NativeCAM is Features renamed

- grijalvap

-

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 63

18 Apr 2017 14:59 #91583

by grijalvap

Replied by grijalvap on topic NativeCAM is Features renamed

Ok.

So, basically the way to go is to migrate to Gmoccapy or other GUI?

So, basically the way to go is to migrate to Gmoccapy or other GUI?

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

24 Apr 2017 12:21 #91956

by FernV

Hi George,

If you mill setup has A axis configured would you try this demo and tell me if it looks right ? The tool rotates but the path looks strange. Is it normal ?

You could also try with axis_9axis.ini

Fern

Replied by FernV on topic NativeCAM is Features renamed

I am loving NativeCam. I know it was mentioned that new additions are in the works. I have a request, could 4th rotary axis indexing be added? I am speaking of indexing only, not live 4th axis 3d cutting. I suppose it would need a preference to define if the rotary axis was A, C etc.

Hi George,

If you mill setup has A axis configured would you try this demo and tell me if it looks right ? The tool rotates but the path looks strange. Is it normal ?

You could also try with axis_9axis.ini

Fern

Please Log in or Create an account to join the conversation.

- gmouer

- Offline

- Elite Member

-

Less

More

- Posts: 212

- Thank you received: 9

24 Apr 2017 19:11 - 24 Apr 2017 19:13 #92000

by gmouer

Replied by gmouer on topic NativeCAM is Features renamed

Hi Fern,

I have a project underway on the mill right now so won't be able to try it for a few days. (4th axis not installed right now)

Where do I install the file? Will it give me a icon to pick it as other features do? I am using NativeCam quite a lot now but am pretty unfamiliar with the underlying structure and code.

Your work is extremely appreciated!

George

I have a project underway on the mill right now so won't be able to try it for a few days. (4th axis not installed right now)

Where do I install the file? Will it give me a icon to pick it as other features do? I am using NativeCam quite a lot now but am pretty unfamiliar with the underlying structure and code.

Your work is extremely appreciated!

George

Last edit: 24 Apr 2017 19:13 by gmouer.

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

24 Apr 2017 20:24 #92008

by FernV

Next release will be a MAJOR update

Fern

Replied by FernV on topic NativeCAM is Features renamed

Then you should try it with axis_9axis.ini4th axis not installed right now

This is basically a demo. Simply open it as a project. A few things will not look right because your lib is not updated.Where do I install the file? Will it give me a icon to pick it as other features do?

Next release will be a MAJOR update

Fern

Please Log in or Create an account to join the conversation.

