- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Configuring Plasmac - a complete THC/plasma config for any hardware

Configuring Plasmac - a complete THC/plasma config for any hardware

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

18 Apr 2019 22:06 - 07 Jul 2019 08:11 #131198

by rodw

Configuring Plasmac - a complete THC/plasma config for any hardware was created by rodw

These instructions are no longer necessary becasue plasmac is now part of master branch (v2.9) and 2.8 branch (which does not include the reverse run code).

The plasmac manual is now available here: linuxcnc.org/docs/devel/html/plasma/plasmac-user-guide.html

Only read on if you would like to install from source but instead, just install master branch from source as plasmac is now included.

This configuration will allow installation of a full featured Plasma control using LInuxcnc for any hardware or any THC:

Any Hardware: Parallel port / Mesa /your hardware. You name it

Any THC: Mesa THCAD plasma voltage reader internal to Linuxcnc, Proma 150 or any other external THC with UP/Down signals

One day this will become part of the mainstream distribution but for now there is a bit of work to get it going but it will be worth it as this will rival any commercial software on the market!

Join myself Tommylight, Islander261 and others who have thrown out hundreds if not thousands of hours of our own development effort to get behind the Plasmac config developed by master coder PhillC who has picked the eyes out of the work we've done and put it all together into a complete cohesive simple to install config on several of your favourite LinuxCNC GUI interfaces,

So lets get started!

See this thread for the development of this system:

forum.linuxcnc.org/plasma-laser/35449-another-plasma-component

This post will get you up and running with the plasmac simulator and a further post will document my experience getting it to run on a live machine.

The first step is to be able to install linuxcnc master branch from source. Really this is pretty easy once you get all of the dependencies installed. The process is described in the docs here:

linuxcnc.org/docs/devel/html/code/building-linuxcnc.html

Its been quite a few months since I have built my system from source so i found I got an error about yapps being missing. I guess it must have been added since I last compiled. This command fixed it

If you are starting from scratch, thefabricator03 says, this is a useful list of dependencies

You should be able to install all of these with the onecommand if you include them all in the one line

We are really only doing this so we can confirm that everything is working. If you run into problems up until this point, please ask elsewhere on the forum as building linuxcnc is out of scope of this thread.

So then it is just a matter of following these commands which will install Phills Plasmac branch into a folder called ~/plasmac (where the ~ symbol is linux shorthand for your home directory).

Lets get going!

If you have got this far, you can ignore this step as if you have installed master branch you have a copy of Plasmac already installed on your PC, but if you wish to install from the master branch source, read on

From a terminal window opened in your home directory (~). Note in this example my machine name iis plasma and my user name is also plasma!

Thats all there is to it except for the bit where I went and got a coffee while make was churning away!

So this will install the sims Phill has built and you can drill down into one of the many example plasmac configs for say axis GUI.

Then run it!

So we are using rin in place. there is no deb install nor do we want one with a developmental branch like this one. To run linuxcnc, open a new terminal window and type the last two lines.

note that if you leave the window open, you only ever need to run the rip-environment script once

The plasmac manual is now available here: linuxcnc.org/docs/devel/html/plasma/plasmac-user-guide.html

Only read on if you would like to install from source but instead, just install master branch from source as plasmac is now included.

This configuration will allow installation of a full featured Plasma control using LInuxcnc for any hardware or any THC:

Any Hardware: Parallel port / Mesa /your hardware. You name it

Any THC: Mesa THCAD plasma voltage reader internal to Linuxcnc, Proma 150 or any other external THC with UP/Down signals

One day this will become part of the mainstream distribution but for now there is a bit of work to get it going but it will be worth it as this will rival any commercial software on the market!

Join myself Tommylight, Islander261 and others who have thrown out hundreds if not thousands of hours of our own development effort to get behind the Plasmac config developed by master coder PhillC who has picked the eyes out of the work we've done and put it all together into a complete cohesive simple to install config on several of your favourite LinuxCNC GUI interfaces,

So lets get started!

