NativeCAM is Features renamed

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

25 Nov 2016 17:14 #83293

by FernV

In Tool Change set Milling penetration -> Step down (default is -0.125in or -3.0mm)

Do not forget in Workpiece, Milling params -> Clear through (default is -0.05in or -1.25mm) if you want a task to Milling -> Cut down to -> Through to have the cutter go lower than the bottom of your Workpiece . If you cut to Bottom, the cutter will go down exactly to the bottom of your workpiece.

When cutting a pocket, you usually set to either : User defined, Half, One quarter or Three quarter

Fern

PS, do not forget to check Skip Block before milling. This is a safety feature as mentioned in the ncam.ngc file

Replied by FernV on topic NativeCAM is Features renamed

...if cutting a circle pocket at a depth of one inch, it appears to cut to the full depth in one pass. Is there a way to specify multiple passes...

In Tool Change set Milling penetration -> Step down (default is -0.125in or -3.0mm)

Do not forget in Workpiece, Milling params -> Clear through (default is -0.05in or -1.25mm) if you want a task to Milling -> Cut down to -> Through to have the cutter go lower than the bottom of your Workpiece . If you cut to Bottom, the cutter will go down exactly to the bottom of your workpiece.

When cutting a pocket, you usually set to either : User defined, Half, One quarter or Three quarter

Fern

PS, do not forget to check Skip Block before milling. This is a safety feature as mentioned in the ncam.ngc file

Please Log in or Create an account to join the conversation.

- gmouer

- Offline

- Elite Member

-

Less

More

- Posts: 212

- Thank you received: 9

25 Nov 2016 17:41 #83297

by gmouer

Replied by gmouer on topic NativeCAM is Features renamed

Thanks once again Fern !

I have reloaded the livecd on my bridgeport and updated file which brought me to 2.7.8 for linuxcnc.

All is going smooth, I will be installing NativeCAM shortly but don't expect any problems now.

I can't tell you how much I look forward to using NativeCAM on my mill and really appreciate your work !

George

I have reloaded the livecd on my bridgeport and updated file which brought me to 2.7.8 for linuxcnc.

All is going smooth, I will be installing NativeCAM shortly but don't expect any problems now.

I can't tell you how much I look forward to using NativeCAM on my mill and really appreciate your work !

George

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

25 Nov 2016 21:34 - 25 Nov 2016 21:39 #83316

by FernV

In such case all is needed is the delay after M3, right ?

Regards

Fern

P.S. After reaching the last coords point of a shape, can we just issue M5 or is it really necessary to lead-out first then M5 ?

Replied by FernV on topic Lead in set up

So the THC does the Z movement to detect material and set compensation for material height, isn't it ?my set up has stand alone THC controller, the process is as following.

-At M3 the THC start the material detect process

-unless the material is detected it go back to the piercing high

-start the arc,

-wait for the piercing time,

-send the arc ok signal LinuxCNC

-LinuxCNC start moving

In such case all is needed is the delay after M3, right ?

Then in Preferences dialog, the choice should be made as per machine setup to use a THC controller or a subroutines like mentionned at wiki.linuxcnc.org/cgi-bin/wiki.pl?GmoccapyPlasma am I right ?in the other hand if the THC is implemented in LinuxCNC

most of the times all this process is made in a sub-routine

in both cases, all this code can be inserted as pre-amble and post-amble.

Regards

Fern

P.S. After reaching the last coords point of a shape, can we just issue M5 or is it really necessary to lead-out first then M5 ?

Last edit: 25 Nov 2016 21:39 by FernV. Reason: Added PS

Please Log in or Create an account to join the conversation.

- grijalvap

-

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 63

25 Nov 2016 23:05 #83322

by grijalvap

Replied by grijalvap on topic Lead in set up

correct for the first question

The second question answer is we use an

M3 to start THC

M66 P0 Qxx to wait until arc ok is ready

and the last question

is correct this can be very helpful

The second question answer is we use an

M3 to start THC

M66 P0 Qxx to wait until arc ok is ready

and the last question

is correct this can be very helpful

The following user(s) said Thank You: FernV

Please Log in or Create an account to join the conversation.

- gmouer

- Offline

- Elite Member

-

Less

More

- Posts: 212

- Thank you received: 9

26 Nov 2016 00:52 #83323

by gmouer

Replied by gmouer on topic NativeCAM is Features renamed

Hi Fern,

I have NativeCAM working embedded by launching it from the terminal like the instructions show. I first change to the NativeCAM directory then enter the command you show for mill.ini, linuxcnc with NativeCAM launches nicely.

What I would like to do, and have not had any success is to create a desktop launcher to do this so I don't have to open terminal, change directories and enter the starting command every time. I have not had any luck getting this to work. I believe its a matter of paths to the various files not being found.

Any suggestions on creating a desktop launcher for embedded NativeCAM?

Thanks,

George

I have NativeCAM working embedded by launching it from the terminal like the instructions show. I first change to the NativeCAM directory then enter the command you show for mill.ini, linuxcnc with NativeCAM launches nicely.