- cncnoob1979

-

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

28 Apr 2017 03:54 #92244

by cncnoob1979

Replied by cncnoob1979 on topic NativeCAM is Features renamed

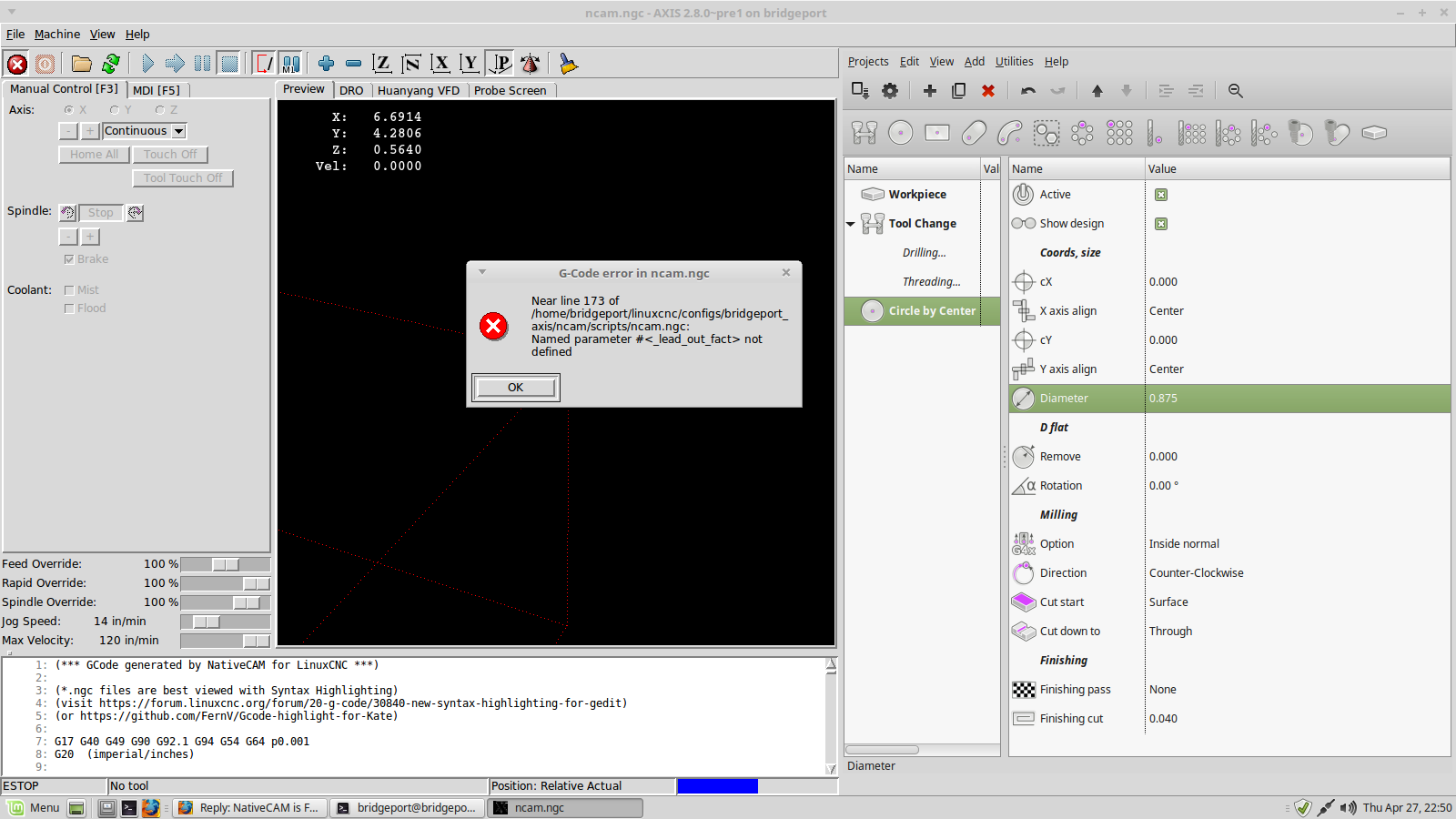

I have been trying to solve this on my own all night.. no avail  I just installed NCam latest and configured it embedded.

I just installed NCam latest and configured it embedded.

I am getting this error no matter what I do.. I'm sure its something that I am doing or not setting correctly. I'm using the latest git pull from FernV github with linuxcnc 2.8~.

The error Im getting is "Named parameter #<_lead_out_fact> not defined"

I have:

a workpiece

a change tool

and a circle of .875

The tool Im using is .5 endmill.

Nothing odd about what I'm doing. I have tried a clean install of linuxcnc and NCam. This fails on either axis or gmoccapy.

I have checked and rechecked my setup. Can anyone point me in the right direction?

INI attached below;

I am getting this error no matter what I do.. I'm sure its something that I am doing or not setting correctly. I'm using the latest git pull from FernV github with linuxcnc 2.8~.

The error Im getting is "Named parameter #<_lead_out_fact> not defined"

I have:

a workpiece

a change tool

and a circle of .875

The tool Im using is .5 endmill.

Nothing odd about what I'm doing. I have tried a clean install of linuxcnc and NCam. This fails on either axis or gmoccapy.

I have checked and rechecked my setup. Can anyone point me in the right direction?

INI attached below;

Warning: Spoiler!