See this thread for the development of this system:

forum.linuxcnc.org/plasma-laser/35449-another-plasma-component

This post will get you up and running with the plasmac simulator and a further post will document my experience getting it to run on a live machine.

The first step is to be able to install linuxcnc master branch from source. Really this is pretty easy once you get all of the dependencies installed. The process is described in the docs here:

linuxcnc.org/docs/devel/html/code/building-linuxcnc.html

Its been quite a few months since I have built my system from source so i found I got an error about yapps being missing. I guess it must have been added since I last compiled. This command fixed it

plasma@plasma ~ $ sudo apt_get install yapps2If you are starting from scratch, thefabricator03 says, this is a useful list of dependencies

libudev-dev

libmodbus-dev

libusb-1.0-0-dev

libgtk2.0-dev

yapps2

Intltool

tcl-dev

tk-dev

bwidget

libtk-img

tclx

libreadline-gplv2-dev

python-tk

libboost-python-dev

freeglut3-dev

libxmu-dev

python-glade2

python-gnome2

python-gtkglext1

python-gtksourceview2You should be able to install all of these with the one

sudo apt-get install ...We are really only doing this so we can confirm that everything is working. If you run into problems up until this point, please ask elsewhere on the forum as building linuxcnc is out of scope of this thread.

So then it is just a matter of following these commands which will install Phills Plasmac branch into a folder called ~/plasmac (where the ~ symbol is linux shorthand for your home directory).

Lets get going!

If you have got this far, you can ignore this step as if you have installed master branch you have a copy of Plasmac already installed on your PC, but if you wish to install from the master branch source, read on

From a terminal window opened in your home directory (~). Note in this example my machine name iis plasma and my user name is also plasma!

plasma@plasma ~ $ git clone https://github.com//phillc54/linuxcnc-plasmac plasmac

plasma@plasma ~ $ cd plasmac/src

plasma@plasma ~/plasmac/src $ ./autogen.sh

plasma@plasma ~/plasmac/src $ ./configure --with-realtime=uspace

plasma@plasma ~ $ make

plasma@plasma ~/plasmac/src $ sudo make setuid

[sudo] password for plasma:

plasma@plasma ~/plasmac/src $cd ..

plasma@plasma ~/plasmac $

plasma@plasma ~/plasmac $ . ./scripts/rip-environment

plasma@plasma ~/plasmac $ linuxcncThats all there is to it except for the bit where I went and got a coffee while make was churning away!

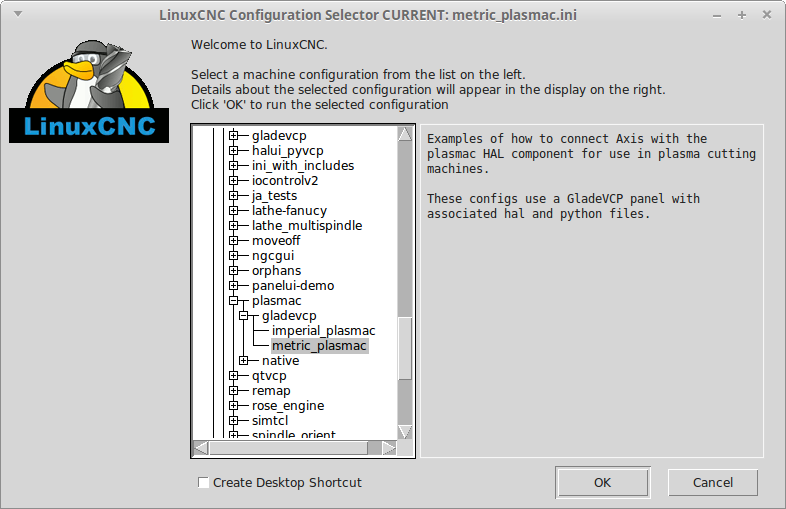

So this will install the sims Phill has built and you can drill down into one of the many example plasmac configs for say axis GUI.

Then run it!

So we are using rin in place. there is no deb install nor do we want one with a developmental branch like this one. To run linuxcnc, open a new terminal window and type the last two lines.

plasma@plasma ~/plasmac $ . ./scripts/rip-environment

plasma@plasma ~/plasmac $ linuxcncnote that if you leave the window open, you only ever need to run the rip-environment script once

Attachments:

Last edit: 07 Jul 2019 08:11 by rodw.

