Search Results (Searched for: )

- ruediger123

- ruediger123

17 Jan 2026 20:30

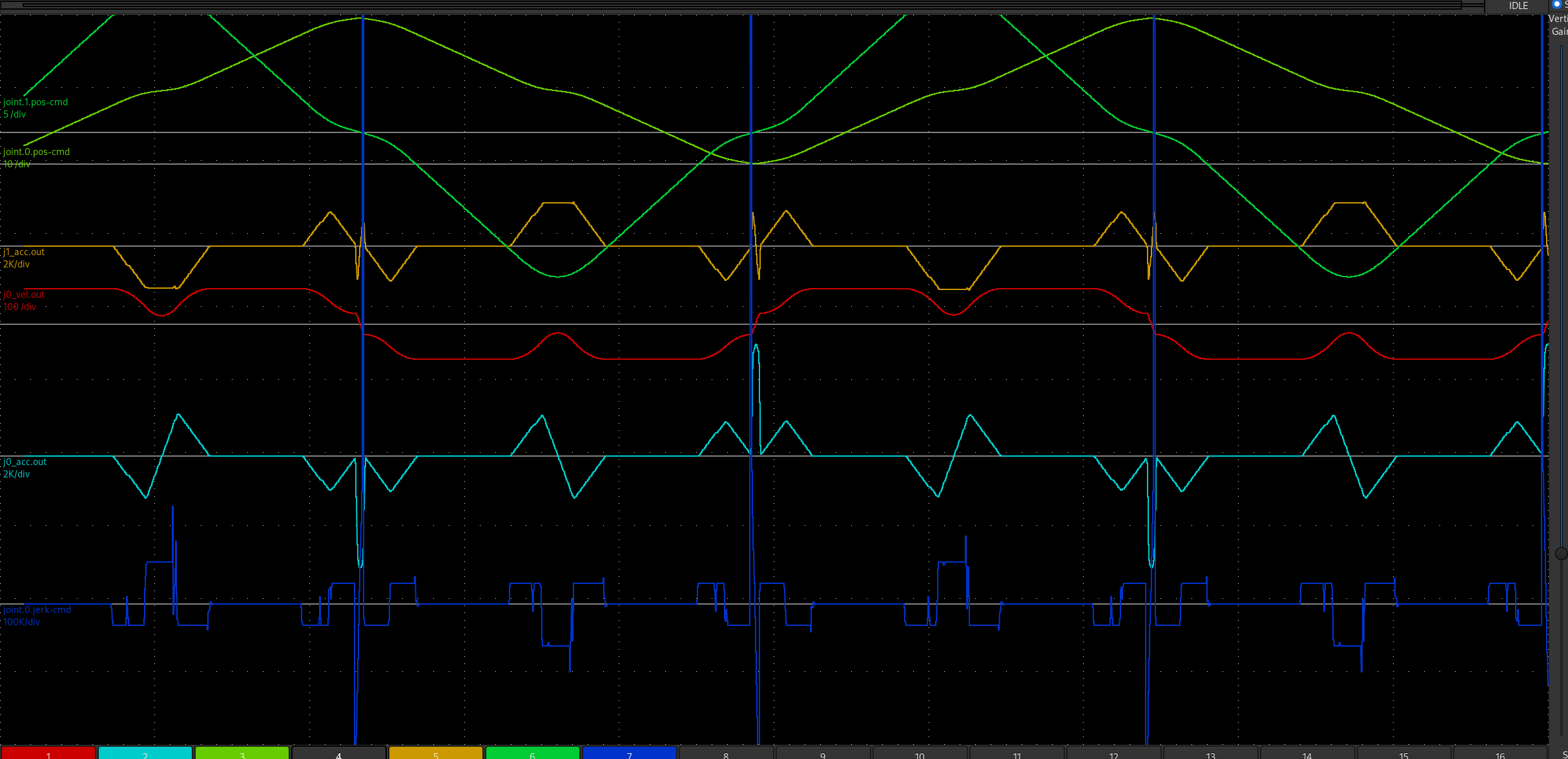

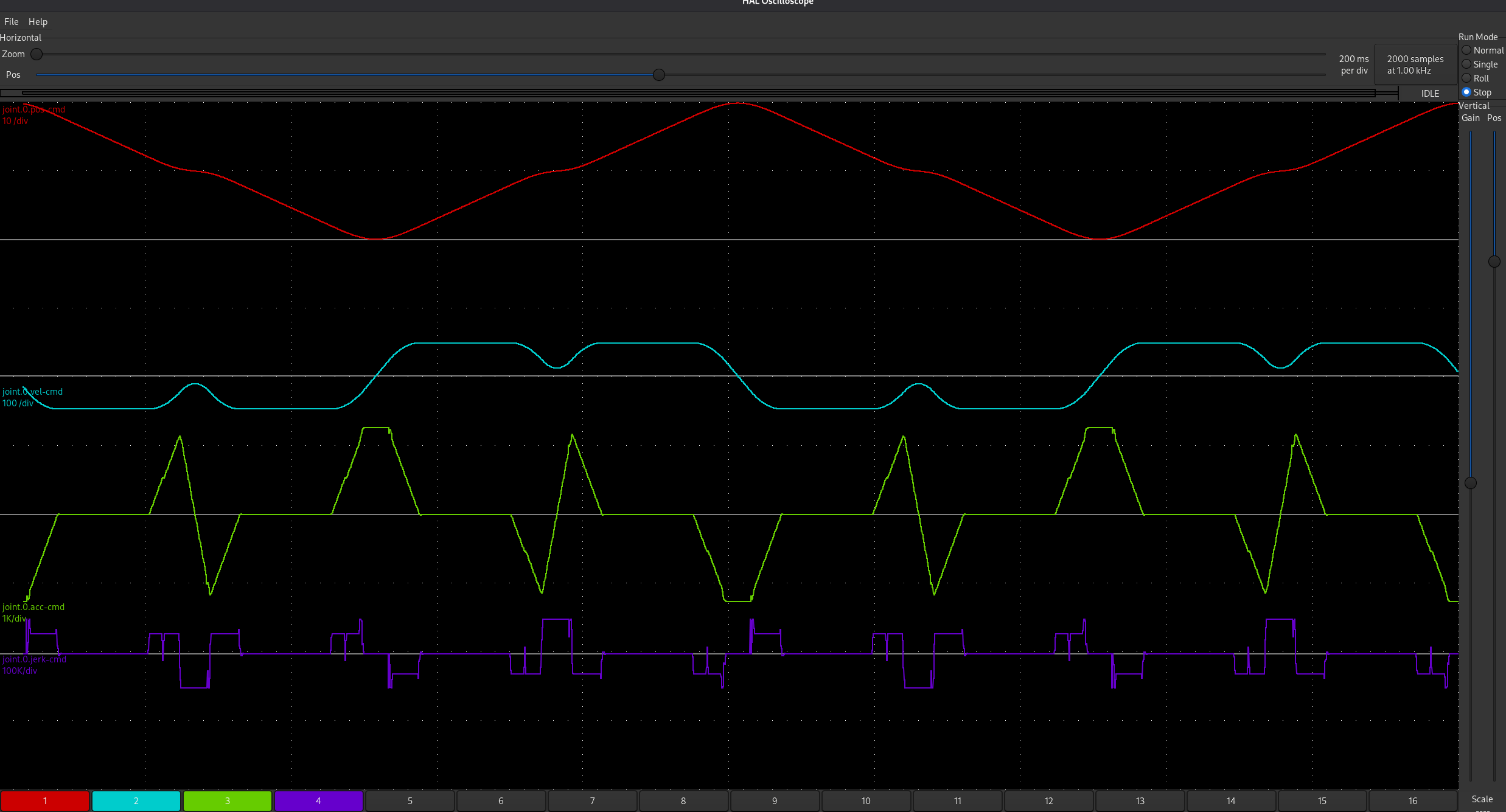

Replied by ruediger123 on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- advangrootel

- advangrootel

17 Jan 2026 20:12

need firmware for mesa 7i76eu+7i85+pwm was created by advangrootel

need firmware for mesa 7i76eu+7i85+pwm

Category: Driver Boards

- Lili

- Lili

17 Jan 2026 20:07

Replied by Lili on topic Single LC10E-600W Driver Not Responding

Single LC10E-600W Driver Not Responding

Category: EtherCAT

- reboots

- reboots

17 Jan 2026 18:10 - 17 Jan 2026 18:14

Replied by reboots on topic How do I lubricate correctly?