#INCLUDE /home/bridgeport/linuxcnc/configs/bridgeport_axis/xhc-hb04/layout2.inc

[EMC]

# The version string for this INI file.

VERSION = 1.0

MACHINE = bridgeport

DEBUG = 0

[DISPLAY]

# required NativeCAM item :

NCAM_DIR = ncam

# required NativeCAM item :

PROGRAM_PREFIX = ncam/scripts/

# required NativeCAM item :

GLADEVCP = -U --catalog=mill /home/bridgeport/nativecam/ncam.ui

DISPLAY = axis

EMBED_TAB_NAME=Huanyang VFD

EMBED_TAB_COMMAND=halcmd loadusr -Wn vfd gladevcp -c vfd -x {XID} -u handler.py huanyang.glade

EMBED_TAB_NAME=Probe Screen

EMBED_TAB_COMMAND=halcmd loadusr -Wn probe_screen gladevcp -c probe_screen -u python/probe_screen.py -x {XID} probe_icons/probe_screen.glade

EDITOR = kate

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.20000

MIN_SPINDLE_OVERRIDE = 0.050000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 3

INCREMENTS = .1in .05in .01in .005in .001in .0005in .0001in

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 0.250000

MAX_LINEAR_VELOCITY = 2.0

MIN_LINEAR_VELOCITY = 0.010000

DEFAULT_ANGULAR_VELOCITY = 0.250000

MAX_ANGULAR_VELOCITY = 1.000000

MIN_ANGULAR_VELOCITY = 0.010000

GEOMETRY = xyz

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[RS274NGC]

# required NativeCAM item :

SUBROUTINE_PATH = ncam/lib/mill:ncam/lib/utilities

FEATURES=30

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

COMM_WAIT = 0.010

SERVO_PERIOD = 1000000

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[HAL]

HALUI = halui

HALFILE = bridgeport.hal

HALFILE = custom.hal

#***************HB04*****************

HALFILE = LIB:xhc-hb04.tcl

#************************************

POSTGUI_HALFILE = custom_postgui.hal

SHUTDOWN = shutdown.hal

[TRAJ]

AXES = 3

COORDINATES = X Y Z

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

CYCLE_TIME = 0.010

DEFAULT_LINEAR_VELOCITY = 6.0

MAX_LINEAR_VELOCITY = 6.00

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#********************

# Axis X

#********************

[KINS]

KINEMATICS = trivkins

JOINTS = 3

[AXIS_X]

MIN_LIMIT = -17.755

MAX_LIMIT = 0.04

MAX_VELOCITY = 3.10

MAX_ACCELERATION = 5.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 1.003

MIN_FERROR = 1.003

MAX_VELOCITY = 3.10

MAX_ACCELERATION = 5.0

P = 150

I = 0

D = 0

FF0 = 0

FF1 = 2.74

FF2 = 0.003

BIAS = 0

DEADBAND = 0.00009

MAX_OUTPUT = 10

ENCODER_SCALE = -50800

OUTPUT_SCALE = 10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -17.755

MAX_LIMIT = 0.04

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = 0.5

HOME_LATCH_VEL = 0.017

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

HOME_SEQUENCE = 1

#********************

# Axis Y

#********************

[AXIS_Y]

MIN_LIMIT = -11.373

MAX_LIMIT = 0.303

MAX_VELOCITY = 3.10

MAX_ACCELERATION = 5.0

[JOINT_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.003

MIN_FERROR = 0.003

MAX_VELOCITY = 3.10

MAX_ACCELERATION = 5.0

P = 150

I = 0

D = 0

FF0 = 0

FF1 = 2.74

FF2 = 0.003

BIAS = 0

DEADBAND = 0.000059

MAX_OUTPUT = 10

ENCODER_SCALE = -50800

OUTPUT_SCALE = 10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -11.373

MAX_LIMIT = 0.303

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 0.500000

HOME_LATCH_VEL = 0.016667

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

HOME_SEQUENCE = 2

#********************

# Axis Z

#********************

[AXIS_Z]

