Search Results (Searched for: estop_latch)

- tuxcnc

- tuxcnc

25 Mar 2025 18:52

Replied by tuxcnc on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- rodw

23 Feb 2025 07:36

- tommylight

23 Feb 2025 00:29

- rodw

23 Feb 2025 00:05

- MTTI

17 Feb 2025 08:16

Replied by MTTI on topic New and Working RTAI debs for 2.9

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- tommylight

14 Feb 2025 19:37

Replied by tommylight on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- rodw

16 Jan 2025 07:56 - 16 Jan 2025 07:57

Replied by rodw on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- notJamesLee

- notJamesLee

16 Jan 2025 04:06

Replied by notJamesLee on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- notJamesLee

- notJamesLee

15 Jan 2025 06:10 - 15 Jan 2025 16:50

Replied by notJamesLee on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- rodw

15 Jan 2025 03:00

Replied by rodw on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- Benb

29 Dec 2024 04:18

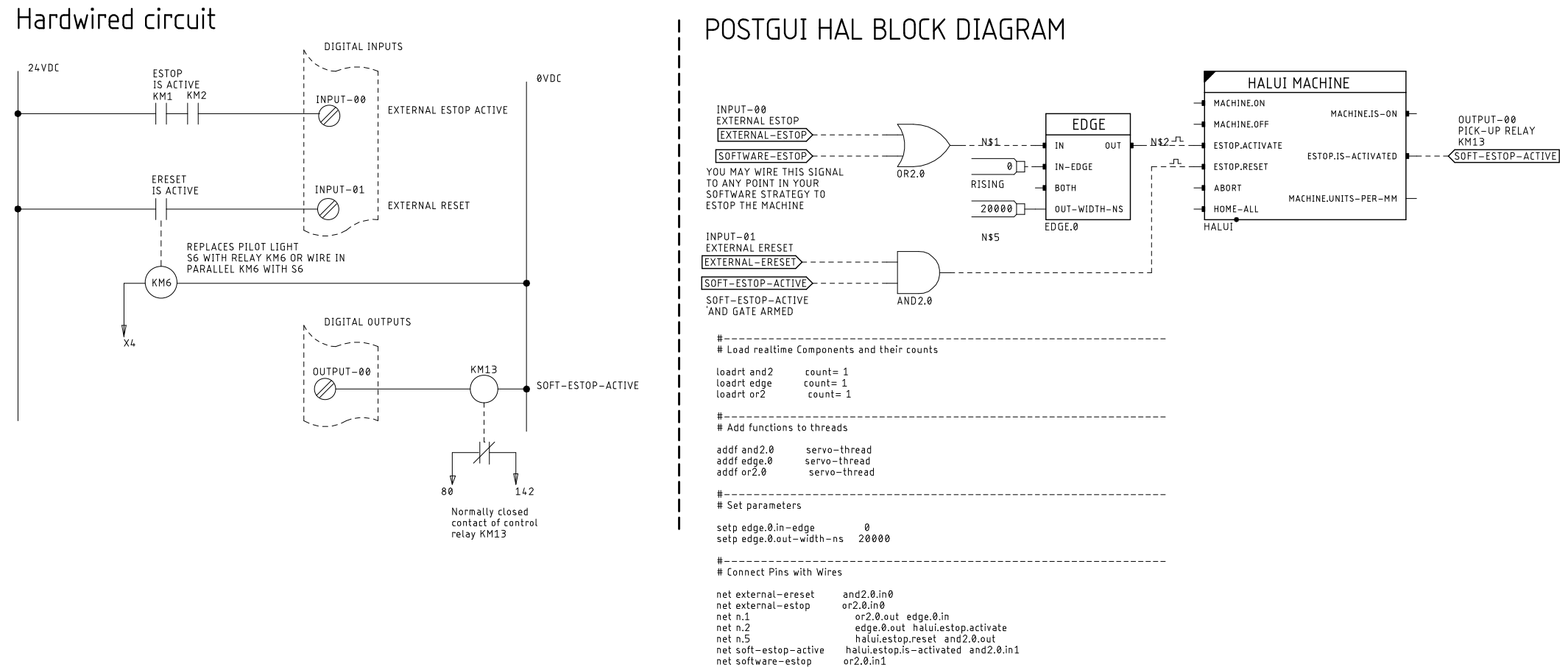

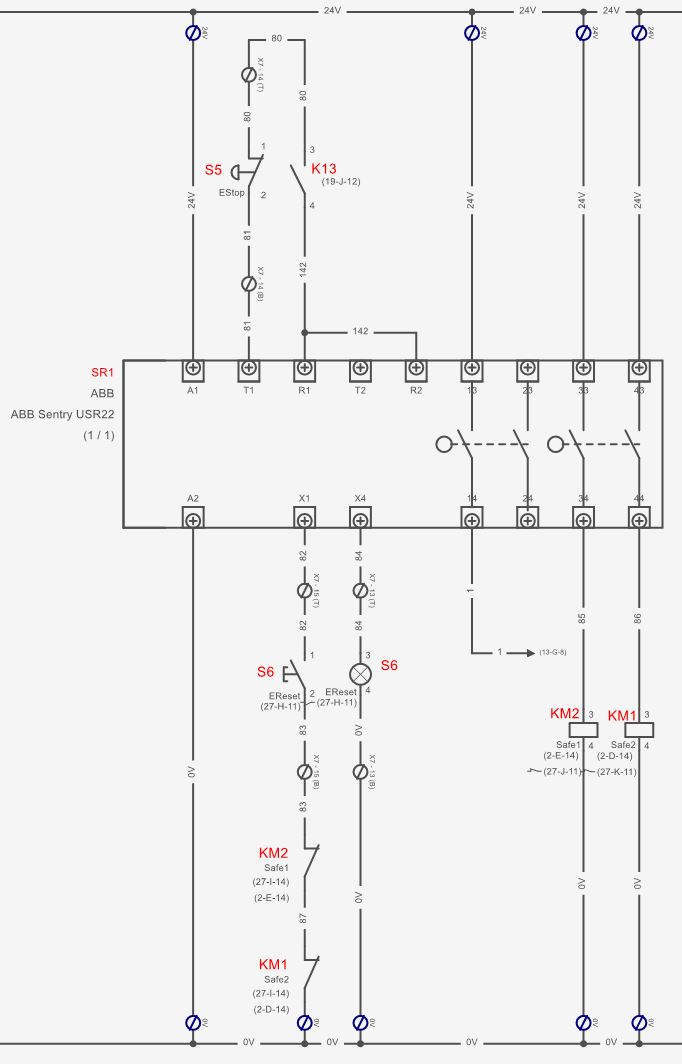

Replied by Benb on topic Physical safety relay and software estop latch working together?

Physical safety relay and software estop latch working together?

Category: HAL

- thomaseg

- thomaseg

28 Dec 2024 09:19

Replied by thomaseg on topic Physical safety relay and software estop latch working together?

Physical safety relay and software estop latch working together?

Category: HAL

- Benb

27 Dec 2024 01:10

Replied by Benb on topic Physical safety relay and software estop latch working together?

Physical safety relay and software estop latch working together?

Category: HAL

- rodw

26 Dec 2024 05:22

Replied by rodw on topic Physical safety relay and software estop latch working together?

Physical safety relay and software estop latch working together?

Category: HAL

- thomaseg

- thomaseg

25 Dec 2024 21:44 - 25 Dec 2024 21:48

Physical safety relay and software estop latch working together? was created by thomaseg

Physical safety relay and software estop latch working together?

Category: HAL

Time to create page: 1.016 seconds