINE = Hera

DEBUG = 0

[DISPLAY]

DISPLAY = probe_basic_lathe

LATHE = 1

CONFIRM_EXIT = False

LOG_FILE = sim.log

LOG_LEVEL = DEBUG

PREFERENCE_FILE = sim.pref

CONFIG_FILE = custom_config.yml

CYCLE_TIME = 0.100

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 6.00000

MAX_LINEAR_VELOCITY = 166.000000

MIN_LINEAR_VELOCITY = 0.500000

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

DEFAULT_SPINDLE_SPEED = 300

MAX_SPINDLE_OVERRIDE = 2.000000

MIN_SPINDLE_OVERRIDE = 0.500000

MAX_FEED_OVERRIDE = 2.000000

PROGRAM_PREFIX = ~/linuxcnc/nc_files

OPEN_FILE = ~/linuxcnc/nc_files/pb_examples/blank.ngc

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 1

INCREMENTS = JOG 5mm 1mm .5mm .1mm .05mm .01mm .005mm

GEOMETRY = xz

USER_TABS_PATH = user_tabs/

[SPINDLE_0]

# Stepgeneratoreinstellungen

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 1000

STEPSPACE = 1000

STEPGEN_MAXVEL = 3000

STEPGEN_MAXACCEL = 1000

# Encoder

ENCODER_SCALE = 10000

OUTPUT_SCALE = 166.0667