MIN_LIMIT = -4.465

MAX_LIMIT = 0.069

MAX_VELOCITY = 2.5

MAX_ACCELERATION = 5.0

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.003

MIN_FERROR = 0.003

MAX_VELOCITY = 2.5

MAX_ACCELERATION = 5.0

P = 150

I = 0

D = 0

FF0 = 0

FF1 = 2.74

FF2 = 0.003

BIAS = 0

DEADBAND = 0.000059

MAX_OUTPUT = 10

ENCODER_SCALE = -50800

OUTPUT_SCALE = 10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -4.465

MAX_LIMIT = 0.069

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 0.50000

HOME_LATCH_VEL = 0.016667

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

HOME_SEQUENCE = 0

#********************

# Spindle

#********************

[TOOLSENSOR]

# Control probe rapid feed (in machine units per minute)

RAPID_SPEED = 100

[HOSTMOT2]

# **** This is for info only ****

# DRIVER0=hm2_pci

# BOARD0=5i25

[SPINDLE_9]

P = 0

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 10

#********************

# Handwheel

#********************

[MPG]

HAND_WHEEL_SCALE = 0.00000016

Z_MINUS_LIMIT = 0.000008

[XHC_HB04_CONFIG]

# specify layout = n for LIB:xhc-hb04-layout{n}.cfg files

layout = 2

# coords: specify upto 4 letters from set {x y z a b c u v w}

# coords: switch labels are xyza but any unique 4 letters

# from the set {xyxabcuvw) can be used (if the coord exists)

coords = x y z

# lowpass settings:

# coef: slows rate of change of output, range: 0 < coef < 1

coefs = 1 1 1 1

# scale plus or minus, rotaries may require larger scale factor:

scales = 1 -1 1 1

# jogmode normal(default) or vnormal

jogmode = normal

# sequence 1: 0.001,0.010,0.100,1.000 (mm-based machine)

# sequence 2: 0.001,0.005,0.010,0.020 (inch-based machine)

# sequence 3: 0.001,0.010,0.100

# sequence 4: 0.001,0.005,0.010,0.020,0.050,0.100

# sequence 5: 0.001,0.010,0.050,0.100,1.000

sequence = 2

# require_pendant = yes|no: create xhc-hb04 hal pins when pendant not

# connected at startup

require_pendant = no

# inch_or_mm = in | mm

inch_or_mm = in

# mpg_accels: provision for reduced acceleration for manual mode jogging

mpg_accels = 2 2 1 600

[APPLICATIONS]

APP = xhc-hb04-accels

APP = monitor-xhc-hb04

[XHC_HB04_BUTTONS]

# use button names according to layout file LIB:xhc-hb04-layout{n}.cfg

# note: "start-pause" is connected for standard behavior

# controlling halui.pause/halui.resume/halui.run

# these are examples, edit as required:

goto-zero = halui.mdi-command-00

# synthesized per-axis buttons for goto-zero button:

goto-zero-x = ""

goto-zero-y = ""

goto-zero-z = ""

goto-zero-a = ""

start-pause = std_start_pause

#rewind = halui.program.step

# probe-input for simulating a probe:

#probe-z = motion.probe-input

macro-3 = halui.mdi-command-03

#half = halui.spindle.stop

# synthesized per-axis buttons for half button:

half-x = ""

half-y = ""

half-z = ""

half-a = ""

zero = ""

# synthesized per-axis buttons for zero button:

zero-x = halui.mdi-command-12

zero-y = halui.mdi-command-13

zero-z = halui.mdi-command-14

zero-a = halui.mdi-command-15

safe-z = halui.mdi-command-10

# in this sim, home-all only works first time, hold down till finished:

home = halui.home-all

macro-1 = halui.mdi-command-01

macro-2 = halui.mdi-command-02

spindle = halui.spindle.start

step = xhc-hb04.stepsize-up

mode = ""

macro-6 = halui.mdi-command-06

macro-7 = halui.mdi-command-07

stop = halui.program.stop

reset = halui.estop.activate

[HALUI]

# these are examples, edit as required:

# a halui hal pin is created for each MDI_COMMAND below

# halui.mdi-command-00, halui.mdi-command-01,... etc

MDI_COMMAND=G0 X0 Y0 Z0

MDI_COMMAND=(debug, example: mdi-01)