The following user(s) said Thank You: chimeno, tommylight, Clive S, Plasmaguy, dvn4life1972

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

18 Apr 2019 22:07 - 11 May 2019 20:50 #131199

by rodw

Replied by rodw on topic Installing PLASMAC - Another Plasma Component

Ok, this post might grow a bit but lets start getting it onto real hardware. At this point, I'm going to assume you have a basic working config on master branch (V2.8) that gives basic XYZ movement.

If you have your machine set up on an earlier version of Linuxcnc, you have a bit more work to do as there are significant differences in configuration of the machine between V 2.7 to V 2.8. There is a conversion program that should sense you've upgraded when you first run your old config. I have never run v 2.7 so can't really guide you. If all else fails, rebuild a working config using stepconf or pncconf and make sure it works before proceeding.

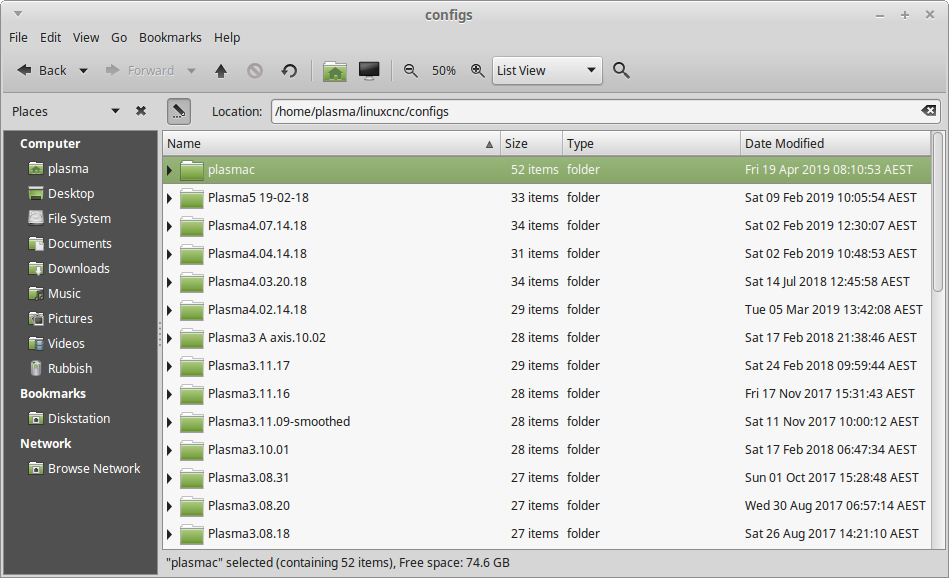

Assuming you want to use the Gmoccapy SIM as a base, open a file browser window and navigate to

Right click on the plasmac folder and select copy.

So then navigate to the ~/linuxcnc/configs folder and paste it in.

So now if you rerun linuxcnc, the chooser will show you the plasmac machine under the My Configurations Tree. Sweet! now we just need to edit the config files to insert the real config for our hardware and we'll be away. As a first start its useful to copy your existing config files into this new folder so we don't muck up any existing configs

If you have your machine set up on an earlier version of Linuxcnc, you have a bit more work to do as there are significant differences in configuration of the machine between V 2.7 to V 2.8. There is a conversion program that should sense you've upgraded when you first run your old config. I have never run v 2.7 so can't really guide you. If all else fails, rebuild a working config using stepconf or pncconf and make sure it works before proceeding.

Assuming you want to use the Gmoccapy SIM as a base, open a file browser window and navigate to

/home/plasma/plasmac/configs/sim/gmoccapy/Right click on the plasmac folder and select copy.

So then navigate to the ~/linuxcnc/configs folder and paste it in.

So now if you rerun linuxcnc, the chooser will show you the plasmac machine under the My Configurations Tree. Sweet! now we just need to edit the config files to insert the real config for our hardware and we'll be away. As a first start its useful to copy your existing config files into this new folder so we don't muck up any existing configs

Last edit: 11 May 2019 20:50 by rodw.

