Useful Plasma Thread

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

29 Aug 2018 00:27 - 29 Aug 2018 02:02 #116752

by Grotius

Replied by Grotius on topic Useful Plasma Thread

@John,

Thanks for your wishes. You will see difficult item's are easy'er for me, according to the American Belbin methode, where i was the plant. www.belbin.com/about/belbin-team-roles/ see section plant.

When i started linuxcnc i wanted to stop every time because my limited python programming knowledge. But i held on.

One day i contacted Norbert for making a custom screen for me.

I started with the gnipsel gui in a hot summer of 2017. My pc was outside on the table. But my knowlegde of linux was zero.

The most important reason to held on is, i wanted to have a pc system suitable for cnc and a system that was relaiable and i could use for over 10 years on my machines.

I agree we are at the hard part. I see it as follow's. The plasma system is working very good now on the external offset branche.

So there i do a few more thing's to get it like we would. My next plan is to provide a free dxf to gcode module for linuxcnc. And how this is going to work. I am now thinking how to do that without 4500 lines of python code.

The solution can be very simple, if someone has an idea, it can be the solution. The solution can be 400 lines of c code.

If i look at the inkscape python code for gcodetools output, 4601 lines, i see it's not very well commented, some lines are abra cadabra. But that is a way of

useless open source coding. In my coding style, all is clear alway's. And i am not a top coder. I am just starting up to the next level.

Open source coding has to be understandable for all languages. It needs more comment's, etc. That is a prior statement for open source. But Nick is a good guy. He is very clever.

But my winter project will be a cad/cam module usable for us all.

At this moment i think a new blanco c code will be the best to start with.

Python is not my first programming language to write in. I like c very much. It's a very basic language and used to compile to real time. For me c works the best.

So if we calculate a real time tool kerf offset, or milling offset's with the component, it's no problem.

According the current g-code and machine xy positions we can calculate the external offset's xy value. We can calculate this perendiculair to circulair object's, or every object, shape is not important. In c this is not very difficult. I think i can do this within 400 lines of code.

The benefit's of real time correction's : if your milling or turning or plasma output product is getting 0.01 smaller, you can set the correction value directly.... Gcode variables, PP's, etc. It has all not that capabilities. The program has not have to being stopped to change value's. Stadey go on. We change the value in real time environment. 20 times better.

Gcode variables, PP's, etc. It has all not that capabilities. The program has not have to being stopped to change value's. Stadey go on. We change the value in real time environment. 20 times better.

A next example :

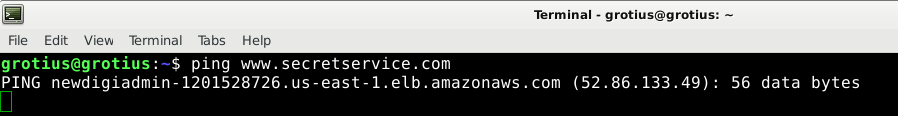

If you ping the secret service, you get this in terminal :

If you type it in google you get no secret service ....

You get this : www.yeah.com

So nothing is what is seems to be. In other words. Write a coded text with Israel and see what happens.

In the past Iran was attacked by America an Israel on their nuclear labratory with a brand new virus.

Thanks for your wishes. You will see difficult item's are easy'er for me, according to the American Belbin methode, where i was the plant. www.belbin.com/about/belbin-team-roles/ see section plant.

When i started linuxcnc i wanted to stop every time because my limited python programming knowledge. But i held on.

One day i contacted Norbert for making a custom screen for me.

I started with the gnipsel gui in a hot summer of 2017. My pc was outside on the table. But my knowlegde of linux was zero.

The most important reason to held on is, i wanted to have a pc system suitable for cnc and a system that was relaiable and i could use for over 10 years on my machines.

I agree we are at the hard part. I see it as follow's. The plasma system is working very good now on the external offset branche.

So there i do a few more thing's to get it like we would. My next plan is to provide a free dxf to gcode module for linuxcnc. And how this is going to work. I am now thinking how to do that without 4500 lines of python code.

The solution can be very simple, if someone has an idea, it can be the solution. The solution can be 400 lines of c code.