MDI_COMMAND=(debug, example: mdi-02)

#03 M110: clears notifications

MDI_COMMAND=M110

MDI_COMMAND=(debug, example: mdi-04)

MDI_COMMAND=(debug, example: mdi-05)

MDI_COMMAND=(debug, example: mdi-06)

#07 M101: example print to stdout

MDI_COMMAND=M101

MDI_COMMAND=(debug, example: mdi-08)

MDI_COMMAND=(debug, example: mdi-09)

MDI_COMMAND=(debug, example: mdi-10)

MDI_COMMAND=(debug, example: mdi-11)

#12

MDI_COMMAND= G10 L20 P0 X0

#13

MDI_COMMAND= G10 L20 P0 Y0

#14

MDI_COMMAND= G10 L20 P0 Z0

#15

MDI_COMMAND= G10 L20 P0 C0

[EMC]

# The version string for this INI file.

VERSION = 1.0

MACHINE = bridgeport

DEBUG = 0

[DISPLAY]

# required NativeCAM item :

NCAM_DIR = ncam

# required NativeCAM item :

PROGRAM_PREFIX = ncam/scripts/

# required NativeCAM item :

GLADEVCP = -U --catalog=mill /home/bridgeport/nativecam/ncam.ui

DISPLAY = axis

EMBED_TAB_NAME=Huanyang VFD

EMBED_TAB_COMMAND=halcmd loadusr -Wn vfd gladevcp -c vfd -x {XID} -u handler.py huanyang.glade

EMBED_TAB_NAME=Probe Screen

EMBED_TAB_COMMAND=halcmd loadusr -Wn probe_screen gladevcp -c probe_screen -u python/probe_screen.py -x {XID} probe_icons/probe_screen.glade

EDITOR = kate

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.20000

MIN_SPINDLE_OVERRIDE = 0.050000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 3

INCREMENTS = .1in .05in .01in .005in .001in .0005in .0001in

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 0.250000

MAX_LINEAR_VELOCITY = 2.0

MIN_LINEAR_VELOCITY = 0.010000

DEFAULT_ANGULAR_VELOCITY = 0.250000

MAX_ANGULAR_VELOCITY = 1.000000

MIN_ANGULAR_VELOCITY = 0.010000

GEOMETRY = xyz

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[RS274NGC]

# required NativeCAM item :

SUBROUTINE_PATH = ncam/lib/mill:ncam/lib/utilities

FEATURES=30

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

COMM_WAIT = 0.010

SERVO_PERIOD = 1000000

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[HAL]

HALUI = halui

HALFILE = bridgeport.hal

HALFILE = custom.hal

#***************HB04*****************

HALFILE = LIB:xhc-hb04.tcl

#************************************

POSTGUI_HALFILE = custom_postgui.hal

SHUTDOWN = shutdown.hal

[TRAJ]

AXES = 3

COORDINATES = X Y Z

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

CYCLE_TIME = 0.010

DEFAULT_LINEAR_VELOCITY = 6.0

MAX_LINEAR_VELOCITY = 6.00

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#********************

# Axis X

#********************

[KINS]

KINEMATICS = trivkins

JOINTS = 3

[AXIS_X]

MIN_LIMIT = -17.755

MAX_LIMIT = 0.04

MAX_VELOCITY = 3.10

MAX_ACCELERATION = 5.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 1.003

MIN_FERROR = 1.003

MAX_VELOCITY = 3.10

MAX_ACCELERATION = 5.0

P = 150

I = 0

D = 0

FF0 = 0

FF1 = 2.74

FF2 = 0.003

BIAS = 0

DEADBAND = 0.00009

MAX_OUTPUT = 10

ENCODER_SCALE = -50800

OUTPUT_SCALE = 10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -17.755

MAX_LIMIT = 0.04

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = 0.5

HOME_LATCH_VEL = 0.017

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

HOME_SEQUENCE = 1

#********************

# Axis Y

#********************

[AXIS_Y]