The following user(s) said Thank You: billykid, chimeno, tommylight, CNCFred

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

18 Apr 2019 22:11 - 10 May 2019 04:49 #131200

by rodw

Replied by rodw on topic Configuring Plasmac - a complete THC/plasma config for any hardware

So from here, I had a bit of a look in the plasmac folder and decided imperial units are irrelevant for me so I deleted any imperial files and checked the metric config still opened. It Did!.

So then I made a copy of the default ini file and renamed it to spaceship_plasma.ini once again checking I could open it and I could!

So the next thing to do is to carefully review your existing working ini file and paste in the relevant sections from my existing known good config replacing what was provided. So now all of my step timings etc should be perfect. Once again I checked, it would open and it did!

So now all I have to do is fold in the specific config form my machine into the plasmac hal files. Not looking forward to that as I have a lot in there!

CONTINUED: Well it was pretty painless in the end. If you are using a Mesa THCAD board, I found there were some bugs in the plasmac configuation screen which I'm sure Phill will fix but n the meantime, you might be better off using this component I wrote previously with scaling of 1.0 and an offset of 0. forum.linuxcnc.org/plasma-laser/32585-scalethcad-component Thats what I did.

Set the mode in the ini file to the one that suits you. If you are using a Mesa THCAD card, use mode 1.

Delete or comment out these lines

Swap the comments around in this block. You need to comment out the TCL file and uncomment the line with machine.hal on it so your ini file knows how to load your hal file.

Also its worth discussing these settings for the Z axis in the ini filewhich are specific to the external offsets Plasmac uses. I forgot to mention them earlier because I've been using them for so long.So MAX_VELOCITY and MAX_ACCELERATION should be double what your machine is capable of.

External offsets was designed that a percentage of velocity and acceleration was devoted to external offsets on the assumption that offsets would be applied while motions was occurring. In the case of plasma standard Z axis motion and external offset motion are mutually exclusive. You are either jogging around or you are cutting. So we want to devote 100% of velocity and acceleration to the Z axis while its under THC control. So by doubling your machine settings and applying a ratio of 0.5 (50%) we actually trick external offsets into using 100% of the axis machine settings for THC control. Cool hey! It did my head in working that out the first time.

Here is my completed ini file for guidance.

Create a new file in your config called machine.hal

Copy all of your basic configuration stuff from your existing working file into this file and save it.

Here is a basic example of what your machine.hal might look like (note this file will need renaming).

This file was prepared by Islander261 for JTknives later in this thread. (My hal file has a lot more in it so it would only confuse you if I shared it).

Edit plasmac.hal and add your specific pins and signals. I think with the benefit of hindsight, this procedure should be changed and the custom part should be moved into another hal file that is loaded after plasmac.hal. This will make life easier on upgrades. I will come back and revise these instructions once I have done it.

See if you can open the config in Linuxcnc and note any errors.

I found I was already using some of the signals so I had a few errors so I edited the plasmac defaults to use my already defined signals until eventually it opened. Thats it, you are done

Actually a lot easier than I expected!

So then I made a copy of the default ini file and renamed it to spaceship_plasma.ini once again checking I could open it and I could!

So the next thing to do is to carefully review your existing working ini file and paste in the relevant sections from my existing known good config replacing what was provided. So now all of my step timings etc should be perfect. Once again I checked, it would open and it did!

So now all I have to do is fold in the specific config form my machine into the plasmac hal files. Not looking forward to that as I have a lot in there!

CONTINUED: Well it was pretty painless in the end. If you are using a Mesa THCAD board, I found there were some bugs in the plasmac configuation screen which I'm sure Phill will fix but n the meantime, you might be better off using this component I wrote previously with scaling of 1.0 and an offset of 0. forum.linuxcnc.org/plasma-laser/32585-scalethcad-component Thats what I did.

Set the mode in the ini file to the one that suits you. If you are using a Mesa THCAD card, use mode 1.