What I would like to do, and have not had any success is to create a desktop launcher to do this so I don't have to open terminal, change directories and enter the starting command every time. I have not had any luck getting this to work. I believe its a matter of paths to the various files not being found.

Any suggestions on creating a desktop launcher for embedded NativeCAM?

Thanks,

George

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

26 Nov 2016 07:55 #83329

by FernV

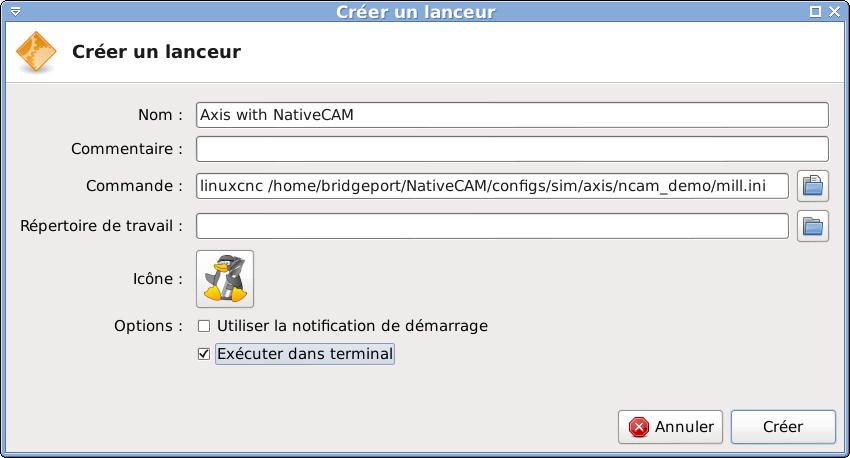

It is not very difficult. Right click anywhere on your Desktop and select 'Create Launcher...'

Fill like this

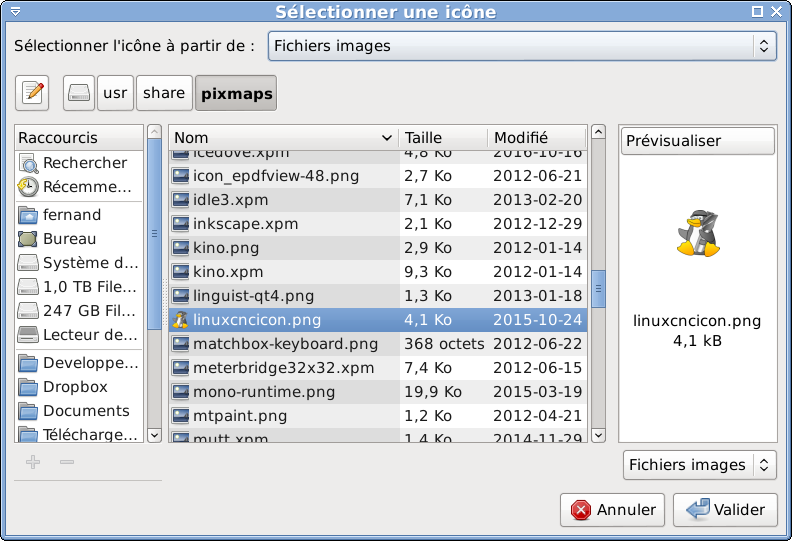

For the icon, select a file like this

Fern

Replied by FernV on topic NativeCAM is Features renamed

Any suggestions on creating a desktop launcher for embedded NativeCAM?

It is not very difficult. Right click anywhere on your Desktop and select 'Create Launcher...'

Fill like this

For the icon, select a file like this

Fern

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21221

- Thank you received: 7246

26 Nov 2016 11:25 #83335

by tommylight

Gmoccapy_plasma is a very nice starting point, it has most information on plasma control in one place.

I also read somewhere here about having a lead out from the cut, it would be nice to have it, as the plasma cutters have a nasty habit of "blowback" when they are switched off and shutting the arc, they tend to leave a nice ding ( burn a bit more material that during normal cutting, and the torch is at stand still while switching off), so adding 2-3mm of lead out would provide for cleaner cuts at the start/stop of the cut.

As for videos, have a look at some of mine, they all use a hal implementation done by someone on this forum a long time ago, and it took me quite some time to modify and make it work for all simple THC that use UP/DOWN/ARCOK signals. This is the method described in the gmoccapy_plasma wiki as being to complicated ( and it is to complicated ). Another method mentioned there is a hal component, there is already one made by BigJT for use with THCAD or other THC, it is much easier to modify and understand but if i remember correctly that still needs a sub for finding the material.

It would be nice to have a comp for automating the procedure of finding the material/retracting to pierce height/firing the torch/waiting for arc ok/waiting for pierce delay/moving to cutting height/enable motion. That can be implemented easily in any config by halcompile and a line in the ini file. This also removes the need for any related Z axis code.