MIN_LIMIT = -11.373

MAX_LIMIT = 0.303

MAX_VELOCITY = 3.10

MAX_ACCELERATION = 5.0

[JOINT_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.003

MIN_FERROR = 0.003

MAX_VELOCITY = 3.10

MAX_ACCELERATION = 5.0

P = 150

I = 0

D = 0

FF0 = 0

FF1 = 2.74

FF2 = 0.003

BIAS = 0

DEADBAND = 0.000059

MAX_OUTPUT = 10

ENCODER_SCALE = -50800

OUTPUT_SCALE = 10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -11.373

MAX_LIMIT = 0.303

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 0.500000

HOME_LATCH_VEL = 0.016667

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

HOME_SEQUENCE = 2

#********************

# Axis Z

#********************

[AXIS_Z]

MIN_LIMIT = -4.465

MAX_LIMIT = 0.069

MAX_VELOCITY = 2.5

MAX_ACCELERATION = 5.0

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.003

MIN_FERROR = 0.003

MAX_VELOCITY = 2.5

MAX_ACCELERATION = 5.0

P = 150

I = 0

D = 0

FF0 = 0

FF1 = 2.74

FF2 = 0.003

BIAS = 0

DEADBAND = 0.000059

MAX_OUTPUT = 10

ENCODER_SCALE = -50800

OUTPUT_SCALE = 10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -4.465

MAX_LIMIT = 0.069

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 0.50000

HOME_LATCH_VEL = 0.016667

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

HOME_SEQUENCE = 0

#********************

# Spindle

#********************

[TOOLSENSOR]

# Control probe rapid feed (in machine units per minute)

RAPID_SPEED = 100

[HOSTMOT2]

# **** This is for info only ****

# DRIVER0=hm2_pci

# BOARD0=5i25

[SPINDLE_9]

P = 0

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 10

#********************

# Handwheel

#********************

[MPG]

HAND_WHEEL_SCALE = 0.00000016

Z_MINUS_LIMIT = 0.000008

[XHC_HB04_CONFIG]

# specify layout = n for LIB:xhc-hb04-layout{n}.cfg files

layout = 2

# coords: specify upto 4 letters from set {x y z a b c u v w}

# coords: switch labels are xyza but any unique 4 letters

# from the set {xyxabcuvw) can be used (if the coord exists)

coords = x y z

# lowpass settings:

# coef: slows rate of change of output, range: 0 < coef < 1

coefs = 1 1 1 1

# scale plus or minus, rotaries may require larger scale factor:

scales = 1 -1 1 1

# jogmode normal(default) or vnormal

jogmode = normal

# sequence 1: 0.001,0.010,0.100,1.000 (mm-based machine)

# sequence 2: 0.001,0.005,0.010,0.020 (inch-based machine)

# sequence 3: 0.001,0.010,0.100

# sequence 4: 0.001,0.005,0.010,0.020,0.050,0.100

# sequence 5: 0.001,0.010,0.050,0.100,1.000

sequence = 2

# require_pendant = yes|no: create xhc-hb04 hal pins when pendant not

# connected at startup

require_pendant = no

# inch_or_mm = in | mm

inch_or_mm = in

# mpg_accels: provision for reduced acceleration for manual mode jogging

mpg_accels = 2 2 1 600

[APPLICATIONS]

APP = xhc-hb04-accels

APP = monitor-xhc-hb04

[XHC_HB04_BUTTONS]

# use button names according to layout file LIB:xhc-hb04-layout{n}.cfg

# note: "start-pause" is connected for standard behavior

# controlling halui.pause/halui.resume/halui.run

# these are examples, edit as required:

goto-zero = halui.mdi-command-00

# synthesized per-axis buttons for goto-zero button:

goto-zero-x = ""

goto-zero-y = ""

goto-zero-z = ""

goto-zero-a = ""

start-pause = std_start_pause

#rewind = halui.program.step

# probe-input for simulating a probe:

#probe-z = motion.probe-input

macro-3 = halui.mdi-command-03

#half = halui.spindle.stop

# synthesized per-axis buttons for half button:

half-x = ""

half-y = ""

half-z = ""

half-a = ""

zero = ""

