Downdraft design questions

- Himarc3D

-

- Offline

- Premium Member

-

- Posts: 120

- Thank you received: 49

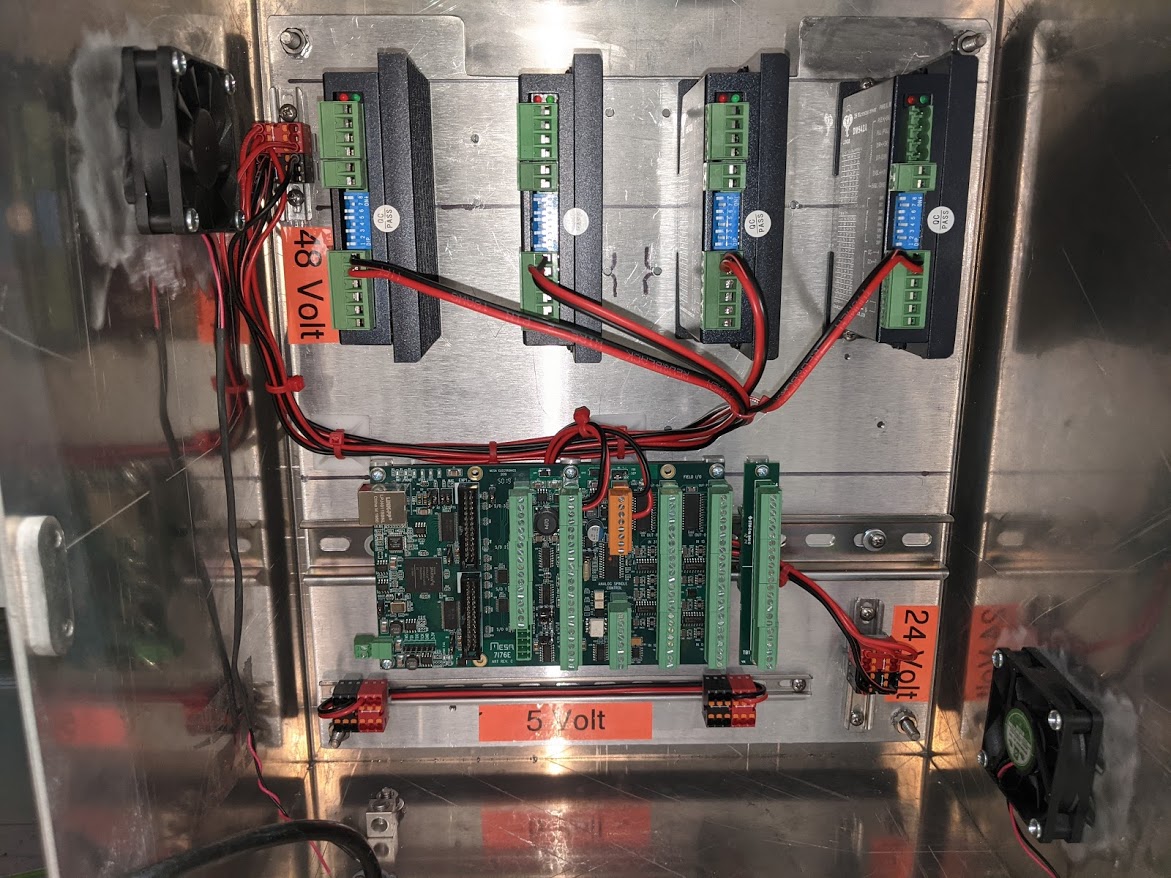

The Aciera advice is one of the points to pay attention when design.

2. Avoid stacking heat producing components one above the other, and allow an unrestricted flow of air behind components whenever possible

Avoid this will help in your wire route too

7. Wiring can also affect enclosure temperature. Properly cabling wires and routing bundles along enclosure corners keeps wires from resting on components and helps minimize airflow restriction.

You have small drivers 80W and at idle 50W, DM542?

I dont think you even need the fans, the big hole for wire i think take off the fan purpose, fan tend to fail and if the design need it to run its something to consider, its okay to run with open door until fix the fan?

If you paint your box will help a lot to reduce heat too.