# sets the operating mode, if not specified the default is 0

# 0 = use arc-voltage-in for arcOK and THC (no need to connect arc-ok-in, move-up-in and move-down-in)

# 1 = use arc-ok-in for arcOK and arc-voltage-in for THC (no need to connect move-up-in and move-down-in)

# 2 = use arc-ok-in for arcOK and move-down-in + move-up-in for THC (no need to connect arc-voltage-in)

MODE = 1

# this section only required if using the sim testing panel

[APPLICATIONS]

DELAY = 3

APP = ./test/plasmac_test.pySwap the comments around in this block. You need to comment out the TCL file and uncomment the line with machine.hal on it so your ini file knows how to load your hal file.

#HALFILE = machine.hal

HALFILE = LIB:basic_sim.tclAlso its worth discussing these settings for the Z axis in the ini filewhich are specific to the external offsets Plasmac uses. I forgot to mention them earlier because I've been using them for so long.

[AXIS_Z]

OFFSET_AV_RATIO = 0.5

MAX_VELOCITY = 120

MAX_ACCELERATION = 1400External offsets was designed that a percentage of velocity and acceleration was devoted to external offsets on the assumption that offsets would be applied while motions was occurring. In the case of plasma standard Z axis motion and external offset motion are mutually exclusive. You are either jogging around or you are cutting. So we want to devote 100% of velocity and acceleration to the Z axis while its under THC control. So by doubling your machine settings and applying a ratio of 0.5 (50%) we actually trick external offsets into using 100% of the axis machine settings for THC control. Cool hey! It did my head in working that out the first time.

Here is my completed ini file for guidance.

Create a new file in your config called machine.hal

Copy all of your basic configuration stuff from your existing working file into this file and save it.

Here is a basic example of what your machine.hal might look like (note this file will need renaming).

This file was prepared by Islander261 for JTknives later in this thread. (My hal file has a lot more in it so it would only confuse you if I shared it).

Edit plasmac.hal and add your specific pins and signals. I think with the benefit of hindsight, this procedure should be changed and the custom part should be moved into another hal file that is loaded after plasmac.hal. This will make life easier on upgrades. I will come back and revise these instructions once I have done it.

See if you can open the config in Linuxcnc and note any errors.

I found I was already using some of the signals so I had a few errors so I edited the plasmac defaults to use my already defined signals until eventually it opened. Thats it, you are done

Actually a lot easier than I expected!

Attachments:

