Search Results (Searched for: )

- tommylight

13 Aug 2024 00:53

Replied by tommylight on topic Joint Amplifier Fault on Non-Moving Axis

Joint Amplifier Fault on Non-Moving Axis

Category: Basic Configuration

- JamesHoward

- JamesHoward

13 Aug 2024 00:48

Replied by JamesHoward on topic ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

Category: Driver Boards

- Benb

12 Aug 2024 22:52

Replied by Benb on topic MCG Server Controller for 4th axis

MCG Server Controller for 4th axis

Category: Driver Boards

- cakeslob

- cakeslob

12 Aug 2024 22:40

- rodw

12 Aug 2024 21:23

Replied by rodw on topic Pi4b and Pi5 users - What should go in a 2.9.3 image

Pi4b and Pi5 users - What should go in a 2.9.3 image

Category: Installing LinuxCNC

- Mecanix

- Mecanix

12 Aug 2024 21:04

Replied by Mecanix on topic Y axis configuration

Y axis configuration

Category: General LinuxCNC Questions

- cakeslob

- cakeslob

12 Aug 2024 21:04

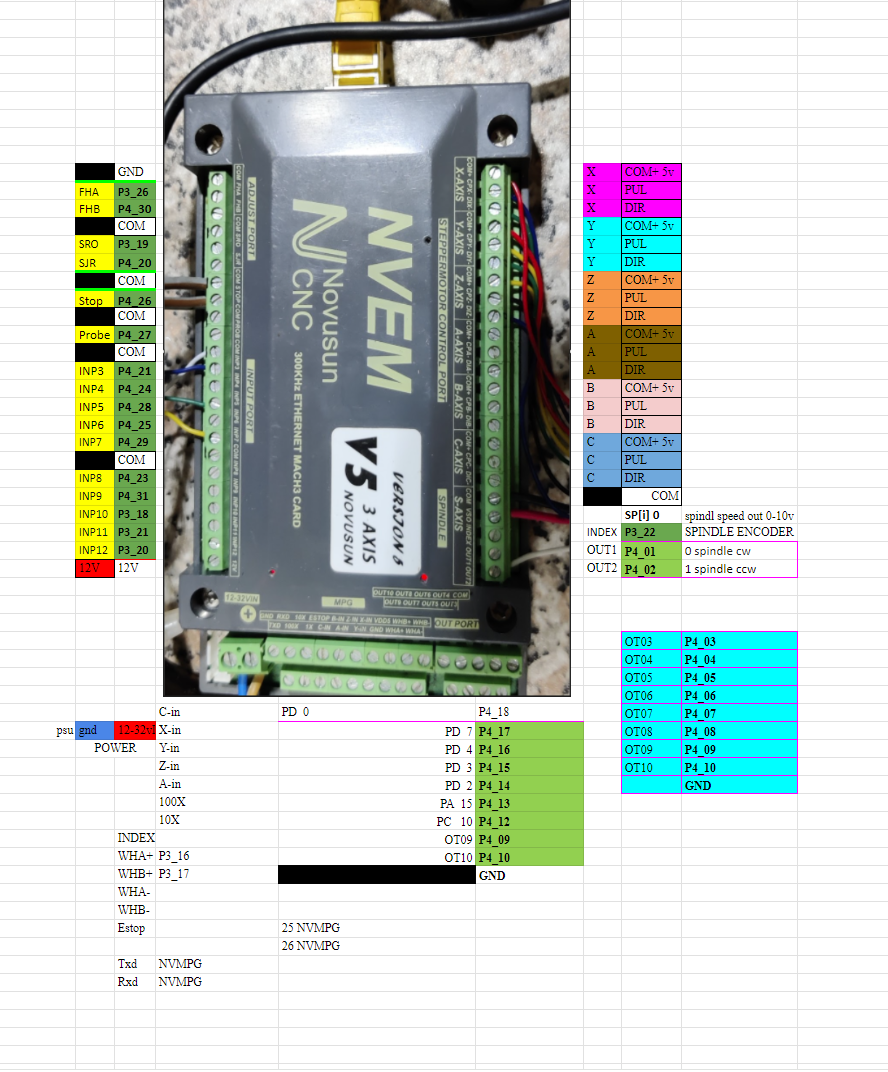

Replied by cakeslob on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Ismacr63

- Ismacr63

12 Aug 2024 20:56

Replied by Ismacr63 on topic Y axis configuration

Y axis configuration

Category: General LinuxCNC Questions

- cakeslob

- cakeslob

12 Aug 2024 20:56

Replied by cakeslob on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Mecanix

- Mecanix

12 Aug 2024 20:47

Replied by Mecanix on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- scotta

12 Aug 2024 20:38 - 12 Aug 2024 20:38

- Mecanix

- Mecanix

12 Aug 2024 20:34 - 12 Aug 2024 20:35

Replied by Mecanix on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- meister

- meister

12 Aug 2024 20:22

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- Limo

- Limo

12 Aug 2024 20:18

- AlessandroEmm

- AlessandroEmm

12 Aug 2024 20:11

Replied by AlessandroEmm on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

Time to create page: 0.537 seconds