Search Results (Searched for: )

- robh

- robh

08 Mar 2025 20:48

Replied by robh on topic Joint Error After large rotary move

Joint Error After large rotary move

Category: General LinuxCNC Questions

- jst

- jst

08 Mar 2025 20:45

Replied by jst on topic Mitsubishi Meldas Control and Motors

Mitsubishi Meldas Control and Motors

Category: Milling Machines

- meister

- meister

08 Mar 2025 19:45

Replied by meister on topic How to Control a PWM Gripper

How to Control a PWM Gripper

Category: G&M Codes

- rodw

08 Mar 2025 19:25

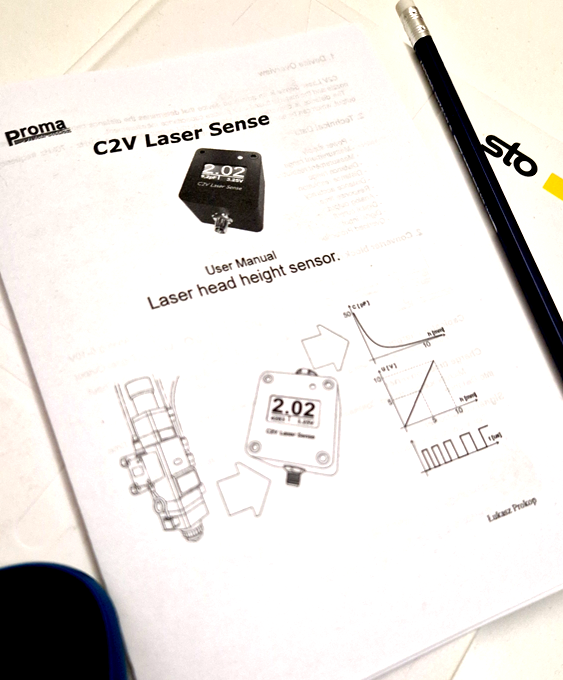

Replied by rodw on topic Laser Head Height Sensor – Looking for a Beta Tester

Laser Head Height Sensor – Looking for a Beta Tester

Category: Plasma & Laser

- robocidalmaniac

08 Mar 2025 19:17

Replied by robocidalmaniac on topic How to Control a PWM Gripper

How to Control a PWM Gripper

Category: G&M Codes

- jtrantow

- jtrantow

08 Mar 2025 18:40 - 08 Mar 2025 18:47

Replied by jtrantow on topic Rigid Tapping - VFD and needed encoder ppm

Rigid Tapping - VFD and needed encoder ppm

Category: Milling Machines

- PCW

08 Mar 2025 17:52 - 08 Mar 2025 17:53

Replied by PCW on topic 7i95t pin and firmware files with Stepgens and Inputs 5Axis BoB

7i95t pin and firmware files with Stepgens and Inputs 5Axis BoB

Category: Driver Boards

- cmorley

- cmorley

08 Mar 2025 17:01

- prokopcio

08 Mar 2025 17:01

Replied by prokopcio on topic Laser Head Height Sensor – Looking for a Beta Tester

Laser Head Height Sensor – Looking for a Beta Tester

Category: Plasma & Laser

- Nathan40

- Nathan40

08 Mar 2025 16:32 - 08 Mar 2025 16:34

Replied by Nathan40 on topic 7i95t pin and firmware files with Stepgens and Inputs 5Axis BoB

7i95t pin and firmware files with Stepgens and Inputs 5Axis BoB

Category: Driver Boards

- andypugh

08 Mar 2025 15:36

Replied by andypugh on topic Cheap Amazon touchscreen monitor

Cheap Amazon touchscreen monitor

Category: Computers and Hardware

- esmurf

- esmurf

08 Mar 2025 15:23

Replied by esmurf on topic ethercat driver crashes linux kernel

ethercat driver crashes linux kernel

Category: EtherCAT

- Murphy

- Murphy

08 Mar 2025 15:21 - 08 Mar 2025 15:23

Cheap Amazon touchscreen monitor was created by Murphy

Cheap Amazon touchscreen monitor

Category: Computers and Hardware

- PCW

08 Mar 2025 15:19

- jtrantow

- jtrantow

08 Mar 2025 15:08

Replied by jtrantow on topic Lathe spindle index only?

Lathe spindle index only?

Category: Basic Configuration

Time to create page: 0.271 seconds