Another plasma component...

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11624

- Thank you received: 3913

Rod

I really don't know what to say, at some point we all need to get the correct .ini values for our tables. When I got mine set correctly most everything seems to be working correctly. The G54 Z offest had no effect on getting rid of the Pogo stick on my system, only the correct MIN_LIMIT fixed it ( my Zmax is at the top of travel, if your directions are reversed then it will be opposite). I only set the G54 Z offset once and Gmoccapy seems to remember it. The G54 X & Y offsets are set to the work piece origin or zero once for each work piece. On my system the G54 X & Y offsets are always 0 at startup.

John

John thanks. pretty sure my Zmax is at the top of travel. I'm just going up to the shed now. I kinda think my zmin is too low below the cutting surface so the probe height is lower than the material surface. So the probe is triggered when plasmac is not expecting it

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

If start of cut within n distance of end of last cut then skip IHS providing:

THC was active on the last cut and no errors were detected on the last cut.

Well that is the theory anyway...

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2345

When can i download a Linuxcnc release of this plasma version?

Can i do a git clone command for this version and install it as rip-environment?

I looked back into the post's of this topic yesterday. I mentioned it has negative adaptive feed and externall offset's branche included.

Maybe i can look at it and do some dry run experiments.

Don't forget to include a seperate simulation version. Just like in Axis !

Thanks !

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Rod,rodw wrote:

Gmoccappy macro buttons sounds like they are the go here. One for touch off x,y and another to probe for Z0 to set the G54 Z offset.

Just use the touchoff buttons shown at the bottom of Gmoccapy in manual mode.

Grotius,Grotius wrote:

When can i download a Linuxcnc release of this plasma version?

Can i do a git clone command for this version and install it as rip-environment?

Yes you can clone and run as RIP, there is a link on the first post in this thread.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

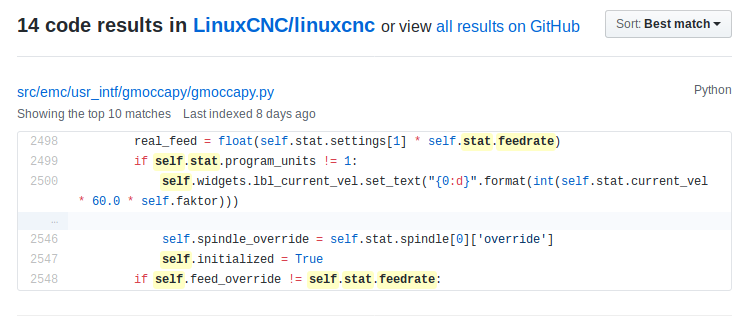

I see the same here, it appears that it may be a Gmoccapy thing as the velocity display in Axis works fine. It doesn't seem related to timing as the DRO's seem to update ok.islander 261 wrote:

The feedrate displayed on the Gmoccapy active Gcode and feedrate frame only intermittently updated to current feedrate. I couldn't detect any pattern to what was going on but I was seeing the correct speed with a halmeter but the wrong one on the UI and then sometimes it was correct.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

Thank you, I think that the IHS Skip distance should be from the last probe location. At the end of the cut you really are only assuming you are at the correct height. For me at least the IHS Skip needs to work whether the THC was active or not the last cut. This may explain part of the behavior I saw today.

John

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Yes, because you have a good THCAt the end of the cut you really are only assuming you are at the correct height

Basically I followed a HT doc I had read.

If you want I could probably make the type of IHS skip a selection from a bit pin.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

Yes, the Plasmac THC works very well. My problem is at least 40% of the cuts I make are without THC. As luck would have it most of these cuts are really close together and I don't like probing into the last pierces slag pile. So yes a pin or a check box to select pierce or end of cut reference.

I looked at the Gmoccapy Glade file and Gmoccapy python handler and it looks like it gets the current feedrate from self.stat.feedrate which is hooked to the LinuxCNC internals some how. Part of this code is well beyond my limited Python and LinuxCNC internals knowledge. Are you sure the remap of the F blocks doesn't mess this up some how? I do know that on my system the displayed F block is always the last non zero one and usually follows the F block in Gcode closely.

John

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

My slats are pretty level, say about +/- 1.5mm. So I just had my Z at machine Z 0 and took a tape measure and measured down to the top of the slats from the torch shield end. I used this measurement as my MIN_LIMIT and a little bit less for my G54 Z offset. The G54 Z offset is only so your DRO makes sense when cutting. Mine is close right now, close enough I don't need to do math in my head to tell what is happening in the cut.

John

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2345

NS (norber sneider) is quite good in renaming.

But he is a master coder !! I am not very good in python, python is not my style.

it's from self.s.feedrate (if feedrate status exists... check by man page)

Jes, it exists : . linuxcnc.stat attributes => feedrate (returns float) - current feedrate override.

Why override? Did we ask for this? The comment is not so carefully made for "override".

source is then self status channel.

The self.status.feedrate command will work also in Gmocappy source code

Multiple (re)definition's of this can be done in the same source file i think without concequences.

s = linuxcnc.stat() # create a connection to the status channel

s.poll() # get current values

To add in the github section of the linuxcnc readme file :

------------------------------------------------------------------------------

6) Coding Style

===============

Developers shall use the coding style rules in the CodingStyle.txt file.

------------------------------------------------------------------------------Source : github.com/paulscherrerinstitute/ecmaster

Attachments:

Please Log in or Create an account to join the conversation.