Search Results (Searched for: )

- amanker

- amanker

08 Jan 2026 18:43

Replied by amanker on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

- lorenzing

- lorenzing

08 Jan 2026 15:51 - 08 Jan 2026 15:55

- PHILCOAST

08 Jan 2026 15:43

Replied by PHILCOAST on topic RPi CM5 on Mesa Ethernet 7i95

RPi CM5 on Mesa Ethernet 7i95

Category: General LinuxCNC Questions

- nick.smith

- nick.smith

08 Jan 2026 15:20

Replied by nick.smith on topic Start PathPilot without a Mesa card connected

Start PathPilot without a Mesa card connected

Category: PathPilot

- scsmith1451

08 Jan 2026 13:28

Replied by scsmith1451 on topic No configuration pages for Y2 Axis

No configuration pages for Y2 Axis

Category: PnCConf Wizard

- akg1904

- akg1904

08 Jan 2026 10:30

Replied by akg1904 on topic Clarifying the Rot-point values

Clarifying the Rot-point values

Category: Advanced Configuration

- SOLD

- SOLD

08 Jan 2026 10:24

Replied by SOLD on topic 7i92M + 7i76 add PWM+PktUART

7i92M + 7i76 add PWM+PktUART

Category: Driver Boards

- Stvn

- Stvn

08 Jan 2026 09:59

- Aciera

08 Jan 2026 09:40

Replied by Aciera on topic Clarifying the Rot-point values

Clarifying the Rot-point values

Category: Advanced Configuration

- akg1904

- akg1904

08 Jan 2026 08:22

Clarifying the Rot-point values was created by akg1904

Clarifying the Rot-point values

Category: Advanced Configuration

- soehlrich

- soehlrich

08 Jan 2026 08:10

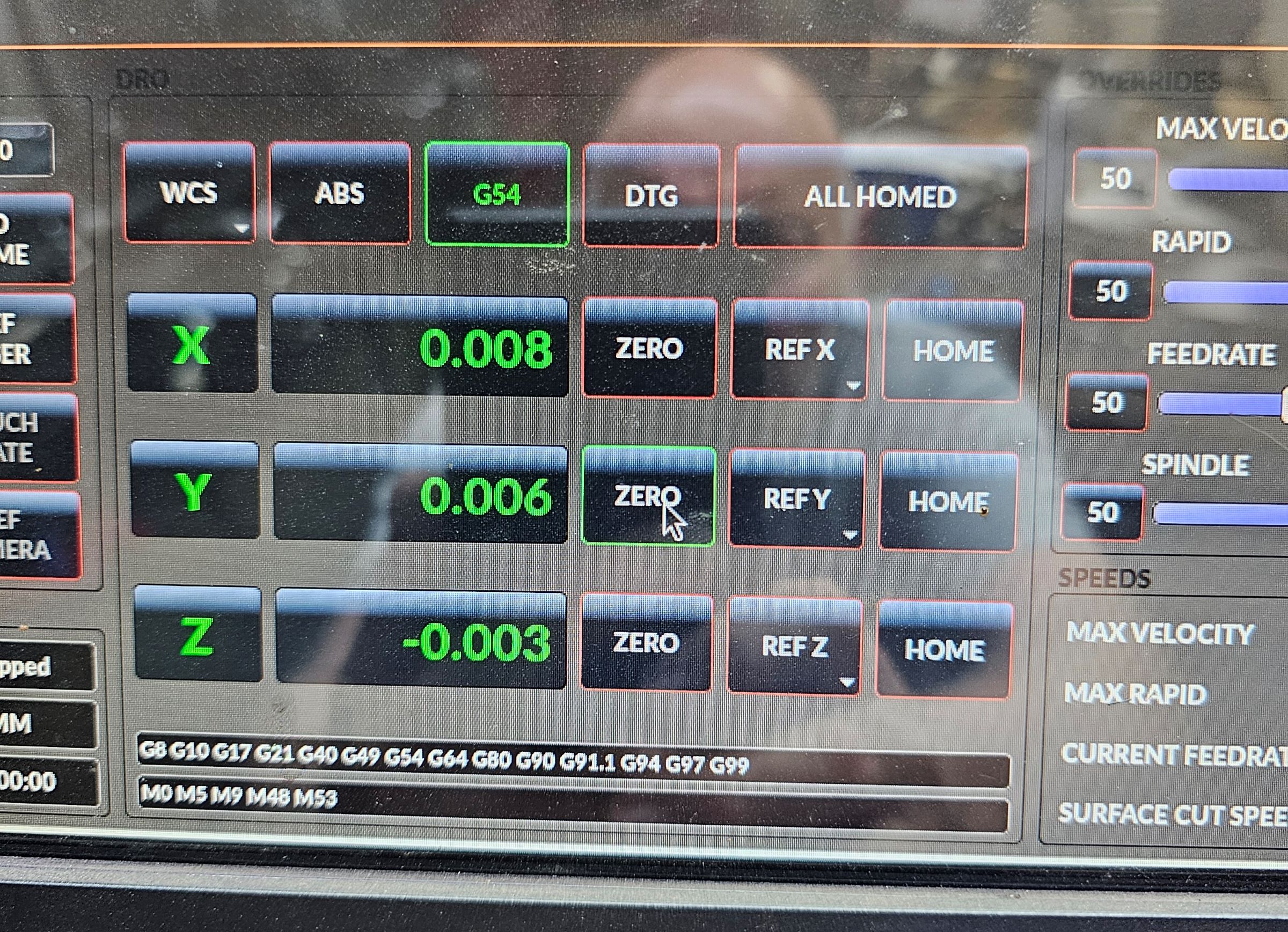

Replied by soehlrich on topic Qtdragon_hd Zero button not zeroing

Qtdragon_hd Zero button not zeroing

Category: General LinuxCNC Questions

- grandixximo

08 Jan 2026 06:30 - 08 Jan 2026 06:48

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- rodw

08 Jan 2026 05:57

Replied by rodw on topic New and Working RTAI debs for 2.9

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- cmorley

- cmorley

08 Jan 2026 05:50

Replied by cmorley on topic Qtdragon_hd Zero button not zeroing

Qtdragon_hd Zero button not zeroing

Category: General LinuxCNC Questions

- soehlrich

- soehlrich

08 Jan 2026 05:32

Replied by soehlrich on topic Qtdragon_hd Zero button not zeroing

Qtdragon_hd Zero button not zeroing

Category: General LinuxCNC Questions

Time to create page: 0.403 seconds