Search Results (Searched for: )

- Hakan

- Hakan

25 Dec 2025 11:05

Replied by Hakan on topic Ver 2.9.4 iso clean install Trouble when disabling EOE

Ver 2.9.4 iso clean install Trouble when disabling EOE

Category: EtherCAT

- automata

- automata

25 Dec 2025 10:21

Replied by automata on topic Ver 2.9.4 iso clean install Trouble when disabling EOE

Ver 2.9.4 iso clean install Trouble when disabling EOE

Category: EtherCAT

- grandixximo

25 Dec 2025 09:46 - 25 Dec 2025 10:08

Replied by grandixximo on topic Ethercat random jitter fix

Ethercat random jitter fix

Category: EtherCAT

- Hakan

- Hakan

25 Dec 2025 09:44

Replied by Hakan on topic Ver 2.9.4 iso clean install Trouble when disabling EOE

Ver 2.9.4 iso clean install Trouble when disabling EOE

Category: EtherCAT

- tar_san

- tar_san

25 Dec 2025 09:09

Replied by tar_san on topic Ver 2.9.4 iso clean install Trouble when disabling EOE

Ver 2.9.4 iso clean install Trouble when disabling EOE

Category: EtherCAT

- Hakan

- Hakan

25 Dec 2025 08:48

- grandixximo

25 Dec 2025 07:37 - 25 Dec 2025 12:44

- NWE

25 Dec 2025 05:20 - 25 Dec 2025 05:33

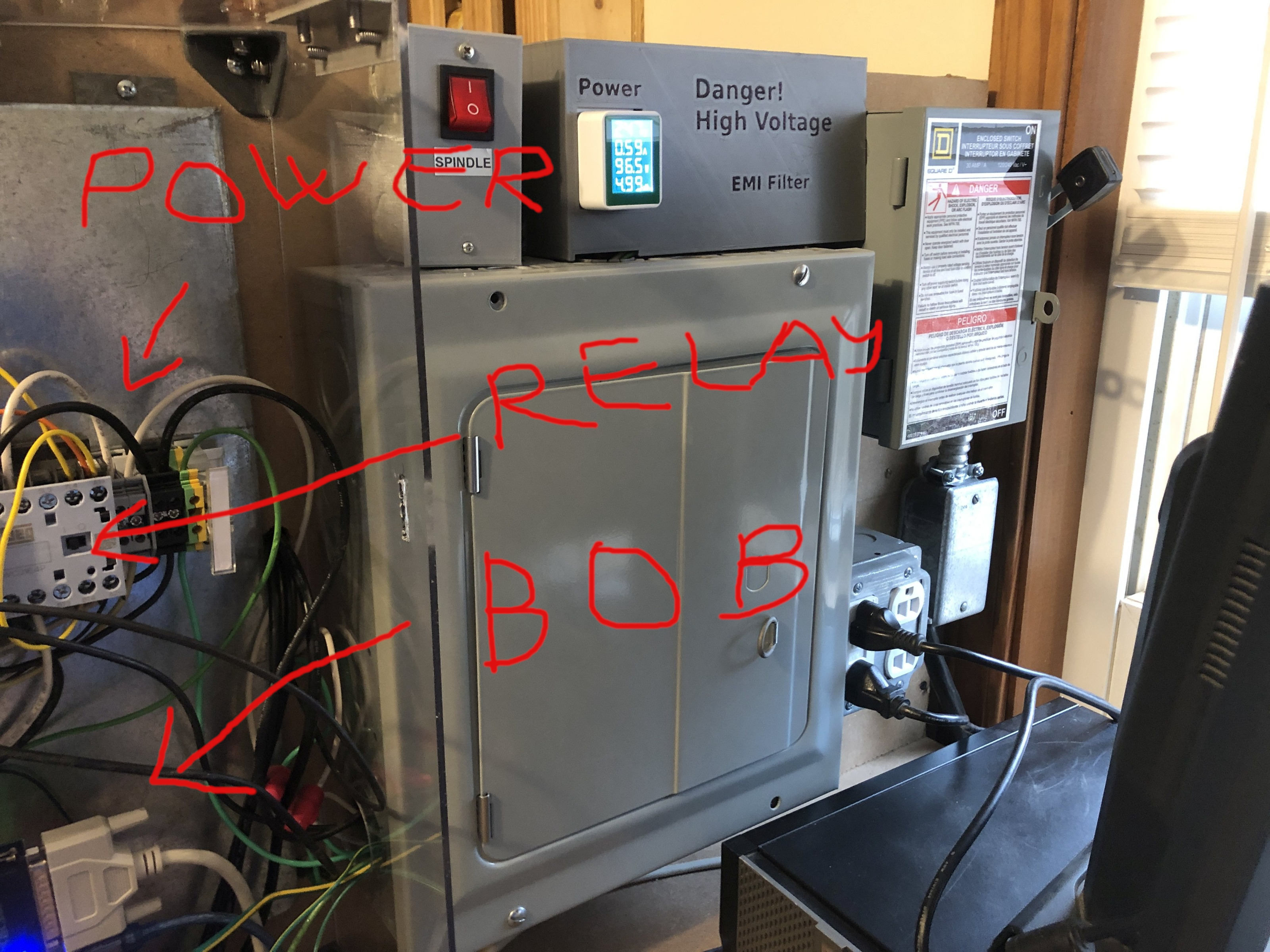

Replied by NWE on topic DIY CNC Mill - Random Limit Switch Errors

DIY CNC Mill - Random Limit Switch Errors

Category: Milling Machines

- NWE

25 Dec 2025 05:10 - 25 Dec 2025 05:11

Replied by NWE on topic DIY CNC Mill - Random Limit Switch Errors

DIY CNC Mill - Random Limit Switch Errors

Category: Milling Machines

- Bernardo

- Bernardo

25 Dec 2025 05:09

Replied by Bernardo on topic Custom HOME_SEARCH_VEL

Custom HOME_SEARCH_VEL

Category: Advanced Configuration

- tommylight

25 Dec 2025 05:02

Replied by tommylight on topic DIY CNC Mill - Random Limit Switch Errors

DIY CNC Mill - Random Limit Switch Errors

Category: Milling Machines

- NWE

25 Dec 2025 04:17

- snowgoer540

25 Dec 2025 04:03

Replied by snowgoer540 on topic Ohmic Probe + Material Height Feature Request

Ohmic Probe + Material Height Feature Request

Category: Plasmac

- NWE

25 Dec 2025 03:54

Replied by NWE on topic DIY CNC Mill - Random Limit Switch Errors

DIY CNC Mill - Random Limit Switch Errors

Category: Milling Machines

- NWE

25 Dec 2025 03:32 - 25 Dec 2025 03:42

Replied by NWE on topic DIY CNC Mill - Random Limit Switch Errors

DIY CNC Mill - Random Limit Switch Errors

Category: Milling Machines

Time to create page: 0.266 seconds