If i look at the inkscape python code for gcodetools output, 4601 lines, i see it's not very well commented, some lines are abra cadabra. But that is a way of

useless open source coding. In my coding style, all is clear alway's. And i am not a top coder. I am just starting up to the next level.

Open source coding has to be understandable for all languages. It needs more comment's, etc. That is a prior statement for open source. But Nick is a good guy. He is very clever.

But my winter project will be a cad/cam module usable for us all.

At this moment i think a new blanco c code will be the best to start with.

Python is not my first programming language to write in. I like c very much. It's a very basic language and used to compile to real time. For me c works the best.

So if we calculate a real time tool kerf offset, or milling offset's with the component, it's no problem.

According the current g-code and machine xy positions we can calculate the external offset's xy value. We can calculate this perendiculair to circulair object's, or every object, shape is not important. In c this is not very difficult. I think i can do this within 400 lines of code.

The benefit's of real time correction's : if your milling or turning or plasma output product is getting 0.01 smaller, you can set the correction value directly....

A next example :

If you ping the secret service, you get this in terminal :

If you type it in google you get no secret service ....

You get this : www.yeah.com

So nothing is what is seems to be. In other words. Write a coded text with Israel and see what happens.

In the past Iran was attacked by America an Israel on their nuclear labratory with a brand new virus.

Last edit: 29 Aug 2018 02:02 by Grotius.

Please Log in or Create an account to join the conversation.

- scubawarm

-

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 2

29 Aug 2018 02:29 #116757

by scubawarm

Replied by scubawarm on topic Useful Plasma Thread

WOW:. I asked the question about torch width offsets and really started a dust storm. I didn't mean to side track everyone.

I am currently using a comercial nesting postproser software called Radan on our punch/plasma Whitney machine. And in fact when the question of lead-ins and lead-outs was brought up... I realized I'm not even sure how it works. Which is even more difficult because you prepunch a hole for the pierce.

I'll run a simple program tomorrow with one part nested inside another with easy dimensions to see what that actually sends to the controller.

I am currently using a comercial nesting postproser software called Radan on our punch/plasma Whitney machine. And in fact when the question of lead-ins and lead-outs was brought up... I realized I'm not even sure how it works. Which is even more difficult because you prepunch a hole for the pierce.

I'll run a simple program tomorrow with one part nested inside another with easy dimensions to see what that actually sends to the controller.

Please Log in or Create an account to join the conversation.

- scubawarm

-

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 2

29 Aug 2018 18:40 - 29 Aug 2018 18:48 #116806

by scubawarm

Replied by scubawarm on topic Useful Plasma Thread

OK made a part that is 10" square with a 8" square center cutout.

Placed 1 inch from the origin.

The lead ins have been exaggerated for the example. Inter leading is .5" Arc at 60 degrees as well as the lead-out mid-bottom. Exterior is simple lead-in on the upper right corner.

The software shows all the torch lines including the lead ins... From the code you can see the lead-ins are done with D0 (no torch compensation) and when it gets to the part switches to D01.

With the actual part dimensions given.

NOTE: After further review... the lead-in is with a D0 but at the part dimension... this what we have been running for years but seems wrong... LOL

Again this is a punch/plasma machine and therefore punch the pierce locations and hit the side wall of the punched hole to start.

(/CL,1,20000:)

(/CL,2,69000:)

(WORK CLAMP POSITIONS)

(PLATE LENGTH X : 96 )

(PLATE LENGTH Y : 48 )

(MATERIAL : HR - A709 Gr36 )

(THICKNESS : 0.25 )

(T1 0.250 in dia Ang 0 CI)

(T41 0.068 in dia Ang 0 PL)

N01G00

N02G70G90M42

N03G00X0.Y40.M87

N04(LOAD MATERIAL)

N05M85

N06Y60.

N07M06(LOAD MTN: 1 10250)

N08(Load Tool: 0.25 in CIRCULAR 0 DEGS)

N09G39

N10M42M55M62M75

N11X5.539Y9.633

N12X11.034Y.419

N13M85

N14G00Y60.

N15M06(REMOVE PUNCH DIE AND STRIPPER)

N16M42(CUTTING FOLLOWS)

N17G36

N18(Plasma:)

N19G00X5.567Y9.75

N20M17

N21G41D01

N22G03X6.Y10.I-.433J.25F100.