How do I lubricate correctly?

Category: Milling Machines

- bobwolf

- bobwolf

17 Jan 2026 16:42

- cmorley

- cmorley

17 Jan 2026 16:34

- cmorley

- cmorley

17 Jan 2026 15:39

- harindugamlath

- harindugamlath

17 Jan 2026 15:27

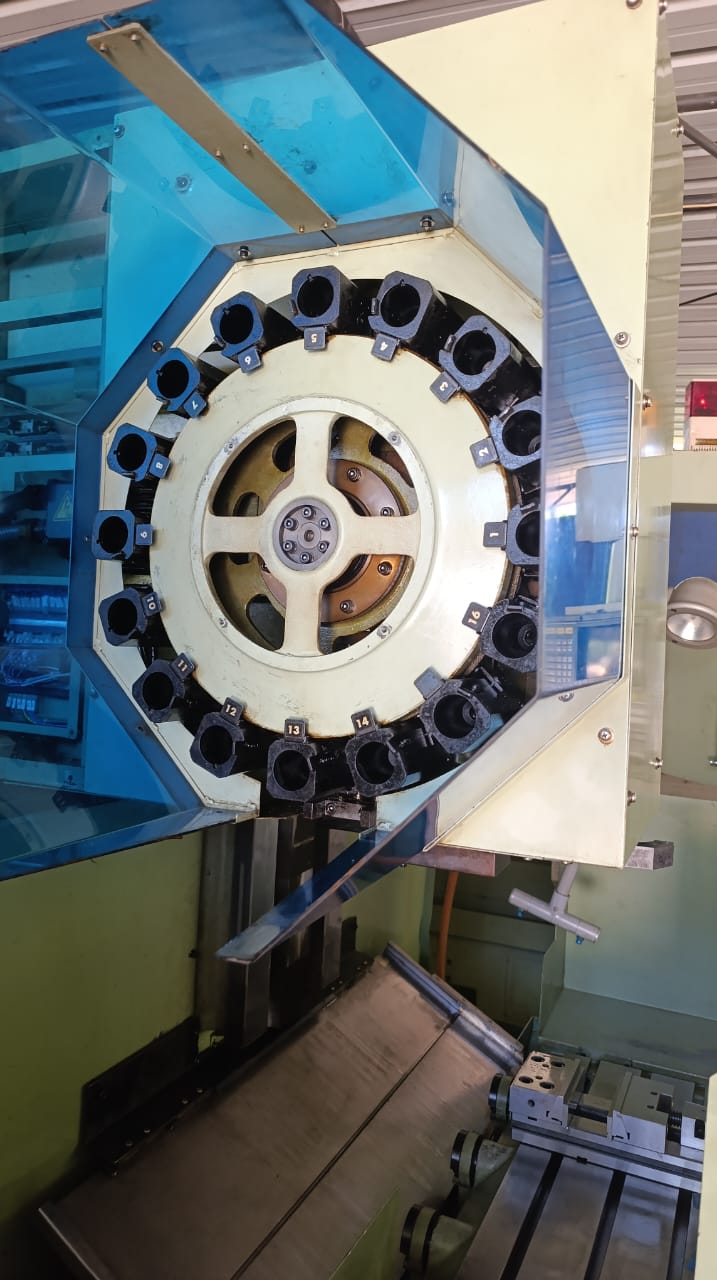

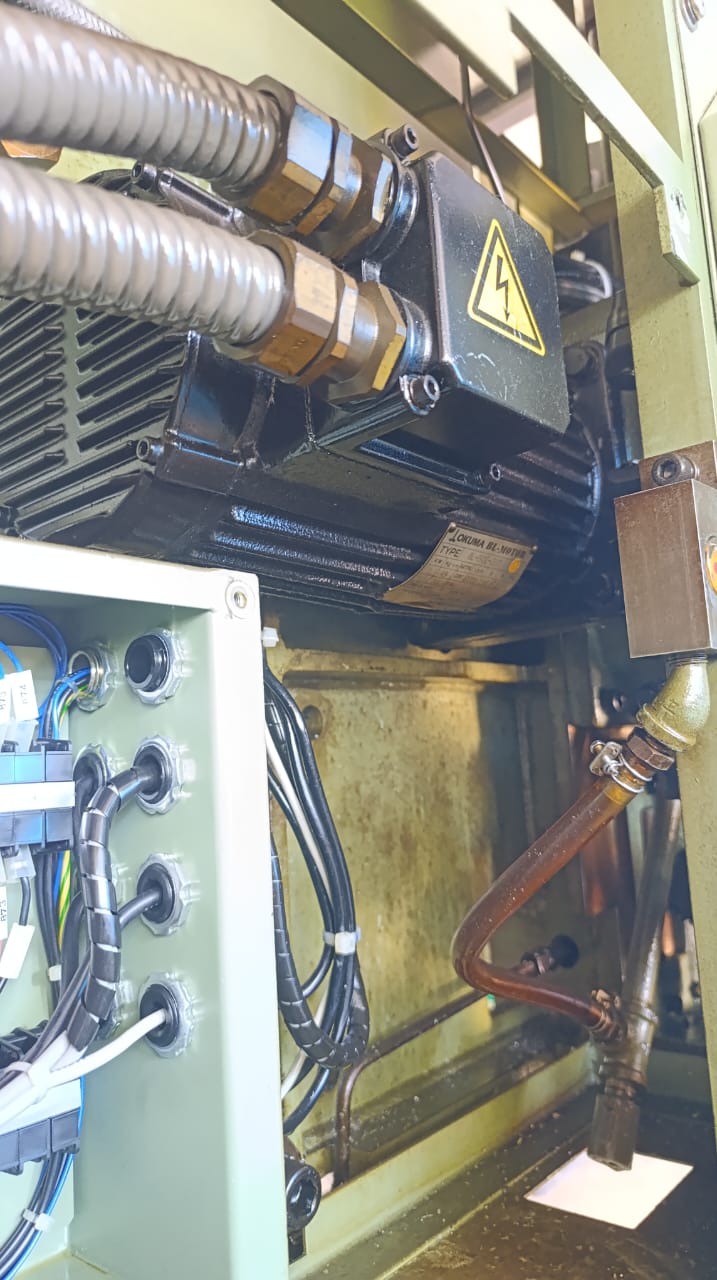

Servo Driven tool changer - How to set up was created by harindugamlath

Servo Driven tool changer - How to set up

Category: Advanced Configuration

- cmorley

- cmorley

17 Jan 2026 15:11

- grandixximo

17 Jan 2026 14:50 - 17 Jan 2026 16:01

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- amanker

- amanker

17 Jan 2026 13:53

Replied by amanker on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

- 3404gerber

- 3404gerber

17 Jan 2026 13:32

Replied by 3404gerber on topic Linuxcnc erste Schritte und erste Probleme, NVEM und Remora

Linuxcnc erste Schritte und erste Probleme, NVEM und Remora

Category: Deutsch

- tommylight

17 Jan 2026 12:52

- harindugamlath

- harindugamlath

17 Jan 2026 11:49

Replied by harindugamlath on topic How good is Ethercat motion control?

How good is Ethercat motion control?

Category: EtherCAT

- Aciera

17 Jan 2026 11:47

Replied by Aciera on topic Can my account and post history be deleted please

Can my account and post history be deleted please

Category: Forum Questions

Time to create page: 0.470 seconds