Check this calculator

www.punchlistzero.com/control-panel-heat...sipation-calculator/

The quotes are from here;

thermal-edge.com/thermal-management-guid...voiding-overheating/

Another calculator;

thermal-edge.com/enclosure-temperature-management-calculator/

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

- Posts: 4704

- Thank you received: 1443

Please Log in or Create an account to join the conversation.

- Himarc3D

-

- Offline

- Premium Member

-

- Posts: 120

- Thank you received: 49

In my mind the question is how hot they get to install whatever the position just pay attention to the heatsink side and proper space to air flow

My motors i follow the manufacture instructions i dont runt it over 80C (68C).

Some drivers are din mount so you cant install horizontal or some models have fan and you need to pay attention to air flow direction.

I have yasukawa sigma driver (servo) and its up mounting and i think its because have fan up side.

I dont know the driver spec here but i guess its the same the oriental about orientation and looks like he have 40mm to 50mm between the driver

www.orientalmotor.com/products/pdfs/opmanuals/HM-60128-7E.pdf

www.orientalmotor.com/products/pdfs/Step...ionBIntro_B2-B42.pdf.

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 384

- Thank you received: 106

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21370

- Thank you received: 7288

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 384

- Thank you received: 106

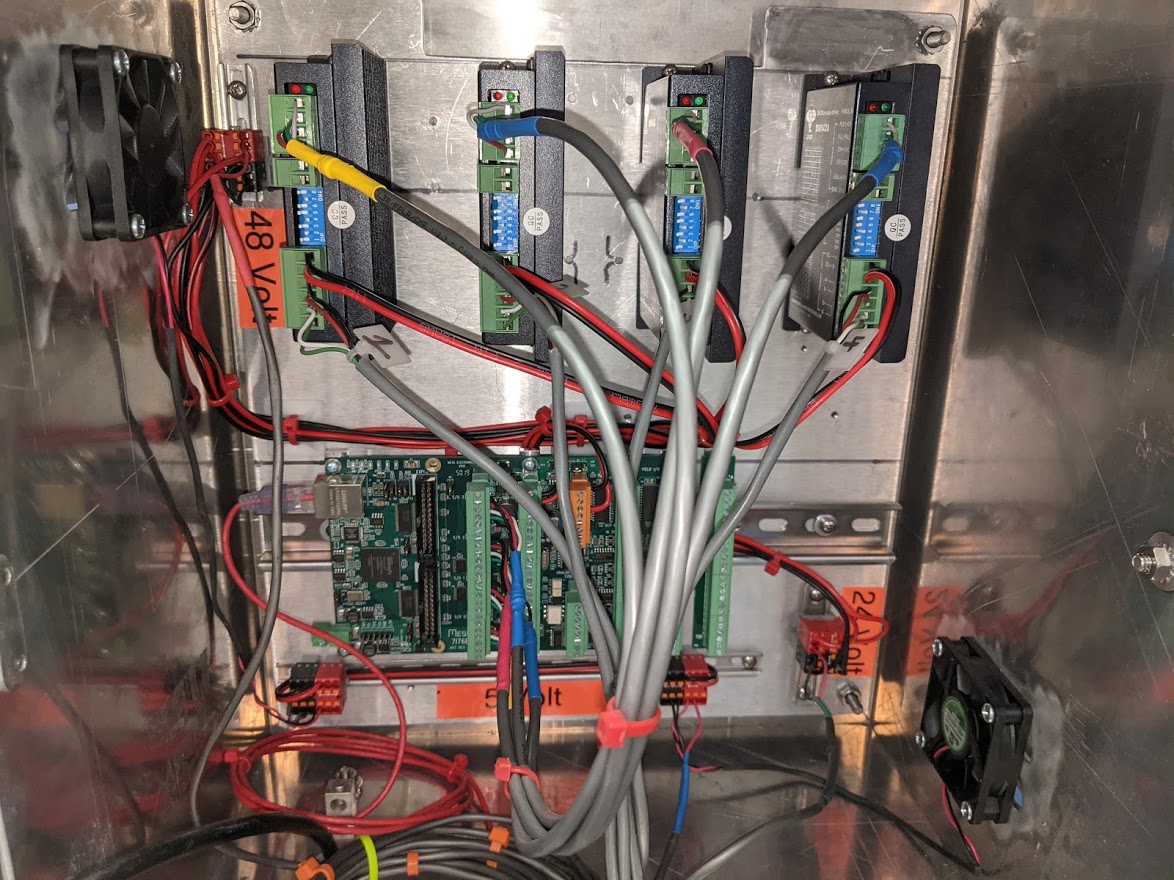

Neat !