Last edit: 10 May 2019 04:49 by rodw. Reason: added example machine.hal

The following user(s) said Thank You: Clive S, CNCFred

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

19 Apr 2019 06:50 #131223

by pl7i92

Replied by pl7i92 on topic Installing PLASMAC - Another Plasma Component

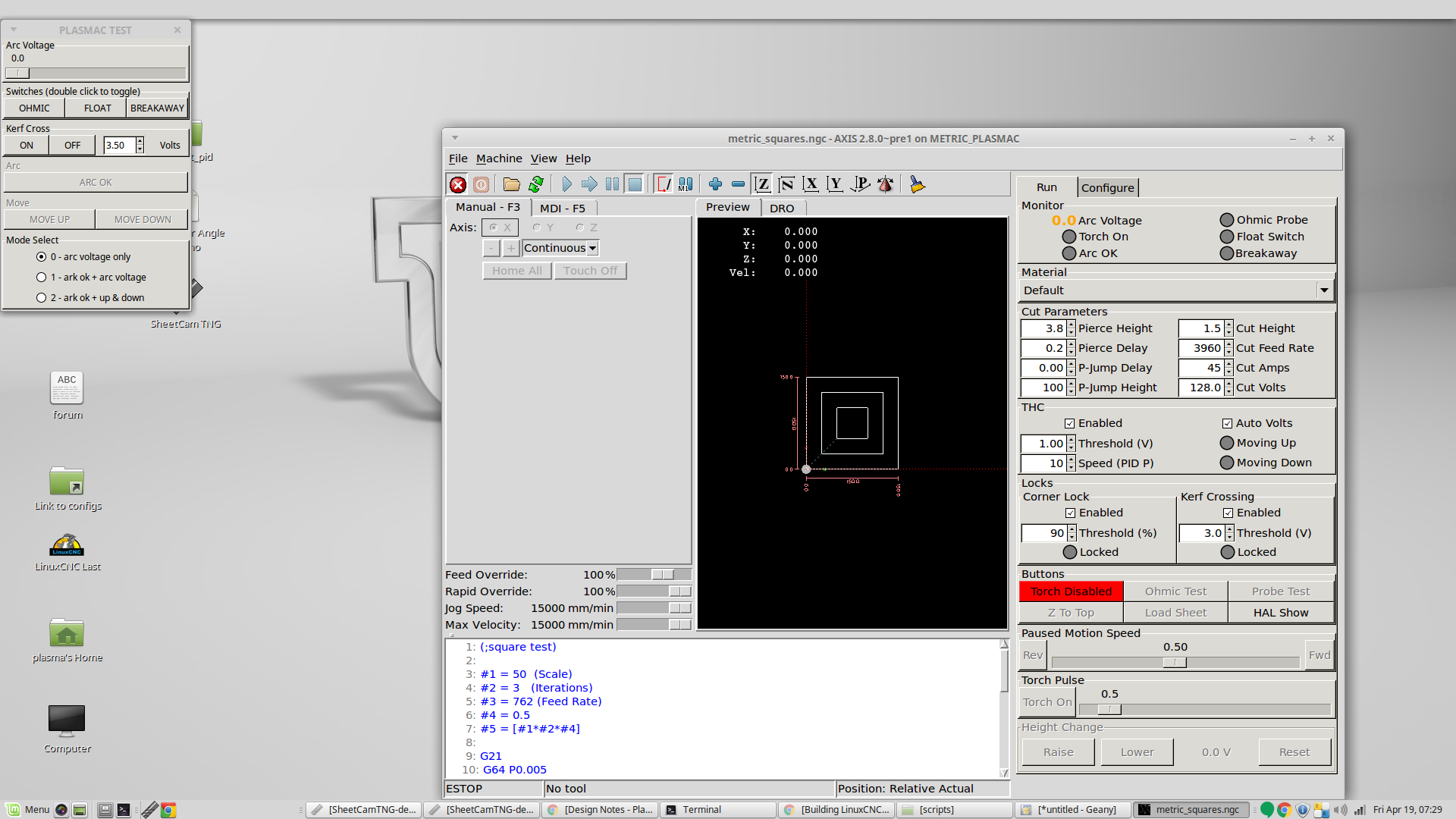

information overload

all infos on the system displayed

Question does this component interfere standard G-code

so no height torch height pierce height needs to be in

all infos on the system displayed

Question does this component interfere standard G-code

so no height torch height pierce height needs to be in

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

19 Apr 2019 07:28 #131227

by rodw

Yes thats right. There are several modes you can select from but all the probing happen with a M3 (not that I've got that far yet). It also includes PID based torch height control and auto torch voltage sampling. Phill has incorporated everything people have discovered over the lastcople of years into one repo. A few people have run into problems trying to get this up and running (mainly because it requires compiling a private clone of LinuxCNC) so I decided I'd write a bit of a guide on how to install it while I was installing it on my machine. I have not cut anything with it yet. Its actually been put together very well and is the simplest plasma config I've seen to get up and running.

Replied by rodw on topic Installing PLASMAC - Another Plasma Component

Question does this component interfere standard G-code

so no height torch height pierce height needs to be in

Yes thats right. There are several modes you can select from but all the probing happen with a M3 (not that I've got that far yet). It also includes PID based torch height control and auto torch voltage sampling. Phill has incorporated everything people have discovered over the lastcople of years into one repo. A few people have run into problems trying to get this up and running (mainly because it requires compiling a private clone of LinuxCNC) so I decided I'd write a bit of a guide on how to install it while I was installing it on my machine. I have not cut anything with it yet. Its actually been put together very well and is the simplest plasma config I've seen to get up and running.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

22 Apr 2019 08:31 - 22 Apr 2019 10:25 #131473

by rodw

Replied by rodw on topic Installing PLASMAC - Another Plasma Component

Becasue plasmac is an experimental branch and subject to continual improvements, you'll need to know how to update your config. This is really easy. This will do the trick.:

This usually takes less than a minute as make only compiles what has changed. git pull will pull down any changed files from git.

