Search Results (Searched for: stepper spindle)

- DarkPhoinix

- DarkPhoinix

15 May 2025 14:01 - 15 May 2025 14:04

Replied by DarkPhoinix on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Hakan

- Hakan

08 May 2025 06:05

- koch777

- koch777

06 May 2025 02:18

Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2) was created by koch777

Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2)

Category: Driver Boards

- IB_CnC

- IB_CnC

04 May 2025 12:22

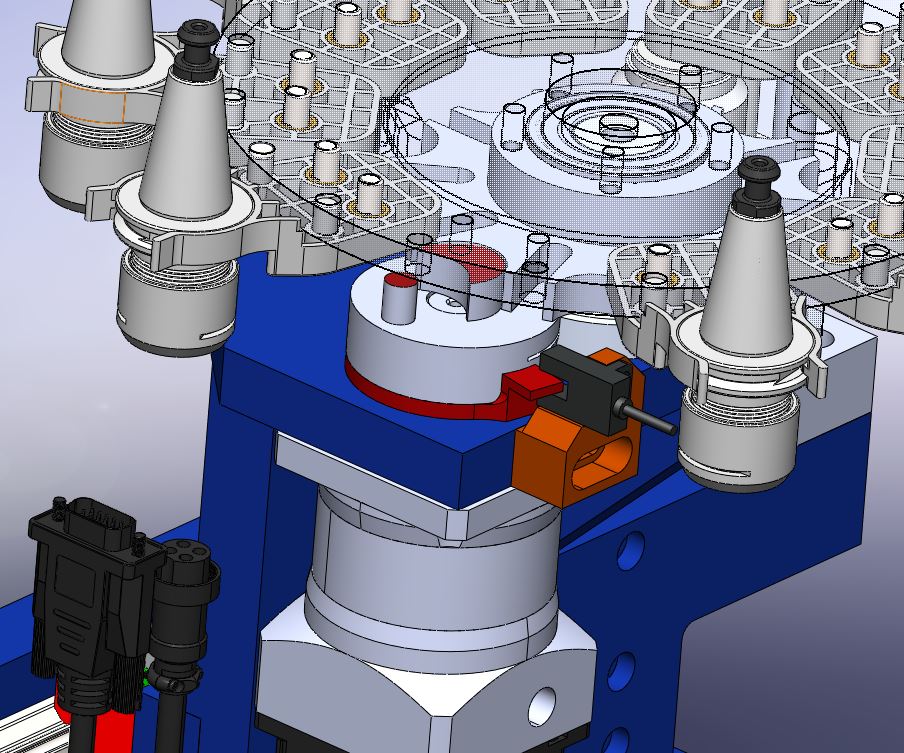

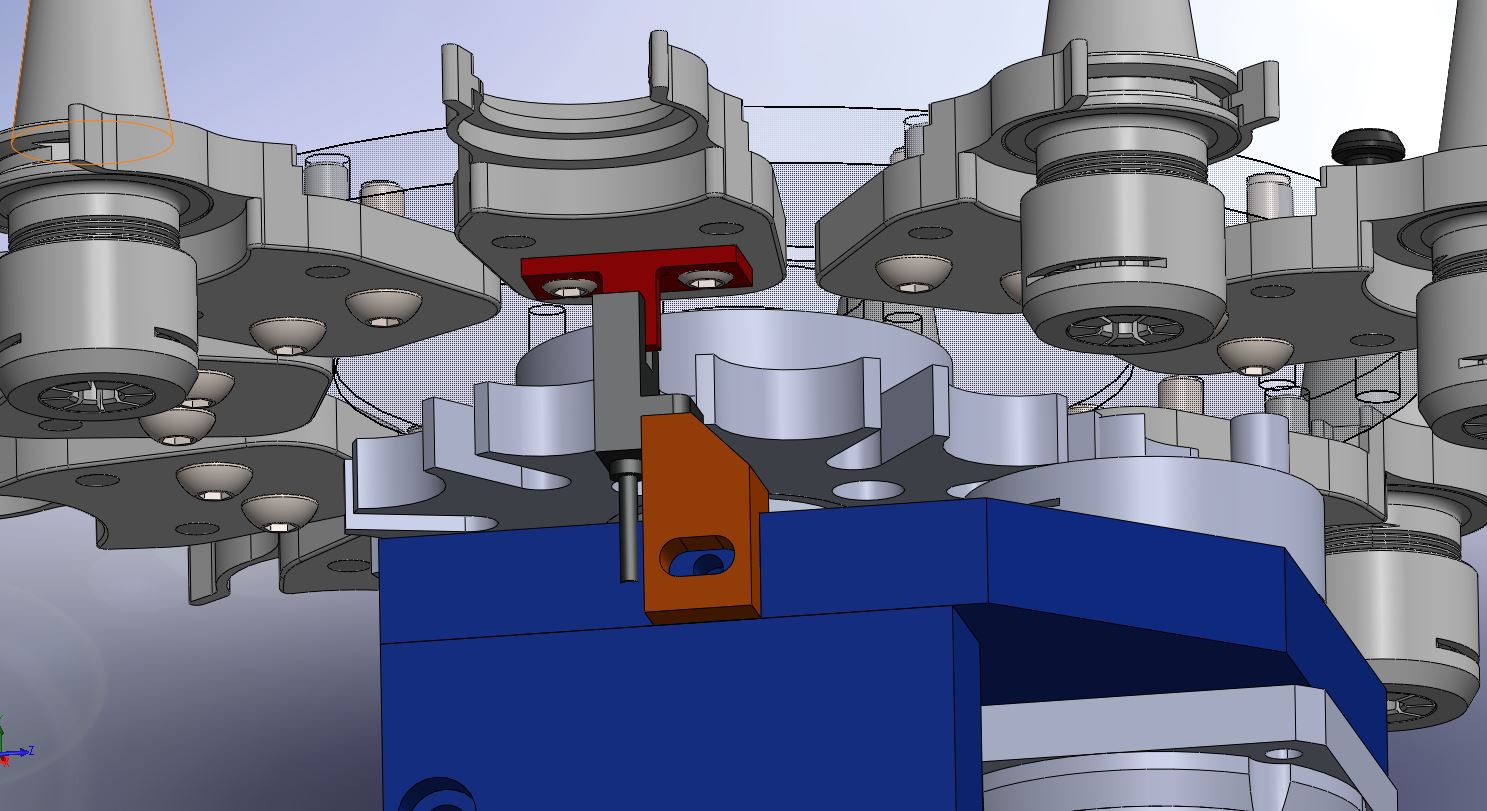

Replied by IB_CnC on topic Probe Basic and Carousel ATC with Geneva and Stepper

Probe Basic and Carousel ATC with Geneva and Stepper

Category: QtPyVCP

- IB_CnC

- IB_CnC

01 May 2025 23:44 - 01 May 2025 23:47

Replied by IB_CnC on topic Probe Basic and Carousel ATC with Geneva and Stepper

Probe Basic and Carousel ATC with Geneva and Stepper

Category: QtPyVCP

- IB_CnC

- IB_CnC

30 Apr 2025 02:18

Replied by IB_CnC on topic Probe Basic and Carousel ATC with Geneva and Stepper

Probe Basic and Carousel ATC with Geneva and Stepper

Category: QtPyVCP

- yngndrw

- yngndrw

27 Apr 2025 16:25 - 27 Apr 2025 16:26

- 3404gerber

- 3404gerber

27 Apr 2025 07:15

Replied by 3404gerber on topic comparing to Grbl, or FluidNC

comparing to Grbl, or FluidNC

Category: Milling Machines

- IB_CnC

- IB_CnC