# Berechnung: 10000 / 60 = 166.06666667 (Endocer Impulse pro Umdrehung durch 60 = Impulse pro Sekunde Output Scale)

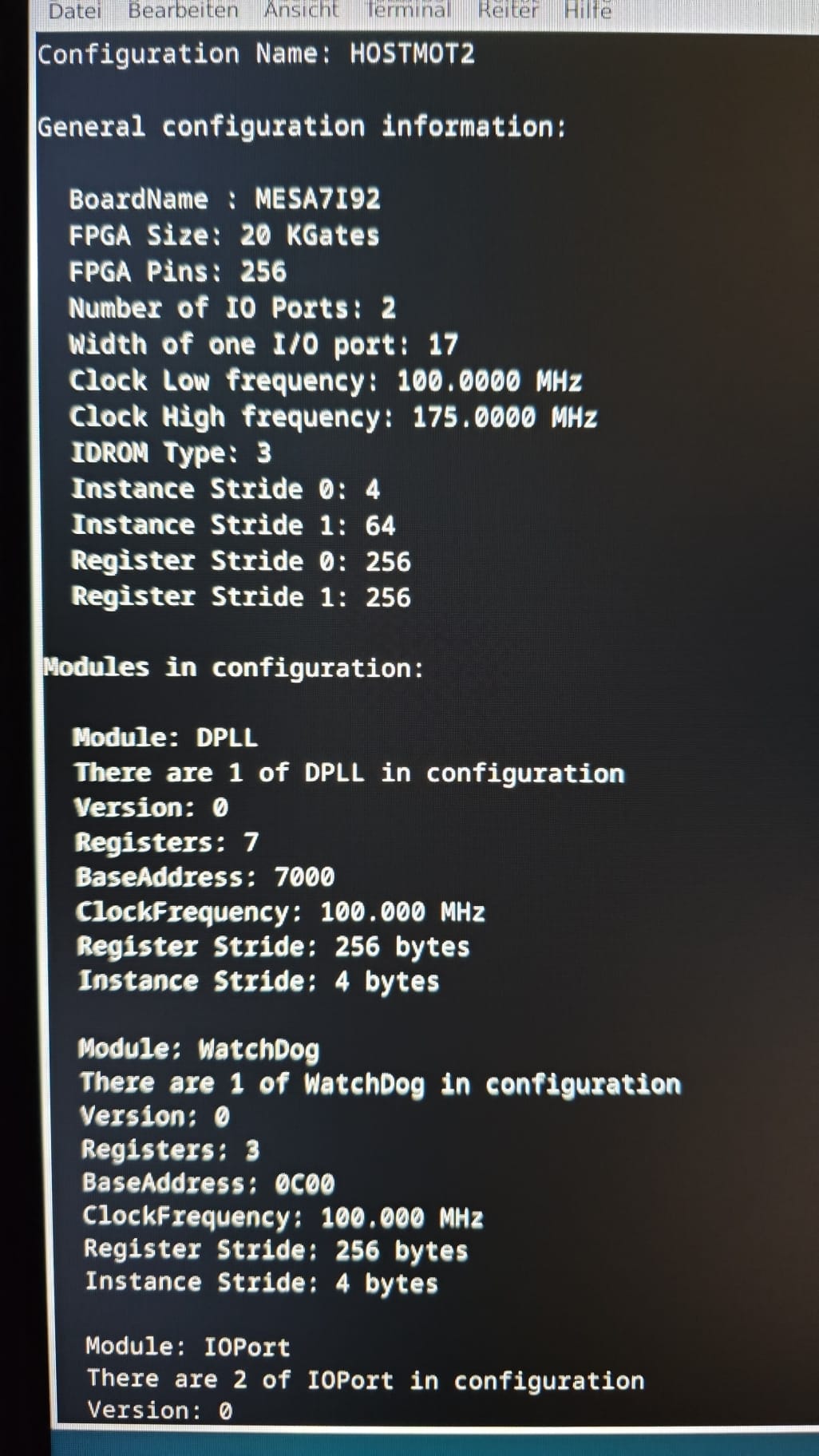

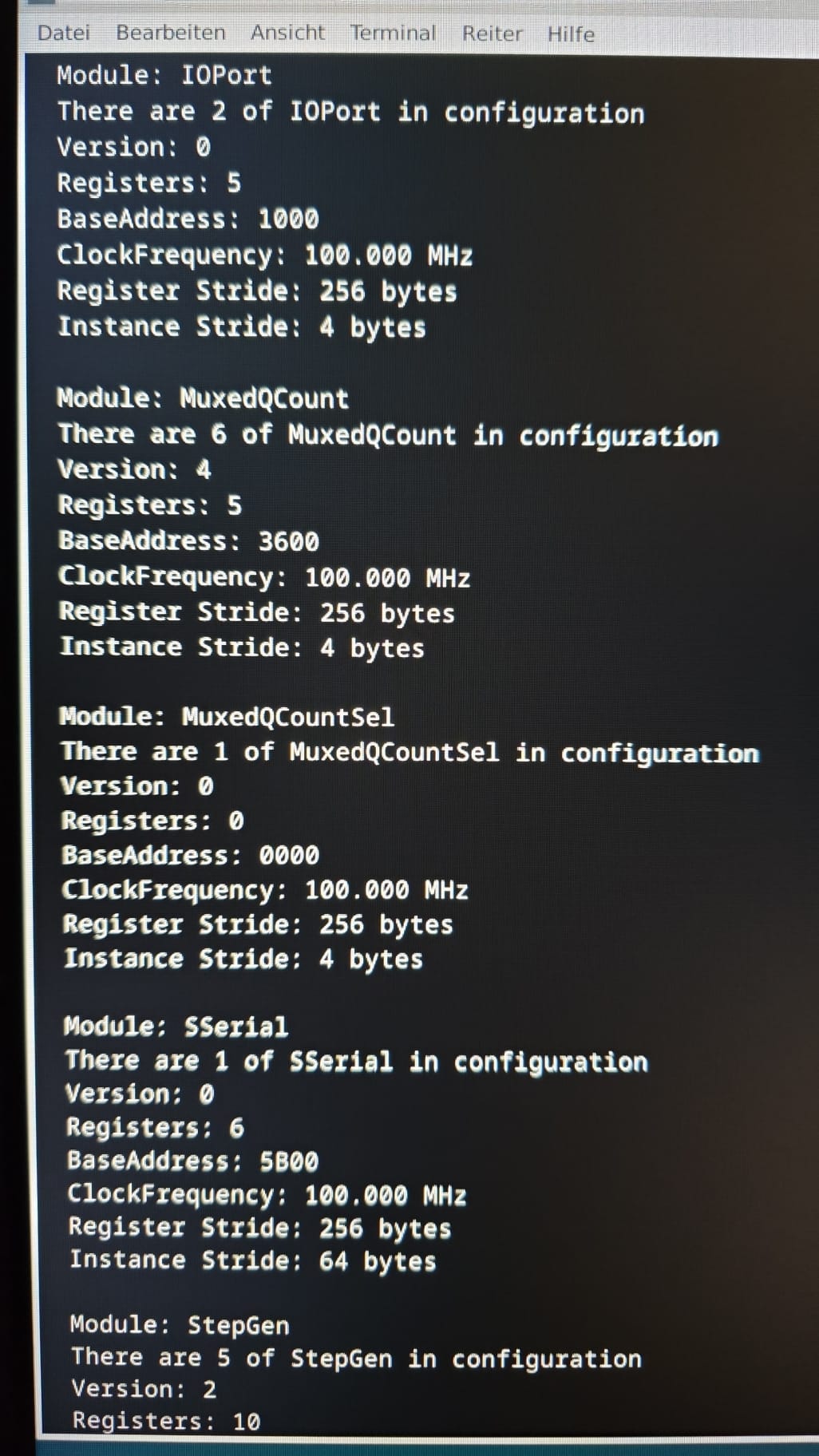

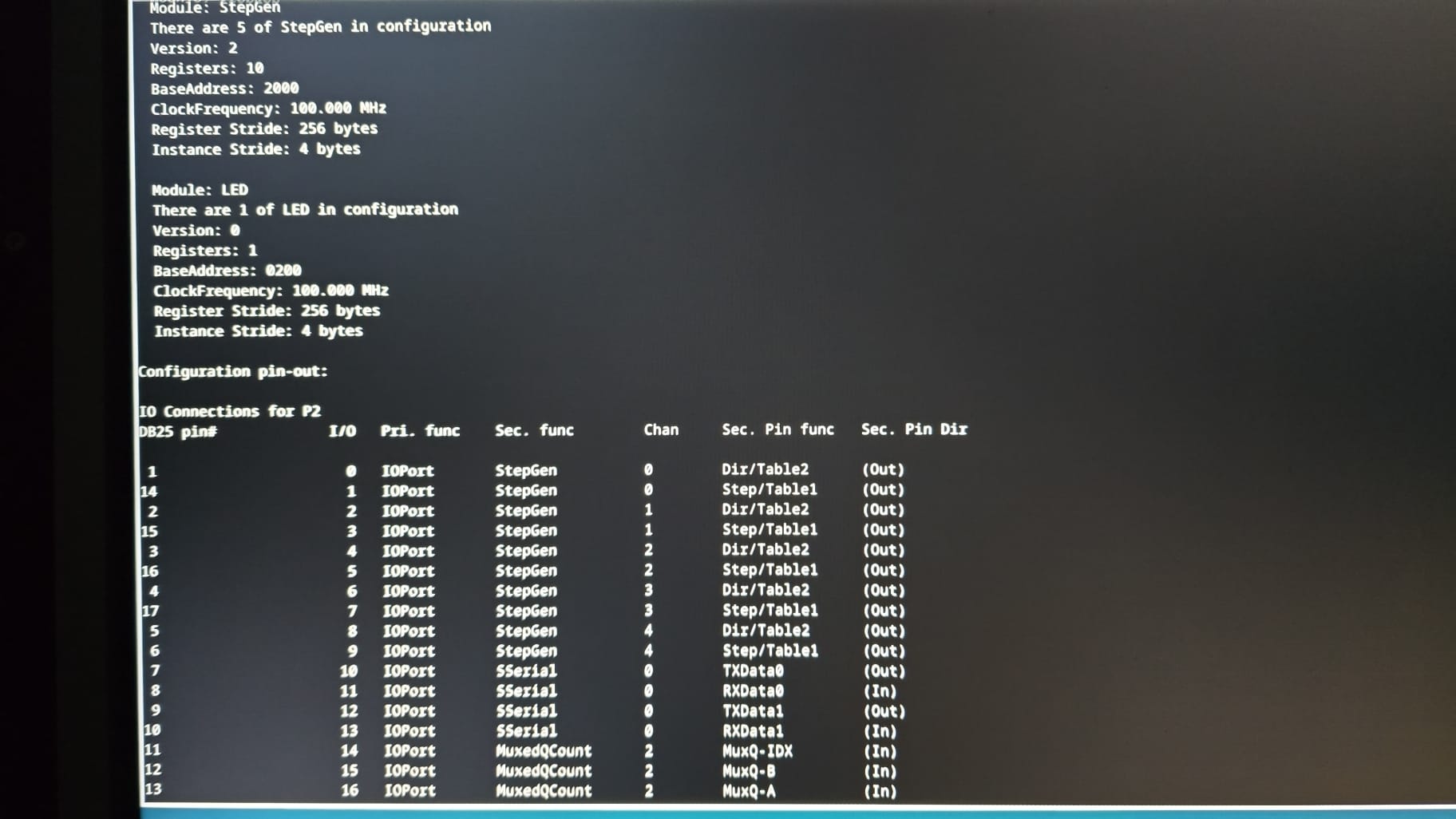

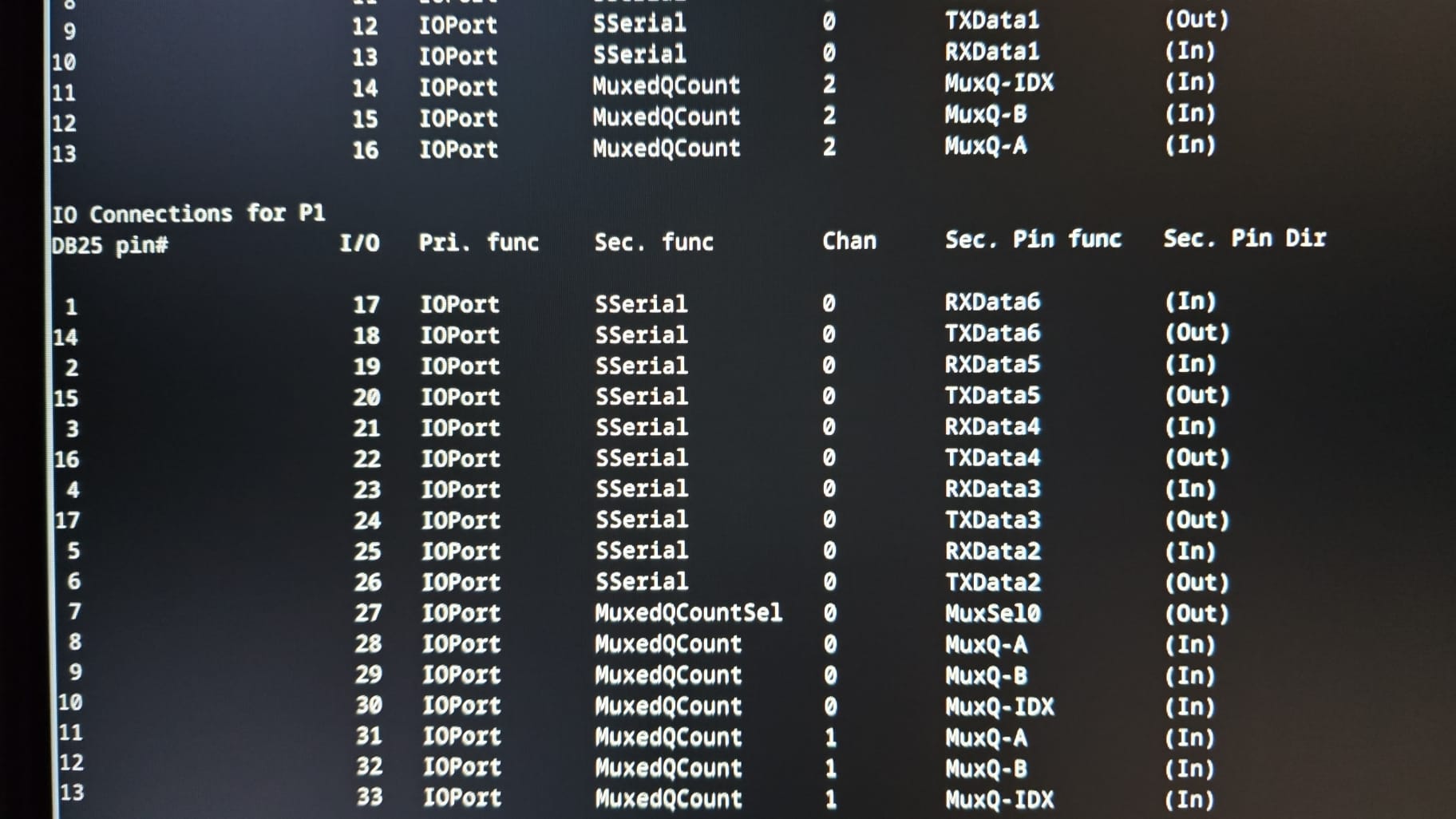

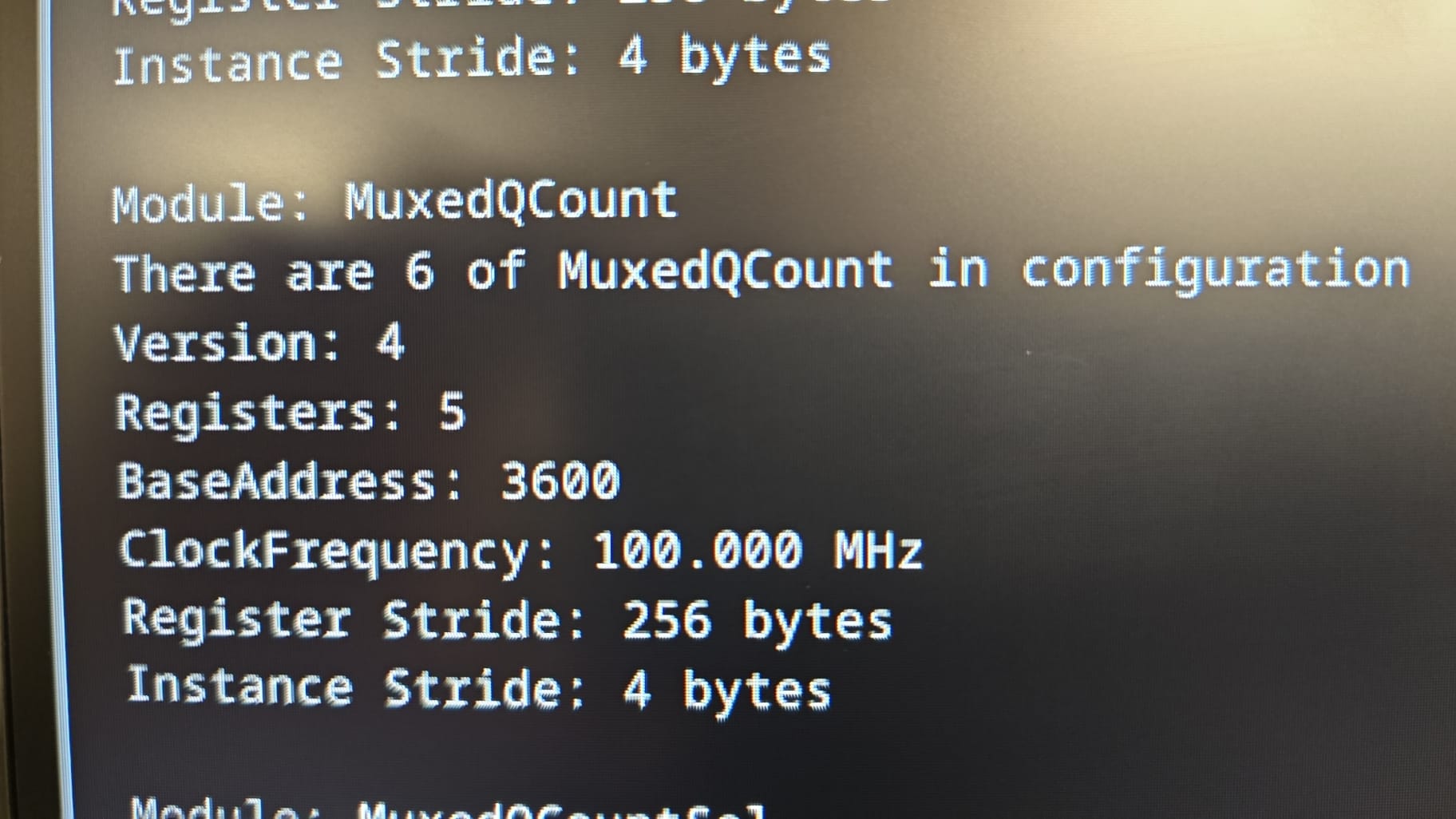

