Search Results (Searched for: 7i76e)

- PCW

20 Aug 2024 16:16

Replied by PCW on topic qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

Category: Plasmac

- RMJ fabrication

- RMJ fabrication

20 Aug 2024 15:39

Replied by RMJ fabrication on topic qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

Category: Plasmac

- acondit

- acondit

20 Aug 2024 15:36

Replied by acondit on topic Converting a 7i76e config to 7c81/7i76 pair

Converting a 7i76e config to 7c81/7i76 pair

Category: General LinuxCNC Questions

- PCW

20 Aug 2024 15:18

Replied by PCW on topic Converting a 7i76e config to 7c81/7i76 pair

Converting a 7i76e config to 7c81/7i76 pair

Category: General LinuxCNC Questions

- acondit

- acondit

20 Aug 2024 14:03

Replied by acondit on topic Converting a 7i76e config to 7c81/7i76 pair

Converting a 7i76e config to 7c81/7i76 pair

Category: General LinuxCNC Questions

- PCW

20 Aug 2024 02:48

Replied by PCW on topic Converting a 7i76e config to 7c81/7i76 pair

Converting a 7i76e config to 7c81/7i76 pair

Category: General LinuxCNC Questions

- acondit

- acondit

20 Aug 2024 01:44 - 20 Aug 2024 01:47

Replied by acondit on topic Converting a 7i76e config to 7c81/7i76 pair

Converting a 7i76e config to 7c81/7i76 pair

Category: General LinuxCNC Questions

- CNCFred

18 Aug 2024 19:15

Replied by CNCFred on topic Plasmac2QTplasma gives error not a Plasmac configuration /solved

Plasmac2QTplasma gives error not a Plasmac configuration /solved

Category: Plasmac

- PCW

18 Aug 2024 17:57

Replied by PCW on topic Getting an error on starting a machine

Getting an error on starting a machine

Category: General LinuxCNC Questions

- PCW

18 Aug 2024 16:15

Replied by PCW on topic Getting an error on starting a machine

Getting an error on starting a machine

Category: General LinuxCNC Questions

- PCW

18 Aug 2024 15:20

Replied by PCW on topic Getting an error on starting a machine

Getting an error on starting a machine

Category: General LinuxCNC Questions

- PCW

18 Aug 2024 14:44

Replied by PCW on topic Getting an error on starting a machine

Getting an error on starting a machine

Category: General LinuxCNC Questions

- PCW

18 Aug 2024 13:39

Replied by PCW on topic Getting an error on starting a machine

Getting an error on starting a machine

Category: General LinuxCNC Questions

- __Tom

- __Tom

18 Aug 2024 13:01

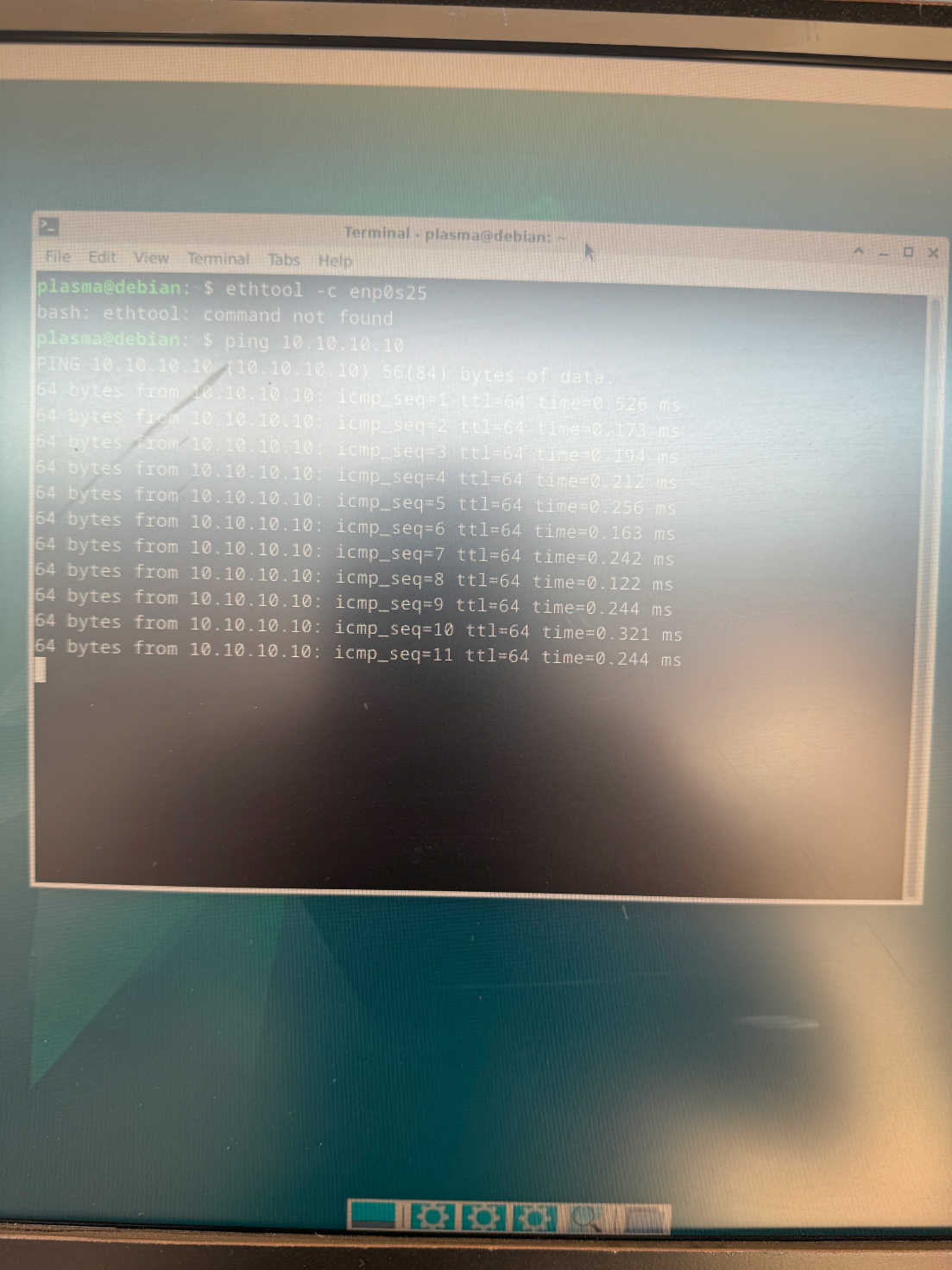

Getting an error on starting a machine was created by __Tom

Getting an error on starting a machine

Category: General LinuxCNC Questions

- PCW

16 Aug 2024 18:27

Replied by PCW on topic qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

Category: Plasmac

Time to create page: 1.038 seconds