N23G01X10.

N24Y2.

N25X2.

N26Y10.

N27X6.

N28G03X6.433Y9.75I0.J.5

N29G40D0.

N30M18M00

N31G00X11.Y.534

N32M17

N33G41D01

N34G01Y.966F100.

N35Y11.

N36X1.

N37Y1.

N38X11.034

N39G40D0.

N40M18M00(RP)

N41M99M30

%

Placed 1 inch from the origin.

The lead ins have been exaggerated for the example. Inter leading is .5" Arc at 60 degrees as well as the lead-out mid-bottom. Exterior is simple lead-in on the upper right corner.

The software shows all the torch lines including the lead ins... From the code you can see the lead-ins are done with D0 (no torch compensation) and when it gets to the part switches to D01.

With the actual part dimensions given.

NOTE: After further review... the lead-in is with a D0 but at the part dimension... this what we have been running for years but seems wrong... LOL

Again this is a punch/plasma machine and therefore punch the pierce locations and hit the side wall of the punched hole to start.

(/CL,1,20000:)

(/CL,2,69000:)

(WORK CLAMP POSITIONS)

(PLATE LENGTH X : 96 )

(PLATE LENGTH Y : 48 )

(MATERIAL : HR - A709 Gr36 )

(THICKNESS : 0.25 )

(T1 0.250 in dia Ang 0 CI)

(T41 0.068 in dia Ang 0 PL)

N01G00

N02G70G90M42

N03G00X0.Y40.M87

N04(LOAD MATERIAL)

N05M85

N06Y60.

N07M06(LOAD MTN: 1 10250)

N08(Load Tool: 0.25 in CIRCULAR 0 DEGS)

N09G39

N10M42M55M62M75

N11X5.539Y9.633

N12X11.034Y.419

N13M85

N14G00Y60.

N15M06(REMOVE PUNCH DIE AND STRIPPER)

N16M42(CUTTING FOLLOWS)

N17G36

N18(Plasma:)

N19G00X5.567Y9.75

N20M17

N21G41D01

N22G03X6.Y10.I-.433J.25F100.

N23G01X10.

N24Y2.

N25X2.

N26Y10.

N27X6.

N28G03X6.433Y9.75I0.J.5

N29G40D0.

N30M18M00

N31G00X11.Y.534

N32M17

N33G41D01

N34G01Y.966F100.

N35Y11.

N36X1.

N37Y1.

N38X11.034

N39G40D0.

N40M18M00(RP)

N41M99M30

%

Last edit: 29 Aug 2018 18:48 by scubawarm.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

29 Aug 2018 19:54 #116819

by islander261

Replied by islander261 on topic Useful Plasma Thread

scubawarm

That is exactly how my old mill works (for cutter diameter compensation). Position tool to start of leadin, set G41 and side of cut, then follow offset (cutter comp.) path. If every thing is set correctly you will end up with a correct sized part. The leadin must be longer than 1/2 of the cutter diameter (usually not a problem with plasma). LinuxCNC doesn't need block (line) numbers and by convention they aren't used. I know my old mill control can't work without them.

John

That is exactly how my old mill works (for cutter diameter compensation). Position tool to start of leadin, set G41 and side of cut, then follow offset (cutter comp.) path. If every thing is set correctly you will end up with a correct sized part. The leadin must be longer than 1/2 of the cutter diameter (usually not a problem with plasma). LinuxCNC doesn't need block (line) numbers and by convention they aren't used. I know my old mill control can't work without them.

John

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

02 Sep 2018 16:11 - 02 Sep 2018 16:31 #116980

by Grotius

Replied by Grotius on topic Useful Plasma Thread

Hi,

I updated the files. github.com/michelwijnja/external_offsets_adaptive_feed

Now restart at certain line is workng and keyboard is working to move x, y, z and a axis.

A russian guy had a error request on my git channel. It was a test file : THC2_REV. So i deleted this file. Problem solved.

github.com/michelwijnja/external_offsets_adaptive_feed/issues/1

I updated the files. github.com/michelwijnja/external_offsets_adaptive_feed

Now restart at certain line is workng and keyboard is working to move x, y, z and a axis.