From your stand point, i think you already have everything needed, so just to sum it up:

M3/M5 for every cut

Lead in/out for every cut with the inside/outside option for every cut or for all at once

No Z axis values

Kerf compensation ( tool compensation) also with inside/outside option

Preamble and postamble as needed and subs for every cut

Nothing more, as it would make some things easier for some user but more complicated for others.

Replied by tommylight on topic Lead in set up

This option should be set in Preferences dialog. Not sure yet how this exclusion should be implemented how it would work. All videos I viewed use some way of finding the surface.Well that is correct, in most plasma setups you do not need anything related to z axis, but i know for sure the configs i use do not care if there are Z related codes or not. Some configs do use Z axis, so it is not advisable to remove it completly. Having a button to include or remove Z axis related code would be best.

The G38.x option should also be set once in the Preferences dialogThe configs that do use Z also use some type of G38.x move to find the material and set offsets for every cut so that would need to be added as a preamble that can be edited to suit the needs of different setups. This can be done together with adding M3/M5 to every cut.

Do you think wiki.linuxcnc.org/cgi-bin/wiki.pl?Gmoccapy_Plasma should be my starting point ?

I think adding this delay should be in 'Cutting Params'Another thing that can be added for plasma use is adding a G04 pause after the M3, that is a pierce delay, and needs to be adjustable in 0.1 second increments from 0 to 1 second ( even more if cutting thick material ).

Anything else should be configured ?

I am planning a video but I still need more feedback to help make it really usable.

I think of demo configs using gmoccappy.gmoccapy_plasma and by_interface.mesa.plasma-5i20.

Regards

Fern

Gmoccapy_plasma is a very nice starting point, it has most information on plasma control in one place.

I also read somewhere here about having a lead out from the cut, it would be nice to have it, as the plasma cutters have a nasty habit of "blowback" when they are switched off and shutting the arc, they tend to leave a nice ding ( burn a bit more material that during normal cutting, and the torch is at stand still while switching off), so adding 2-3mm of lead out would provide for cleaner cuts at the start/stop of the cut.

As for videos, have a look at some of mine, they all use a hal implementation done by someone on this forum a long time ago, and it took me quite some time to modify and make it work for all simple THC that use UP/DOWN/ARCOK signals. This is the method described in the gmoccapy_plasma wiki as being to complicated ( and it is to complicated ). Another method mentioned there is a hal component, there is already one made by BigJT for use with THCAD or other THC, it is much easier to modify and understand but if i remember correctly that still needs a sub for finding the material.

It would be nice to have a comp for automating the procedure of finding the material/retracting to pierce height/firing the torch/waiting for arc ok/waiting for pierce delay/moving to cutting height/enable motion. That can be implemented easily in any config by halcompile and a line in the ini file. This also removes the need for any related Z axis code.

From your stand point, i think you already have everything needed, so just to sum it up:

M3/M5 for every cut

Lead in/out for every cut with the inside/outside option for every cut or for all at once

No Z axis values

Kerf compensation ( tool compensation) also with inside/outside option

Preamble and postamble as needed and subs for every cut

Nothing more, as it would make some things easier for some user but more complicated for others.

The following user(s) said Thank You: FernV

Please Log in or Create an account to join the conversation.

- gmouer

- Offline

- Elite Member

-

Less

More

- Posts: 212

- Thank you received: 9

27 Nov 2016 17:27 #83369

by gmouer

Replied by gmouer on topic NativeCAM is Features renamed

Hi Fern,

Thanks for the great help in creating a desktop launcher to NativeCAM. It worked great !

I had the process right before your help BUT for some reason I insist on spelling ncam as nccam ! Obviously that causes problems !

Also, I successfully set up a config with NativeCAM for my bridgeport mill. I look very forward to learning it and using NativeCAM on a regular basis.

Thanks so much for all your work and help.

George

Thanks for the great help in creating a desktop launcher to NativeCAM. It worked great !

I had the process right before your help BUT for some reason I insist on spelling ncam as nccam ! Obviously that causes problems !

Also, I successfully set up a config with NativeCAM for my bridgeport mill. I look very forward to learning it and using NativeCAM on a regular basis.

Thanks so much for all your work and help.

George

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

30 Nov 2016 13:24 #83484

by FernV

Does your ini file exclude a Z axis ? In such case it can be automatically detected and code would be conditional to it.

It means that not 3d would show i.e. flat workpiece and no vertical lead-in or out

Regards

Fern

Replied by FernV on topic Lead in set up

There is any way to remove any Z related stuff, my equipment only have X and Y Axis

Does your ini file exclude a Z axis ? In such case it can be automatically detected and code would be conditional to it.

It means that not 3d would show i.e. flat workpiece and no vertical lead-in or out

Regards

Fern

Please Log in or Create an account to join the conversation.

- grijalvap

-

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 63

30 Nov 2016 16:56 #83490

by grijalvap

Replied by grijalvap on topic Lead in set up

Yes, the configuration excludes the Z axis, it only has X and Y axis, so what you comment should work.

Thanks

Thanks

Please Log in or Create an account to join the conversation.

Time to create page: 0.330 seconds