Search Results (Searched for: )

- aikiaviator

- aikiaviator

24 Dec 2024 07:07

Replied by aikiaviator on topic To Probe Basic from Gmoccapy

To Probe Basic from Gmoccapy

Category: QtPyVCP

- beauxnez

- beauxnez

24 Dec 2024 06:30 - 24 Dec 2024 08:09

Replied by beauxnez on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Dave2024

24 Dec 2024 04:27 - 24 Dec 2024 04:41

Replied by Dave2024 on topic After homing move off of limit switch

After homing move off of limit switch

Category: Basic Configuration

- aikiaviator

- aikiaviator

24 Dec 2024 04:15

Replied by aikiaviator on topic To Probe Basic from Gmoccapy

To Probe Basic from Gmoccapy

Category: QtPyVCP

- Lcvette

24 Dec 2024 03:55 - 24 Dec 2024 03:57

Replied by Lcvette on topic To Probe Basic from Gmoccapy

To Probe Basic from Gmoccapy

Category: QtPyVCP

- aikiaviator

- aikiaviator

24 Dec 2024 03:50

Replied by aikiaviator on topic To Probe Basic from Gmoccapy

To Probe Basic from Gmoccapy

Category: QtPyVCP

- aikiaviator

- aikiaviator

24 Dec 2024 03:40

Replied by aikiaviator on topic To Probe Basic from Gmoccapy

To Probe Basic from Gmoccapy

Category: QtPyVCP

- Trihwangyudi1990

- Trihwangyudi1990

24 Dec 2024 03:24

Replied by Trihwangyudi1990 on topic ESP32/S2/S3 LinuxCNC Controller (6 axis hardware step gen), USB plug-and-play

ESP32/S2/S3 LinuxCNC Controller (6 axis hardware step gen), USB plug-and-play

Category: Computers and Hardware

- PCW

24 Dec 2024 02:56

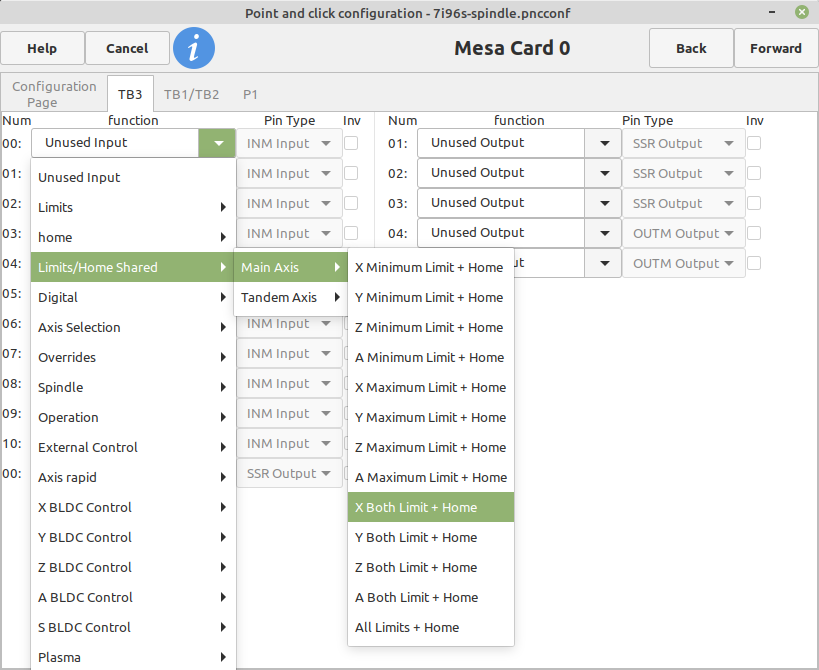

Replied by PCW on topic After homing move off of limit switch

After homing move off of limit switch

Category: Basic Configuration

- Dave2024

24 Dec 2024 01:57 - 24 Dec 2024 02:50

Replied by Dave2024 on topic After homing move off of limit switch

After homing move off of limit switch

Category: Basic Configuration

- PCW

24 Dec 2024 01:24

- gardenweazel

24 Dec 2024 01:10

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- Sternfox

- Sternfox

24 Dec 2024 01:09

- PCW

24 Dec 2024 00:54 - 24 Dec 2024 01:11

Replied by PCW on topic After homing move off of limit switch

After homing move off of limit switch

Category: Basic Configuration

- Dave2024

24 Dec 2024 00:42

Replied by Dave2024 on topic After homing move off of limit switch

After homing move off of limit switch

Category: Basic Configuration

Time to create page: 0.589 seconds