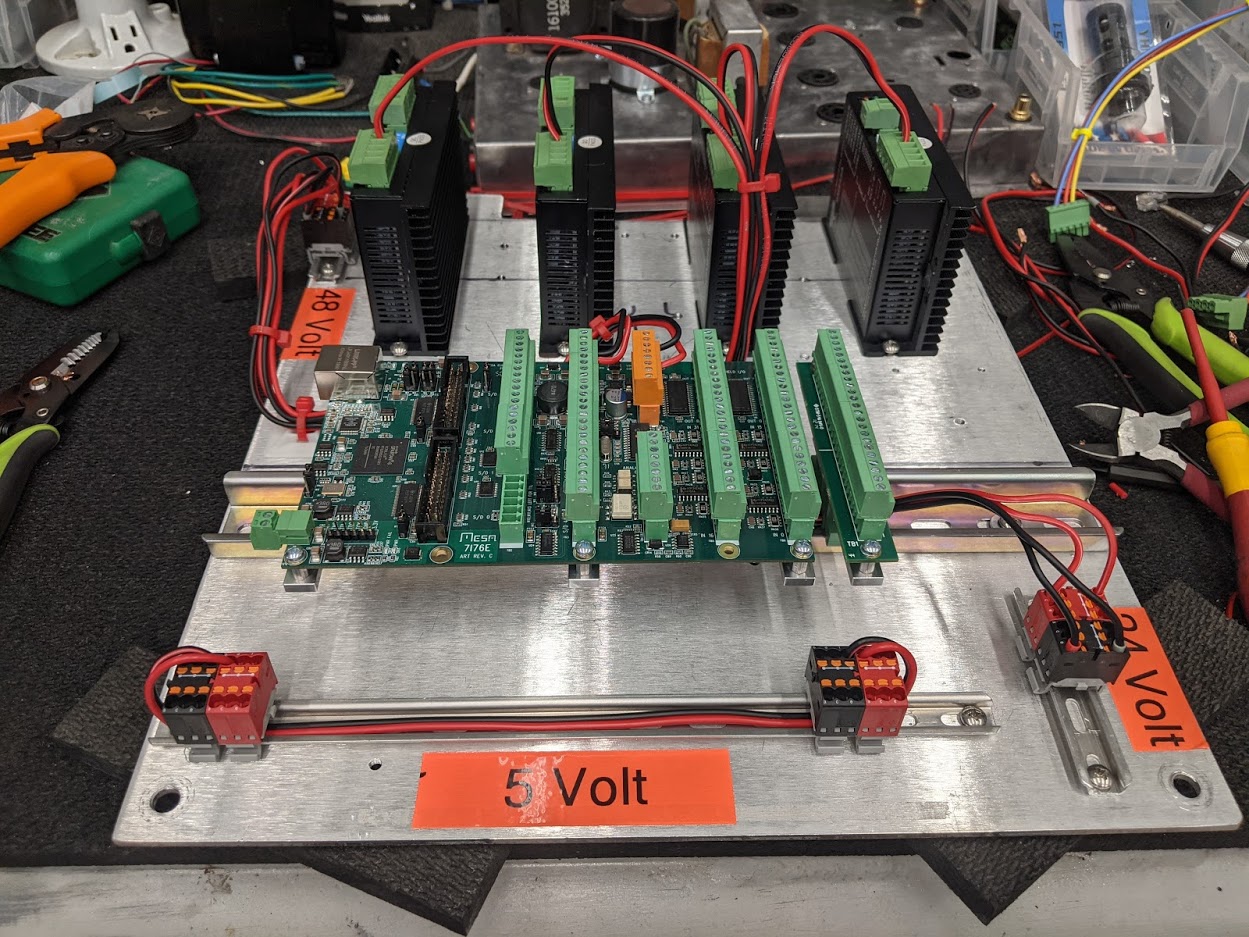

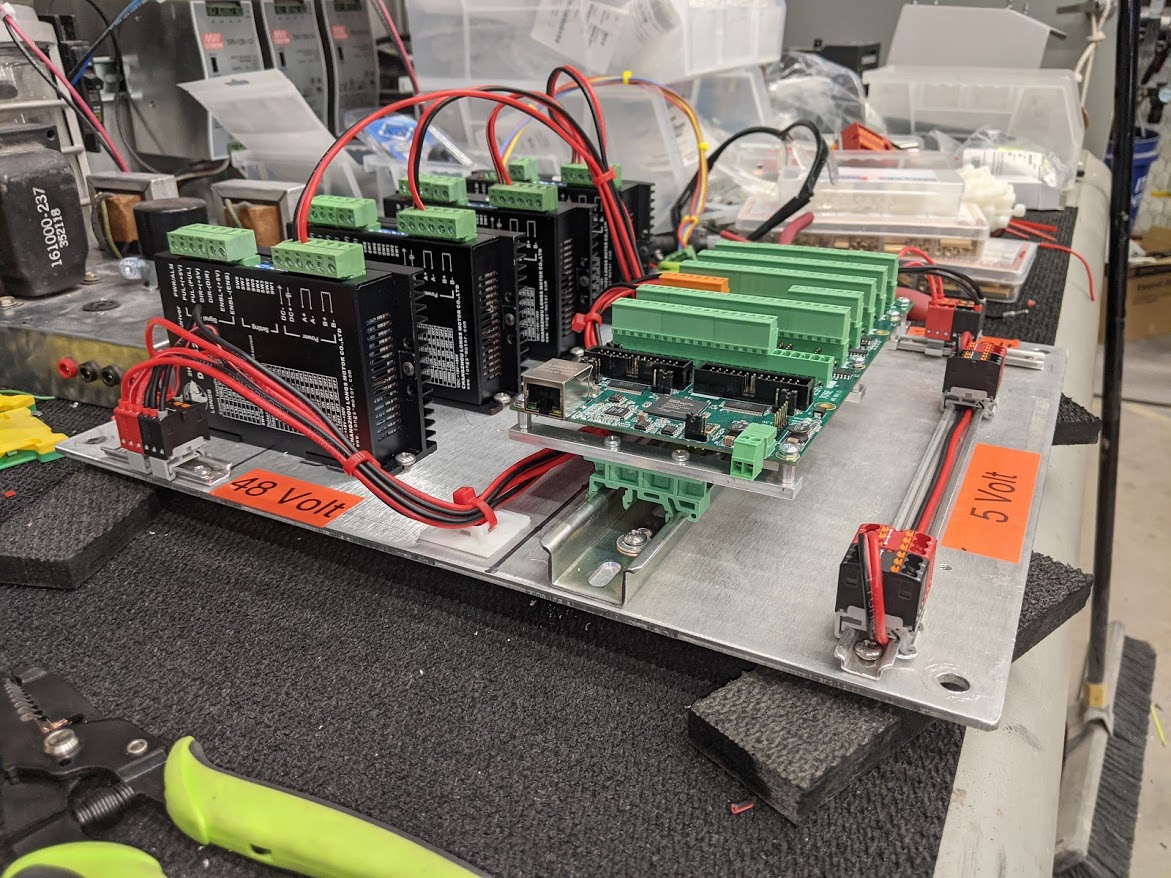

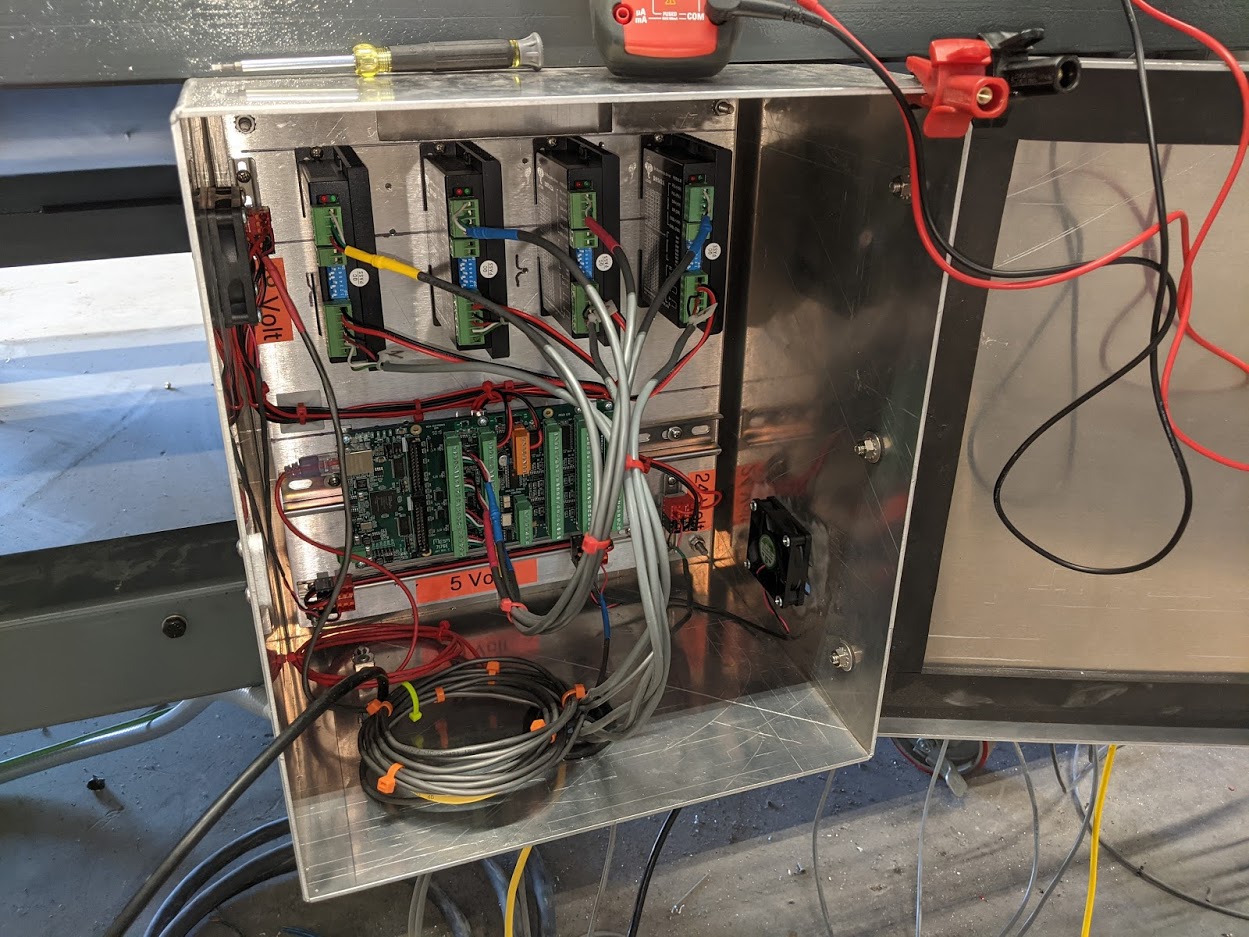

Thanks! I just got the motors moving! I need to land the home switches and do some calibration... then I will have to 'hit the books' on Plasmac.

I will clean up the wiring a bit more after I get everything working.

I am not sure exactly when I should integrate the pneumatic actuator solenoids, should that be done before I get into Plasmac, or after?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21370

- Thank you received: 7288

4X0.75 is the absolute minimum for small Nema17 motors that i use, for anything bigger i use 4x2.5mm2.

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 384

- Thank you received: 106

Motor wires seem very thin, that will limit the torque and speed by quite a margin.

4X0.75 is the absolute minimum for small Nema17 motors that i use, for anything bigger i use 4x2.5mm2.

Interesting. These motors came prewired from the vendor of my previous electronics package. I just checked, these motors are wired with 18AWG, you would use 14AWG? What wire type/make do you use? Thx

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21370

- Thank you received: 7288

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 384

- Thank you received: 106

I have a ground rod outside my building that is isolated from everything else. There is an insulated wire that connects the ground rod to the table, via a threaded bolt on the table frame. At that bolt there is a another, smaller wire that connects to the gantry.

The plasma unit is always connected to the plate itself when I am cutting.

Is that sufficient?

Please Log in or Create an account to join the conversation.