A russian guy had a error request on my git channel. It was a test file : THC2_REV. So i deleted this file. Problem solved.

github.com/michelwijnja/external_offsets_adaptive_feed/issues/1

Last edit: 02 Sep 2018 16:31 by Grotius.

Please Log in or Create an account to join the conversation.

- scubawarm

-

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 2

04 Sep 2018 22:00 - 05 Sep 2018 09:51 #117074

by scubawarm

Replied by scubawarm on topic Useful Plasma Thread

OK... Compiled your code.

Trying to get an Axis .hal and .ini that runs converted to your screen.

Few things that are making it more difficult. Mesa, servo vs steppers, Ethernet vs PPort , and English vs Metric units.

Do you have a listing of variables you have added to better track what needs to come with your configuration?

Here is what I'm getting...

Starting LinuxCNC...

Starting LinuxCNC server program: linuxcncsvr

Loading Real Time OS, RTAPI, and HAL_LIB modules

Starting LinuxCNC IO program: io

emc/iotask/ioControl.cc 768: can't load tool table.

Starting HAL User Interface program: halui

Found file(REL): ./grotius.hal

Shutting down and cleaning up LinuxCNC...

Killing task linuxcncsvr, PID=27809

Removing HAL_LIB, RTAPI, and Real Time OS modules

Removing NML shared memory segments

Debug file information:

./grotius.hal:1: Unknown command ''

27809

PID TTY STAT TIME COMMAND

Stopping realtime threads

Unloading hal components

Note: Using POSIX realtime

Trying to get an Axis .hal and .ini that runs converted to your screen.

Few things that are making it more difficult. Mesa, servo vs steppers, Ethernet vs PPort , and English vs Metric units.

Do you have a listing of variables you have added to better track what needs to come with your configuration?

Here is what I'm getting...

Starting LinuxCNC...

Starting LinuxCNC server program: linuxcncsvr

Loading Real Time OS, RTAPI, and HAL_LIB modules

Starting LinuxCNC IO program: io

emc/iotask/ioControl.cc 768: can't load tool table.

Starting HAL User Interface program: halui

Found file(REL): ./grotius.hal

Shutting down and cleaning up LinuxCNC...

Killing task linuxcncsvr, PID=27809

Removing HAL_LIB, RTAPI, and Real Time OS modules

Removing NML shared memory segments

Debug file information:

./grotius.hal:1: Unknown command ''

27809

PID TTY STAT TIME COMMAND

Stopping realtime threads

Unloading hal components

Note: Using POSIX realtime

Last edit: 05 Sep 2018 09:51 by scubawarm.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

05 Sep 2018 09:51 #117087

by Grotius

Replied by Grotius on topic Useful Plasma Thread

Hi Scuba.

I have no list of variables. At the moment.

Are you using mesa? This config we can

Make a hal example for. At this moment the hal files are configured for parport.

If you have a working mesa config i can help you with making it ready for the grotius gui.

Your debug info looks good. There is one problem in hal. Line 1

I have no list of variables. At the moment.

Are you using mesa? This config we can

Make a hal example for. At this moment the hal files are configured for parport.

If you have a working mesa config i can help you with making it ready for the grotius gui.

Your debug info looks good. There is one problem in hal. Line 1

Please Log in or Create an account to join the conversation.

- scubawarm

-

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 2

05 Sep 2018 14:25 #117108

by scubawarm

Replied by scubawarm on topic Useful Plasma Thread

Ya... No idea what was happening with that file... must have been some garbage I couldn't see... Getting it to fire a little more now...

I really didn't make many changes to these files... Other then changes that are hardware related. It is so hard to tell what some of these things are for. You don't have very many things that need to be defined in the HAL?

But now I get this error...

Debug file information:

Note: Using POSIX realtime

Traceback (most recent call last):

File "/home/superman/linuxcnc-grotius/bin/grotius", line 23, in <module>

import xlsxwriter

ImportError: No module named xlsxwriter

13842

I really didn't make many changes to these files... Other then changes that are hardware related. It is so hard to tell what some of these things are for. You don't have very many things that need to be defined in the HAL?

But now I get this error...