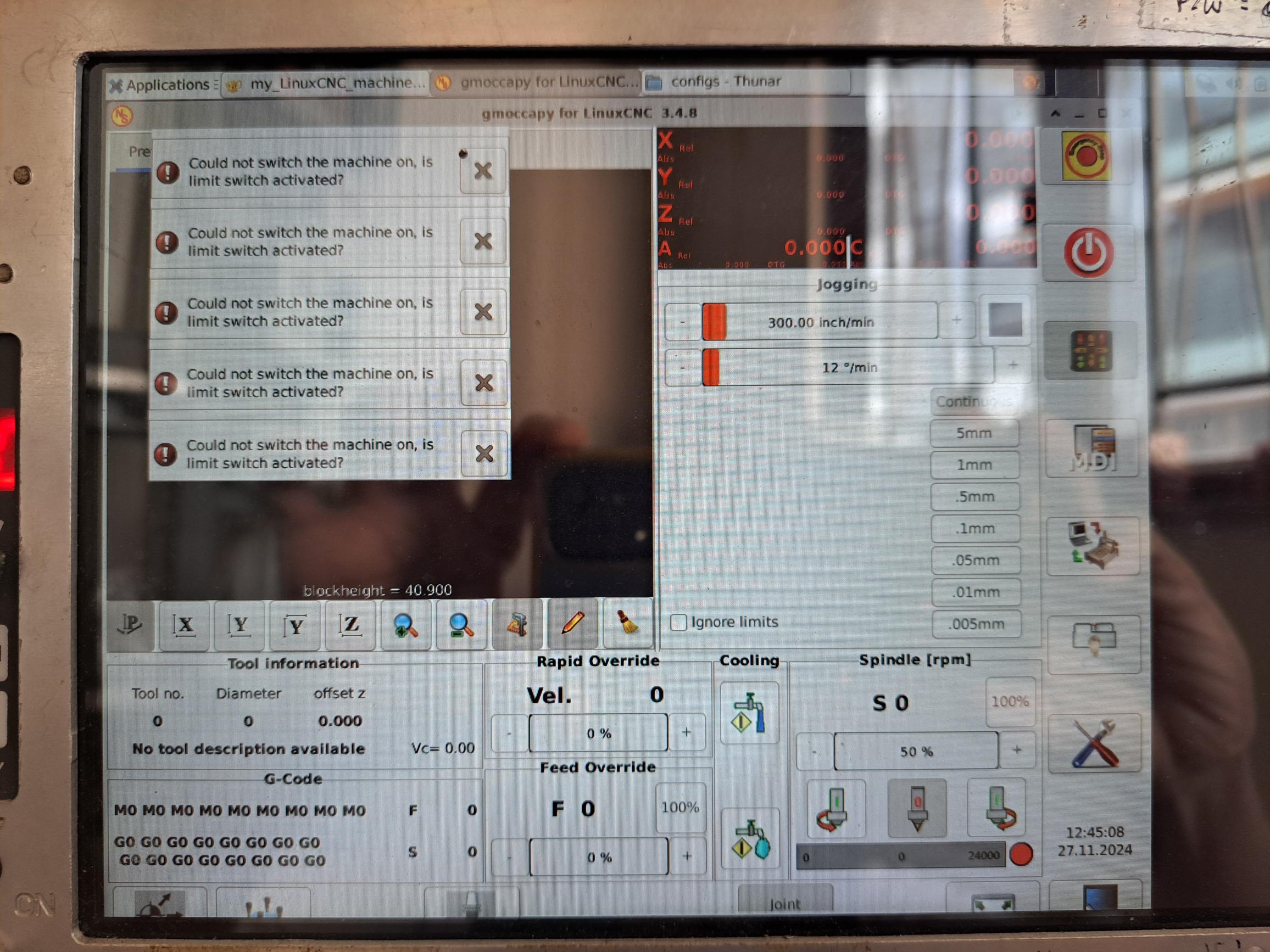

Des weiteren bin ich mir nicht sicher wie viele Encoder-Ausgänge ich wirklich habe, eigentlich hat die 7i76 nur einen und die 7i85 vier, wären also fünf, dann müsste ich meinen Eintrag auf "encoder.04" ändern (habe ich schon gemacht, aber funktioniert trotzdem nicht, liegt aber vielleicht an einer falscher Hal/INI). Ich habe ein paar Ausgaben von Mesaflash angehängt, womit ich ehrlich gesagt, nicht wirklich schlauer wurde:

Hier beim letzten, vermute ich, ist die Anzahl der Encoder angegeben, wie gesagt, Vermutung:

Ich hoffe das mir jemand bei diesem Problem helfen kann, ich komme selbst einfach nicht drauf.

Danke und Gruß

Olli