Search Results (Searched for: )

- nick_namsep

- nick_namsep

05 Jan 2025 12:41

Replied by nick_namsep on topic First time configuring ethercat

First time configuring ethercat

Category: EtherCAT

- mic

- mic

05 Jan 2025 12:31

Replied by mic on topic Ethercat, EL6751 and CANOpen

Ethercat, EL6751 and CANOpen

Category: EtherCAT

- Cant do this anymore bye all

05 Jan 2025 11:28

Replied by Cant do this anymore bye all on topic Arduino IO Expansion

Arduino IO Expansion

Category: Show Your Stuff

- Aciera

05 Jan 2025 10:47

- blazini36

- blazini36

05 Jan 2025 10:32

- tivoi

05 Jan 2025 09:33 - 05 Jan 2025 09:34

Replied by tivoi on topic Mini wannabe datron build

Mini wannabe datron build

Category: CNC Machines

- Hakan

- Hakan

05 Jan 2025 09:08

Replied by Hakan on topic First time configuring ethercat

First time configuring ethercat

Category: EtherCAT

- NTULINUX

05 Jan 2025 08:44

Replied by NTULINUX on topic Gentoo Image, Which Applications are in and Which are Out

Gentoo Image, Which Applications are in and Which are Out

Category: General LinuxCNC Questions

- timo

- timo

05 Jan 2025 08:35

Replied by timo on topic Stepper based machine some general questions

Stepper based machine some general questions

Category: General LinuxCNC Questions

- rodw

05 Jan 2025 08:09

- rodw

05 Jan 2025 08:06

- ihavenofish

- ihavenofish

05 Jan 2025 05:23

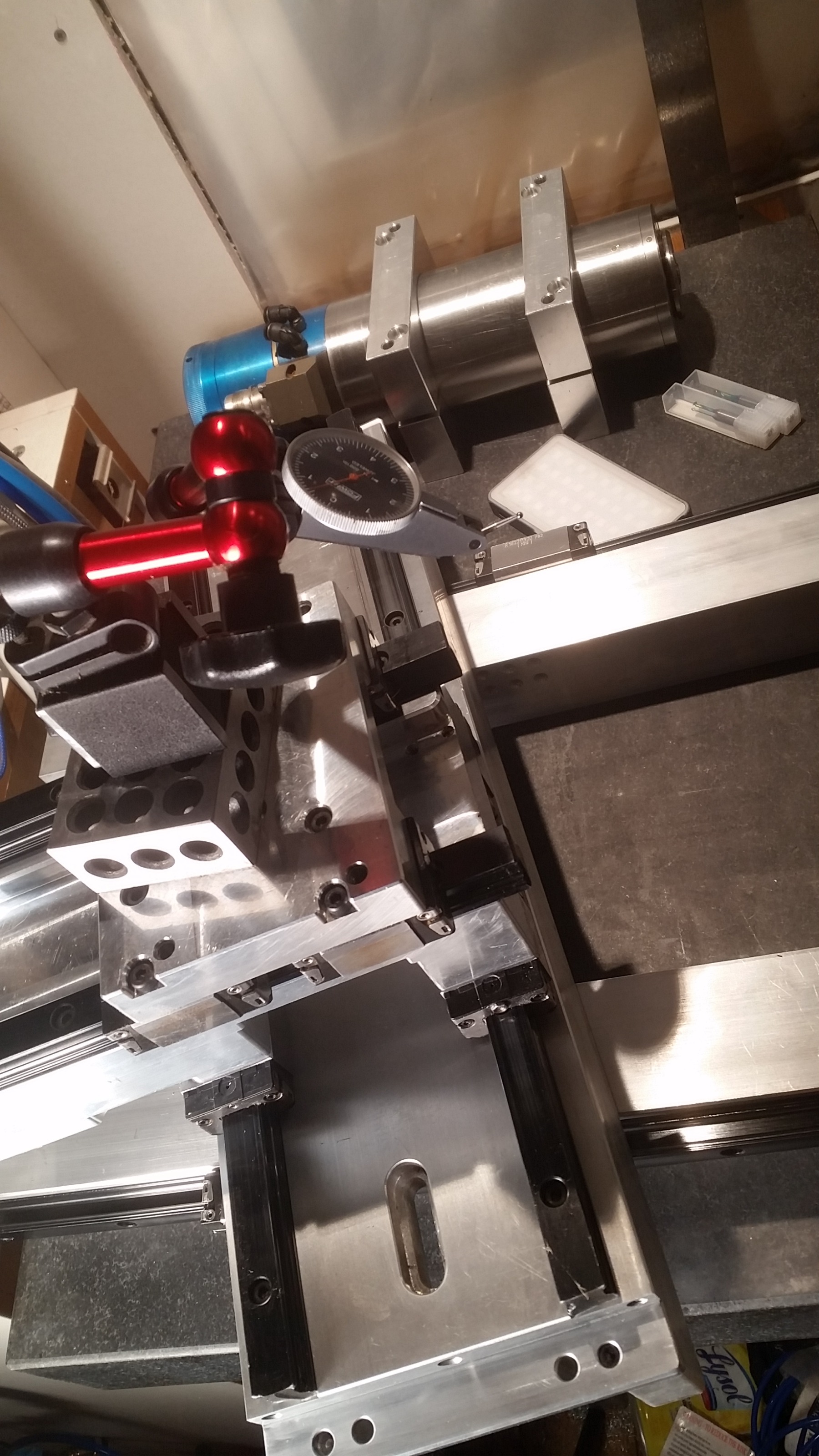

Replied by ihavenofish on topic Mini wannabe datron build

Mini wannabe datron build

Category: CNC Machines

- dschultz

- dschultz

05 Jan 2025 04:50

- dmalcolm

- dmalcolm

05 Jan 2025 02:24

STMBL V4.3 Setting smart serial node address was created by dmalcolm

STMBL V4.3 Setting smart serial node address

Category: General LinuxCNC Questions

- spumco

- spumco

05 Jan 2025 02:09

Replied by spumco on topic Mcode out of range, greater than 199 error

Mcode out of range, greater than 199 error

Category: G&M Codes

Time to create page: 0.457 seconds