Search Results (Searched for: )

- sin-do-re

- sin-do-re

03 Jul 2024 21:55

- dg9mdr

- dg9mdr

03 Jul 2024 21:29

Replied by dg9mdr on topic Touchscreen mit Debian 12 und LCNC 2.9 nutzen?

Touchscreen mit Debian 12 und LCNC 2.9 nutzen?

Category: Deutsch

- ihavenofish

- ihavenofish

03 Jul 2024 19:59

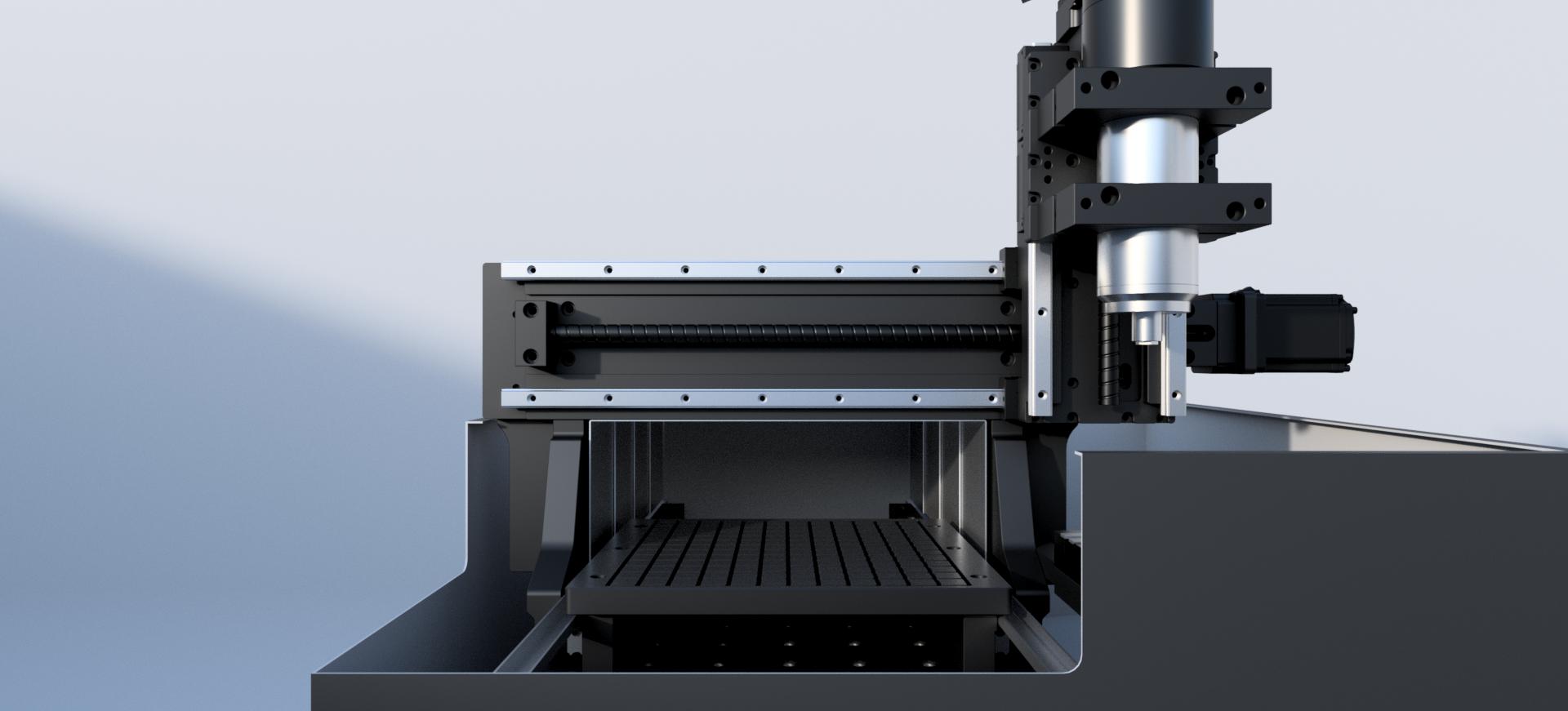

Replied by ihavenofish on topic Mini wannabe datron build

Mini wannabe datron build

Category: CNC Machines

- RMJ fabrication

- RMJ fabrication

03 Jul 2024 19:38

Replied by RMJ fabrication on topic qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

Category: Plasmac

- tomala89

- tomala89

03 Jul 2024 19:15

- meister

- meister

03 Jul 2024 15:54

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- seuchato

- seuchato

03 Jul 2024 15:31

Replied by seuchato on topic manual-toolchange-with-tool-length-switch sim fails mill upgraded to 2.9.2

manual-toolchange-with-tool-length-switch sim fails mill upgraded to 2.9.2

Category: AXIS

- hpmax

- hpmax

03 Jul 2024 15:17

Time to create page: 1.604 seconds