Fusion 360 post processor file for Plamac

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

20 Feb 2020 22:49 #158071

by phillc54

Stefan is trialling it, if he reports that it went well I will put it in the PlasmaC section.

Replied by phillc54 on topic Fusion 360 post processor file for Plamac

I have not looked at the post processors for Sheetcam that have been posted lately so I am hoping Phil will go ahead and post the one he has.

Stefan is trialling it, if he reports that it went well I will put it in the PlasmaC section.

The following user(s) said Thank You: docwelch

Please Log in or Create an account to join the conversation.

- CFE

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 35

21 Feb 2020 08:02 #158095

by CFE

Replied by CFE on topic Fusion 360 post processor file for Plamac

Thanks Steven, i will look into the sheetcam going on your advise. I was hoping to limit the amount of programs and steps needed to complete a task from start to finish. We use Gibbs cam to program our mill and lathes and fusion has been filling the gap with design and sheetmetal. If the Fusion cam worked out for the plasma it was just a bonus!! Thankyou again for your advise on this forum this far i hope you manage to get something to work efficiently for you, before you start the Job with 200 holes!!!!

Please Log in or Create an account to join the conversation.

- docwelch

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 25

02 Mar 2020 21:37 #159037

by docwelch

Replied by docwelch on topic Fusion 360 post processor file for Plamac

I got a working solution to the circles being broken into many arcs problem over on the Fusion360 forum from Bob Schultz. I have incorporated that solution into my Fusion360 post processor. I will post this over in the PlasmaC Post Processors topic that Phil recently started.

Steven

Steven

The following user(s) said Thank You: phillc54, tommylight, rodw

Please Log in or Create an account to join the conversation.

- CFE

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 35

03 Mar 2020 21:34 #159112

by CFE

Replied by CFE on topic Fusion 360 post processor file for Plamac

Thankyou again Steven very much appreciated that you have shared the post processor. Your solution will make a big difference, having managed to incorporate the small hole processing and center punch mark features and by taking the time to produce a manual.

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

08 May 2020 18:27 #167069

by dvn4life1972

Replied by dvn4life1972 on topic Fusion 360 post processor file for Plamac

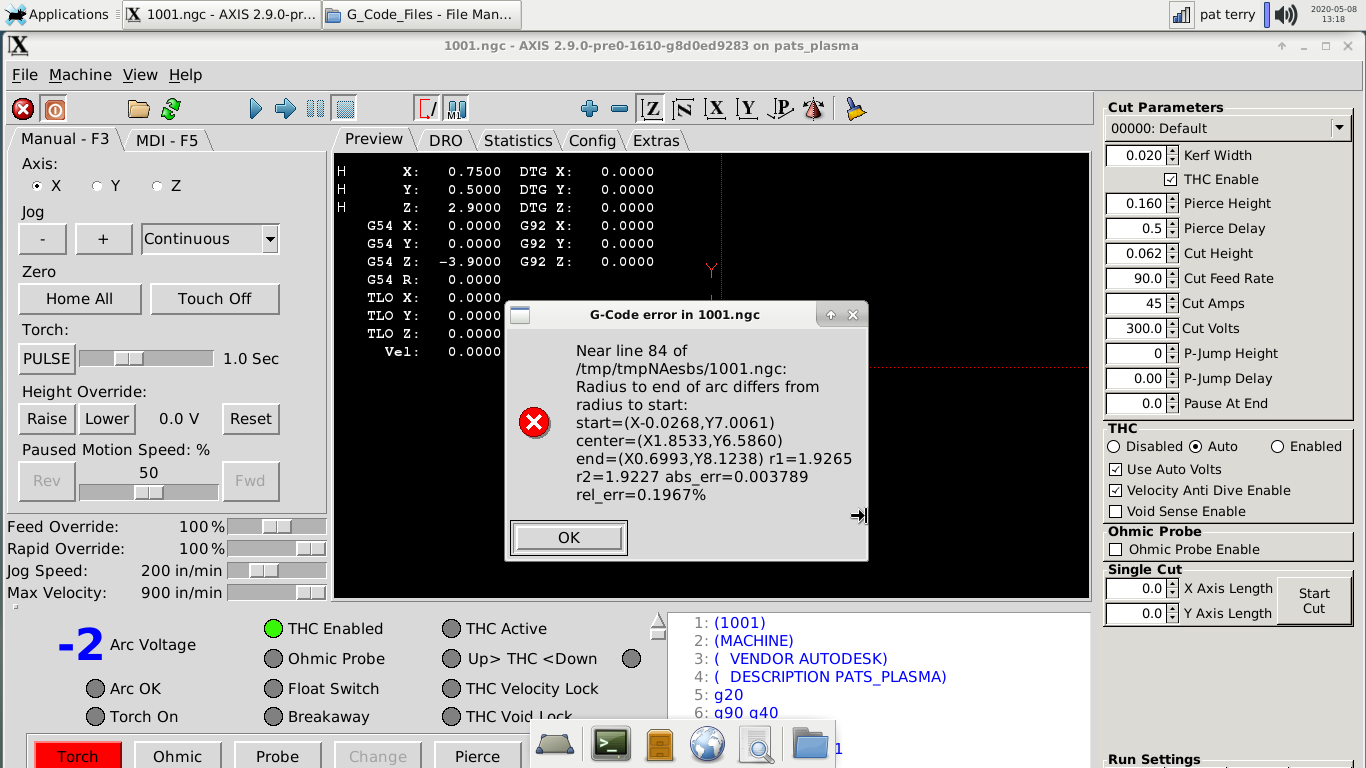

I appreciate the time and effort put into this pp. I couldn't dream of making an attempt at it. I've tried to use it several times, and I keep getting the same type of error at the machine when I load the gcode file. I've attached a screenshot of the error message as well as attached the gcode file itself.