26 Apr 2025 22:13

Replied by IB_CnC on topic Probe Basic and Carousel ATC with Geneva and Stepper

Probe Basic and Carousel ATC with Geneva and Stepper

Category: QtPyVCP

- spumco

- spumco

20 Apr 2025 21:03

Replied by spumco on topic Determining Angular Scale - Help w/ Microsteps

Determining Angular Scale - Help w/ Microsteps

Category: Configuration Tools

- Jabbery

- Jabbery

19 Apr 2025 01:04

Replied by Jabbery on topic Spindle will not stay running

Spindle will not stay running

Category: General LinuxCNC Questions

- tommylight

19 Apr 2025 00:41

Replied by tommylight on topic Are the program's extents available to the g-code?

Are the program's extents available to the g-code?

Category: General LinuxCNC Questions

- pgf

- pgf

18 Apr 2025 18:30

Replied by pgf on topic Are the program's extents available to the g-code?

Are the program's extents available to the g-code?

Category: General LinuxCNC Questions

- FPM

- FPM

18 Apr 2025 12:01 - 18 Apr 2025 12:03

Replied by FPM on topic converting a tos/intos fngj 40

converting a tos/intos fngj 40

Category: Milling Machines

- theslawek

- theslawek

18 Apr 2025 03:38

Replied by theslawek on topic Need help making rotary axis behave like second spindle

Need help making rotary axis behave like second spindle

Category: Advanced Configuration

Time to create page: 0.689 seconds