Search Results (Searched for: )

- dann1324

- dann1324

26 Dec 2025 22:57

- tommylight

26 Dec 2025 22:53

Replied by tommylight on topic Mesa 6i25 not working?

Mesa 6i25 not working?

Category: Driver Boards

- zippoffs

26 Dec 2025 22:47

Replied by zippoffs on topic DIY CNC Mill - Random Limit Switch Errors

DIY CNC Mill - Random Limit Switch Errors

Category: Milling Machines

- PCW

26 Dec 2025 22:46

- Surmetall

26 Dec 2025 22:39

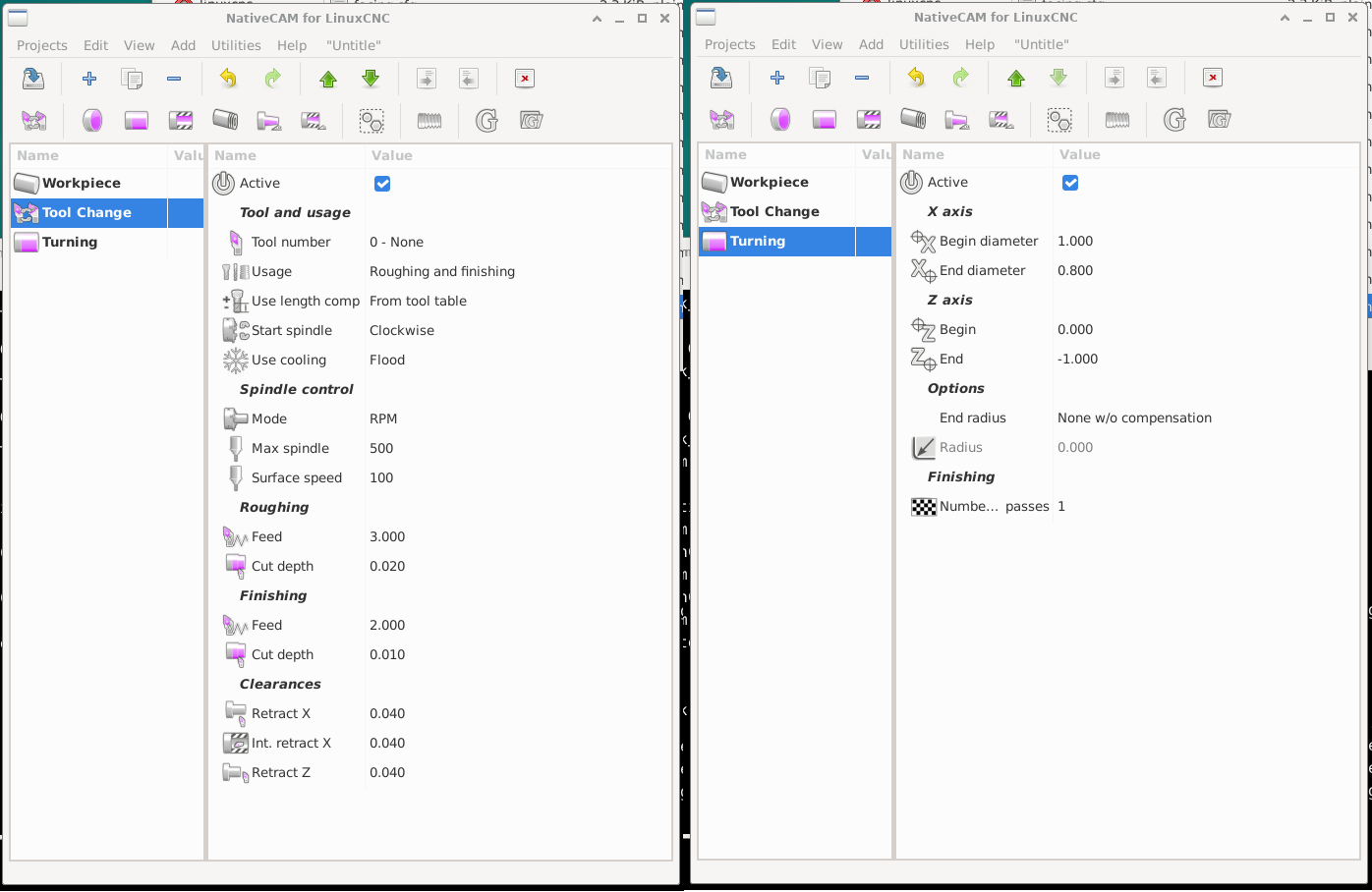

Replied by Surmetall on topic LatheEasyStep – experimental QtVCP macro for step-by-step lathe programming

LatheEasyStep – experimental QtVCP macro for step-by-step lathe programming

Category: Qtvcp

- sorokin_pro

26 Dec 2025 22:20

Replied by sorokin_pro on topic Mesa 6i25 not working?

Mesa 6i25 not working?

Category: Driver Boards

- PCW

26 Dec 2025 22:16

- sorokin_pro

26 Dec 2025 22:02

Replied by sorokin_pro on topic Mesa 6i25 not working?

Mesa 6i25 not working?

Category: Driver Boards

- tlightus

- tlightus

26 Dec 2025 21:51

Replied by tlightus on topic calling subroutine from G54, G55, G56, but it acts weird

calling subroutine from G54, G55, G56, but it acts weird

Category: O Codes (subroutines) and NGCGUI

- PCW

26 Dec 2025 21:49

- sorokin_pro

26 Dec 2025 21:44 - 26 Dec 2025 21:45

Replied by sorokin_pro on topic Mesa 6i25 not working?

Mesa 6i25 not working?

Category: Driver Boards

- Routercnc

- Routercnc

26 Dec 2025 21:24 - 27 Dec 2025 11:23

- PCW

26 Dec 2025 19:48

- tommylight

26 Dec 2025 19:43

Replied by tommylight on topic No speed control on xhc-wb04b-6 pendant on 3 axis router

No speed control on xhc-wb04b-6 pendant on 3 axis router

Category: Basic Configuration

- aDm1N

26 Dec 2025 19:41

Time to create page: 0.403 seconds