Pat

Pat

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

08 May 2020 23:32 #167088

by phillc54

Replied by phillc54 on topic Fusion 360 post processor file for Plamac

Maybe it needs some more digits of precision for the calculations.

You could try changing CENTER_ARC_RADIUS_TOLERANCE_INCH to say 0.004

linuxcnc.org/docs/2.8/html/config/ini-co...l#gcode:ini-features

You could try changing CENTER_ARC_RADIUS_TOLERANCE_INCH to say 0.004

linuxcnc.org/docs/2.8/html/config/ini-co...l#gcode:ini-features

The following user(s) said Thank You: dvn4life1972

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

30 Jun 2020 02:56 #173168

by islander261

Replied by islander261 on topic Fusion 360 post processor file for Plamac

Please bear with me as I am not skilled at using Fusion 360 and the CAM features. I am also not skilled in describing the geometry of Cartesian moves.

I needed to make a piece of equipment that required solid modeling to get all the parts right. So I built up a model in Fusion 360 with little effort ( I am an old ProE hand). Then I went to CAM several of the sheet steel parts to cut out with the plasma cutter using PlasmaC for the control. I used the PlasmaC post processor for Fusion 360 posted at the top of the topics. It took a bit of work to get everything setup and going but in the end I was able to get the models posted without any reported errors. Upon loading the Gcode into Plasmac I was greeted with errors on some of the arc moves. While the start and end points of the arcs were correct the posted I and J values were not on the blocks that error-ed out. The first thing I did notice was that the posted precision was rather excessive for imperial units, I reduced the posted precision to 4 places for imperial units with no change in the reported errors on loading. Because these are simple rectilinear parts I was able to manually fix the code to produce the parts.

The errors always occurred with two types of moves. A G2 (clockwise move) with the arc in the 4th quadrant and a G3 ( counter clockwise move) with the arc in the 2nd quadrant. The errors are very repeatable with minor geometry changes producing the same errors. So for now it is back to Inkscape and SheetCam for me.

One other thing, is there a way in Fusion 360 to do nesting? I like to cut a whole sheet of mixed parts at a time. I know how to do it manually by using work piece offsets but that isn't nice and graphically easy to do.

John

I needed to make a piece of equipment that required solid modeling to get all the parts right. So I built up a model in Fusion 360 with little effort ( I am an old ProE hand). Then I went to CAM several of the sheet steel parts to cut out with the plasma cutter using PlasmaC for the control. I used the PlasmaC post processor for Fusion 360 posted at the top of the topics. It took a bit of work to get everything setup and going but in the end I was able to get the models posted without any reported errors. Upon loading the Gcode into Plasmac I was greeted with errors on some of the arc moves. While the start and end points of the arcs were correct the posted I and J values were not on the blocks that error-ed out. The first thing I did notice was that the posted precision was rather excessive for imperial units, I reduced the posted precision to 4 places for imperial units with no change in the reported errors on loading. Because these are simple rectilinear parts I was able to manually fix the code to produce the parts.

The errors always occurred with two types of moves. A G2 (clockwise move) with the arc in the 4th quadrant and a G3 ( counter clockwise move) with the arc in the 2nd quadrant. The errors are very repeatable with minor geometry changes producing the same errors. So for now it is back to Inkscape and SheetCam for me.

One other thing, is there a way in Fusion 360 to do nesting? I like to cut a whole sheet of mixed parts at a time. I know how to do it manually by using work piece offsets but that isn't nice and graphically easy to do.

John

Please Log in or Create an account to join the conversation.

- CFE

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 35

22 Jul 2020 02:56 #175372

by CFE

Replied by CFE on topic Fusion 360 post processor file for Plamac

In the 'Property' section of the Post Process dialog box in Fusion change the "MergeCircles" value to "NO" this will fix the radius differs issue

The following user(s) said Thank You: dvn4life1972

Please Log in or Create an account to join the conversation.

- turbodude

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 3

22 Sep 2020 11:23 #183273

by turbodude

Replied by turbodude on topic Fusion 360 post processor file for Plamac

I am just playing with the Fusion 360 PlasmaC post processor now. Is the intention that you need to create a tool in F360 that has zero kerf width so that the GCode is created with movements that are "on the line" and then PlasmaC adds offset based on its chosen kerf width??? I have tried with an existing plasma tool in Fusion 360 with a kerf width of 1.3mm and then posting with the PlasmaC PP and the GCode definitely contains the offset. I assume PlasmaC will then add more offset based on its kerf width. Is this correct?

Please Log in or Create an account to join the conversation.

- turbodude

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 3

22 Sep 2020 11:28 #183275

by turbodude

Replied by turbodude on topic Fusion 360 post processor file for Plamac

I just tried & Fusion 360 won't let me set a zero kerf plasma tool. What am I missing???

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.234 seconds