# synthesized per-axis buttons for zero button:

zero-x = halui.mdi-command-12

zero-y = halui.mdi-command-13

zero-z = halui.mdi-command-14

zero-a = halui.mdi-command-15

safe-z = halui.mdi-command-10

# in this sim, home-all only works first time, hold down till finished:

home = halui.home-all

macro-1 = halui.mdi-command-01

macro-2 = halui.mdi-command-02

spindle = halui.spindle.start

step = xhc-hb04.stepsize-up

mode = ""

macro-6 = halui.mdi-command-06

macro-7 = halui.mdi-command-07

stop = halui.program.stop

reset = halui.estop.activate

[HALUI]

# these are examples, edit as required:

# a halui hal pin is created for each MDI_COMMAND below

# halui.mdi-command-00, halui.mdi-command-01,... etc

MDI_COMMAND=G0 X0 Y0 Z0

MDI_COMMAND=(debug, example: mdi-01)

MDI_COMMAND=(debug, example: mdi-02)

#03 M110: clears notifications

MDI_COMMAND=M110

MDI_COMMAND=(debug, example: mdi-04)

MDI_COMMAND=(debug, example: mdi-05)

MDI_COMMAND=(debug, example: mdi-06)

#07 M101: example print to stdout

MDI_COMMAND=M101

MDI_COMMAND=(debug, example: mdi-08)

MDI_COMMAND=(debug, example: mdi-09)

MDI_COMMAND=(debug, example: mdi-10)

MDI_COMMAND=(debug, example: mdi-11)

#12

MDI_COMMAND= G10 L20 P0 X0

#13

MDI_COMMAND= G10 L20 P0 Y0

#14

MDI_COMMAND= G10 L20 P0 Z0

#15

MDI_COMMAND= G10 L20 P0 C0

Please Log in or Create an account to join the conversation.

- absolut15

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 2

28 Apr 2017 04:15 #92246

by absolut15

Replied by absolut15 on topic NativeCAM is Features renamed

hi cncnoob

i have the same error with my machine.

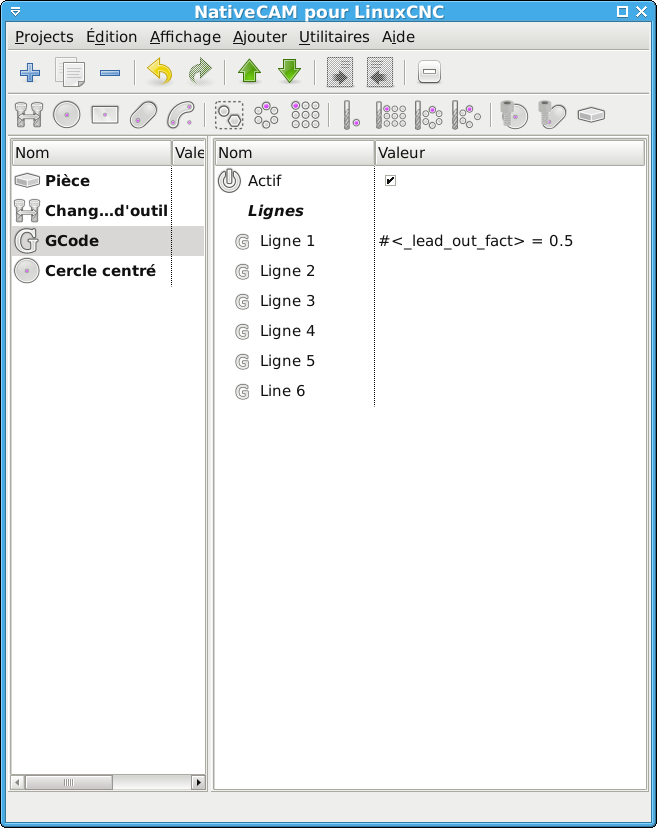

i fixed it with "adding a g-code "

line 1 = #<_lead_out_fact> = 0 (you must try what is the best lead out mode for the thing you milling at the moment)

you can see the different modes in the dro.