Debug file information:

Note: Using POSIX realtime

Traceback (most recent call last):

File "/home/superman/linuxcnc-grotius/bin/grotius", line 23, in <module>

import xlsxwriter

ImportError: No module named xlsxwriter

13842

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

06 Sep 2018 19:50 - 06 Sep 2018 20:16 #117162

by Grotius

Replied by Grotius on topic Useful Plasma Thread

Hi Scuba,

Haha, No module named xlsxwriter

In the github readme it say's to install this via synaptic package manager.

But faster is like this :

Open terminal :

sudo apt-get install xlsxwriter

This is for writing and reading tool data to excel files. This we need later on to import tool list's, like Hypertherm or Thermal Dynamic's libraries. At this moment it can write your tool data to excel file. Loading the tool data from excel i have to do.

It is working with text files, but Rodw and me have choosed for excel files. Rodw likes sql more. But for me too difficult at this

moment to invest time in.

You only have to edit the postgui.hal file and replace the parport section's, about 5 lines. This file has a very easy setup.

For Mesa ad card, Voltage in is present and working.

Current use is a sample raw voltage input value, taken from the grotius screen. You see this in postgui.hal.

If your Mesa ad input value is working, replace the sample grotius gui input to your real input value. If you don't know how to,

i can help you with this.

Your core hal file's you can use and replace with grotius.hal in your grotius.ini file.

So it is not very difficult to do. I tested it on a old laptop this week. Loaded the axis simulation hal files. This also worked.

So i will also provide a simulation version soon. 800x600 screen resolution's are really a problem. So i must make a choice soon

for the minimal screen resolution or provide a second screen for very low resolution's. Scaling screen's 0.9 or 0.8 is not possible in Glade.

But first i must test the auto restart function at the machine. I solved 2 item's last week. The keyboard buttons to move axis.

And the restart at certain line (tested with line 25500)function. So now we are really far in the process. Everything become's more easye'r to program for me now

through experience. I cutted several hours with this config, and i am really impressed so far. It beat's mach3 in every way

when i am finisched with this gui.

Haha, No module named xlsxwriter

In the github readme it say's to install this via synaptic package manager.

But faster is like this :

Open terminal :

sudo apt-get install xlsxwriter

This is for writing and reading tool data to excel files. This we need later on to import tool list's, like Hypertherm or Thermal Dynamic's libraries. At this moment it can write your tool data to excel file. Loading the tool data from excel i have to do.

It is working with text files, but Rodw and me have choosed for excel files. Rodw likes sql more. But for me too difficult at this

moment to invest time in.

You only have to edit the postgui.hal file and replace the parport section's, about 5 lines. This file has a very easy setup.

For Mesa ad card, Voltage in is present and working.

Current use is a sample raw voltage input value, taken from the grotius screen. You see this in postgui.hal.

If your Mesa ad input value is working, replace the sample grotius gui input to your real input value. If you don't know how to,

i can help you with this.

Your core hal file's you can use and replace with grotius.hal in your grotius.ini file.

So it is not very difficult to do. I tested it on a old laptop this week. Loaded the axis simulation hal files. This also worked.

So i will also provide a simulation version soon. 800x600 screen resolution's are really a problem. So i must make a choice soon

for the minimal screen resolution or provide a second screen for very low resolution's. Scaling screen's 0.9 or 0.8 is not possible in Glade.

But first i must test the auto restart function at the machine. I solved 2 item's last week. The keyboard buttons to move axis.

And the restart at certain line (tested with line 25500)function. So now we are really far in the process. Everything become's more easye'r to program for me now

through experience. I cutted several hours with this config, and i am really impressed so far. It beat's mach3 in every way

when i am finisched with this gui.

Last edit: 06 Sep 2018 20:16 by Grotius.

Please Log in or Create an account to join the conversation.

- scubawarm

-

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 2

06 Sep 2018 20:40 #117165

by scubawarm

Replied by scubawarm on topic Useful Plasma Thread

Gulp... Sorry I missed that... In the process of moving everything to the floor so may be a few days before I get running again... But plan on working on it over the weekend if need be.

Had an axis running other than it was not connected to the motors yet so it would error out when it was told to move. (ie Time to go live)

Excited to see your screen.

Had an axis running other than it was not connected to the motors yet so it would error out when it was told to move. (ie Time to go live)

Excited to see your screen.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.109 seconds