Another plasma component...

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

So on an M3, an air ram shoots the pen down and turns on the engraver airflow and allows marking and engraving operations and enough noise to wake the dead!

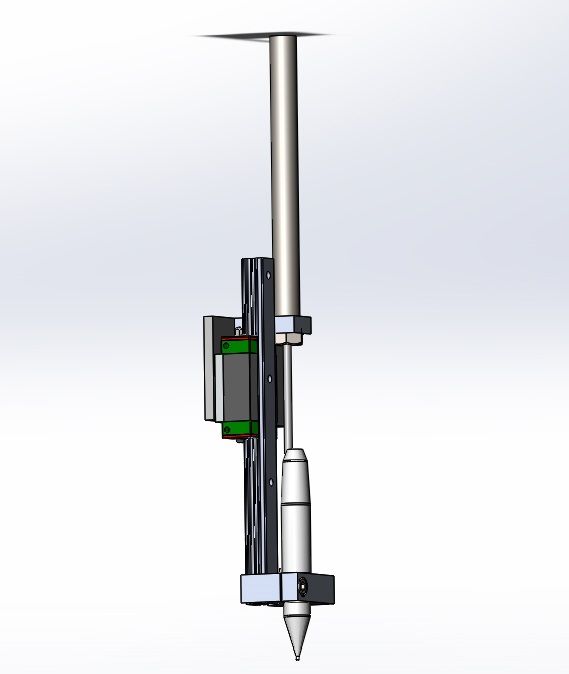

Here is what I had in mind if I ever build it.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

I've not used one but Air scribes are often offered on low end tables. You need two air circuits. One low pressure one with its own regulator to control the downward pressure applied via an air ram and another high pressure one where the air passes through an oiler to operate the scribe itself. A good one is worth aout $500 and the Chicago Pneumatic one is considered the gold standard. www.cp.com/en-au/tools/products/percussi...ngraving-pens/cp9361

Ive got a Chicargo Pneumatic scribe on mine. I have not used it yet since I built the table. Ill post some pics later when the machine is finished cutting.

I plan on using it for marking lines for Jigs and fixtures I am making for our workshop. I am going to built a adjustable angle jig and I will mark the angles on the adjustable plate with the scribe.

I am hoping it works out as well in real life as it does in my head.

Here is what I had in mind if I ever build it.

Hopefully you get the bug and finish it after seeing mine working! Just got it get it working first!

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

Hopefully you get the bug and finish it after seeing mine working! Just got it get it working first!

Well I have got everything here including the scribe. (and have had for a few years)

This is the scribe I bought

It had reasonable reviews and spare parts are available. It will work nice I think. My mate has used one to engrave plastic tags etc on his mill minus the air ram to control the pressure and he got good results.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

Funnily I am the same with my projects at home, I have lots of parts I have brought years ago but still have not gotten around to putting together. I just had a son born a couple of months ago and the way I am going he will be old enough to finish my projects before I get around to them!

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

So how do you tell the air scribe to operate instead of the plasma?So on an M3, an air ram shoots the pen down and turns on the engraver airflow and allows marking and engraving operations and enough noise to wake the dead!

I guess you still need to prove somehow as well.

Now I am curious.

Gosh it's taking me a long time to type this, I am down at the coast and using my phone (horrible thing)

Edit: PROBE

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

The pin spindle.1.on would fire some air solenoids

Andy is the one who wrote it.

linuxcnc.org/docs/devel/html/gcode/m-code.html#mcode:m3-m4-m5

And you would have to define a plasma tool and an engraver tool in the tool table with the offsets.

In plasmac style, you might have to build a dwell into it to allow the air ram to travel down before setting spindle.1.at speed. I have not played with it, but I thought there might need to be an adjustable stop to limit the height above the material to reduce this dwell.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

The Chicago Pneumatic scribe mounted to a aluminum mounting plate.

All of the hardware to make it work, Oiler first then pressure regulators and solenoids.

Attachment not found

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

A bit of a issue I have come across,

When I am cutting out holes with the THC turned off, At the end of the hole when the torch is cutting into the overcut position, The Z axis will raise up signficantly at the end of cut,

This is causing some of my centers of the holes to not be cut through as the torch lifts before it cuts the left over material away.

I have only noticed it on thicker sheets 20mm thicker and up.

Any idea why the torch is moving upwards?

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.