hope i can help a bit

i have the same error with my machine.

i fixed it with "adding a g-code "

line 1 = #<_lead_out_fact> = 0 (you must try what is the best lead out mode for the thing you milling at the moment)

you can see the different modes in the dro.

hope i can help a bit

The following user(s) said Thank You: cncnoob1979

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21216

- Thank you received: 7246

28 Apr 2017 09:55 #92251

by tommylight

Replied by tommylight on topic NativeCAM is Features renamed

I have the similar problem on the LATHE part, it does not have an xml template so i just copied one that was close enough.

Basicaly that means that the named parameter is missing on the template.

Anyone got a working lathe template?

Mill and plasma work perfectly for me.

Basicaly that means that the named parameter is missing on the template.

Anyone got a working lathe template?

Mill and plasma work perfectly for me.

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

28 Apr 2017 13:41 #92271

by FernV

Sorry about this, I removed this parameter because it did not show very usefull but it seems the clean-up was not complete.

Use what was proposed by absolut15 for a quick fix :

Add gcode, line 1 = #<_lead_out_fact> = 0.5 (change the value at will)

GCode must be before your Circle

It is just a matter of a few days for a new major update, maybe this week-end

Fern

Replied by FernV on topic NativeCAM is Features renamed

The error Im getting is "Named parameter #<_lead_out_fact> not defined"

Sorry about this, I removed this parameter because it did not show very usefull but it seems the clean-up was not complete.

Use what was proposed by absolut15 for a quick fix :

Add gcode, line 1 = #<_lead_out_fact> = 0.5 (change the value at will)

GCode must be before your Circle

It is just a matter of a few days for a new major update, maybe this week-end

Fern

The following user(s) said Thank You: tommylight, cncnoob1979

Please Log in or Create an account to join the conversation.

- cncnoob1979

-

- Offline

- Platinum Member

-

Less

More

- Posts: 403

- Thank you received: 75

28 Apr 2017 13:53 - 28 Apr 2017 14:04 #92273

by cncnoob1979

Replied by cncnoob1979 on topic NativeCAM is Features renamed

Great! Thanks FernV,

I love using this software. Thank you for creating it and the time it takes to develop and support us!

I love using this software. Thank you for creating it and the time it takes to develop and support us!

Last edit: 28 Apr 2017 14:04 by cncnoob1979.

Please Log in or Create an account to join the conversation.

- gmouer

- Offline

- Elite Member

-

Less

More

- Posts: 212

- Thank you received: 9

28 Apr 2017 14:08 #92274

by gmouer

Hi Fern,

I did not have much luck getting the demo to run. Truth is that I have no experience yet with actually using a 4th axis with linuxcnc. The toolpath displays for 4th axis work are not something I have gotten a grasp of yet. I wish I could be of more help.

Andy Pugh has a 4th axis he has shown and also is far more experienced, maybe he could proof the NativeCam 4th axis operation.

Replied by gmouer on topic NativeCAM is Features renamed

I am loving NativeCam. I know it was mentioned that new additions are in the works. I have a request, could 4th rotary axis indexing be added? I am speaking of indexing only, not live 4th axis 3d cutting. I suppose it would need a preference to define if the rotary axis was A, C etc.

Hi George,

If you mill setup has A axis configured would you try this demo and tell me if it looks right ? The tool rotates but the path looks strange. Is it normal ?

You could also try with axis_9axis.ini

Fern

Hi Fern,

I did not have much luck getting the demo to run. Truth is that I have no experience yet with actually using a 4th axis with linuxcnc. The toolpath displays for 4th axis work are not something I have gotten a grasp of yet. I wish I could be of more help.

Andy Pugh has a 4th axis he has shown and also is far more experienced, maybe he could proof the NativeCam 4th axis operation.

Please Log in or Create an account to join the conversation.

Time to create page: 0.146 seconds