Now I found that this did not update my working config on ~/linuxcnc/configs/plasmac

so what I did ir rename this folfer to ~/linuxcnc/configs/plasmac1 and copy the sim folder again to be sure I got everything that had changed.

Then all I had to do is to copy over 4 files. machine.hal, plasmac.hal (only becasue I changed it) my .ini file and my .mat file.

We have not talked about that one but there is a text file ending in.mat that you can edit for all of your cut settings for the materials you cut that will then appear in the drop downs. Editing it will be self explanatory when you open it.

git pull

make

sudo make setuidThis usually takes less than a minute as make only compiles what has changed. git pull will pull down any changed files from git.

Now I found that this did not update my working config on ~/linuxcnc/configs/plasmac

so what I did ir rename this folfer to ~/linuxcnc/configs/plasmac1 and copy the sim folder again to be sure I got everything that had changed.

Then all I had to do is to copy over 4 files. machine.hal, plasmac.hal (only becasue I changed it) my .ini file and my .mat file.

We have not talked about that one but there is a text file ending in.mat that you can edit for all of your cut settings for the materials you cut that will then appear in the drop downs. Editing it will be self explanatory when you open it.

Last edit: 22 Apr 2019 10:25 by rodw.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

22 Apr 2019 10:23 #131480

by pl7i92

Replied by pl7i92 on topic Installing PLASMAC - Another Plasma Component

i will give it a try this year as we build plasma number 5 as huge as the sheets 2500x1500mm cut area

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21364

- Thank you received: 7287

22 Apr 2019 12:56 #131499

by tommylight

Open a file browser window, not terminal.

Replied by tommylight on topic Installing PLASMAC - Another Plasma Component

Minor correction:Open a terminal window and navigate to

/home/plasma/linuxcnc/configs

Open a file browser window, not terminal.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

22 Apr 2019 13:04 #131500

by rodw

Tommy, thanks fixed. I Won't go into how long I chased a bug in my hal file today becasue I forgot to addf a component!

Replied by rodw on topic Installing PLASMAC - Another Plasma Component

Minor correction:

Open a file browser window, not terminal.

Tommy, thanks fixed. I Won't go into how long I chased a bug in my hal file today becasue I forgot to addf a component!

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

25 Apr 2019 20:54 #131888

by rodw

Replied by rodw on topic Installing PLASMAC - Another Plasma Component

So now I've used this a bit, I found the most important setting is the probe height. Probe height is measured up from Zmin. You have to make sure that the probe height is above the top surface of the material.

Here is a workflow from Islander261 using plasmac and Gmoccappy.

Here is a workflow from Islander261 using plasmac and Gmoccappy.

Here is my typical work flow as it may help clear things up. Using Gmoccapy in the Plasmac branch.

1.Start terminal session.

2.Set Plasmac RIP environment

3. Start LinuxCNC

4. Pick configuration I want to run

5. Take program out of estop

6. Switch machine on with GUI button

7. Press the Homing button in bottom left corner of GUI

8. Press Home All button in bottom left corner of GUI and wait for homing to finish

9. Press Load Material button on buttons panel and wait for gantry to clear table

10. Place work piece on table and square to table motion using laser crosshairs

11. Jog to work piece origin

12. Press Touch Off button on bottom of GUI (second from left)

13. Press X Set button

14. In popup window set X offset to 0 (should be default choice)

15. Repeat 13 & 14 for Y axis

16. Press return button on bottom right of GUI to clear Touch Off Tab, you should see G54 offset label displayed in DRO

17. Check settings

18. Load program

19. Enable Torch

20. Start program

The following user(s) said Thank You: phillc54, tommylight

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Configuring Plasmac - a complete THC/plasma config for any hardware

Time to create page: 0.349 seconds