Fusion 360 post processor file for Plamac

- Doug @ Design8Studio.com

-

- Offline

- Premium Member

-

Less

More

- Posts: 131

- Thank you received: 45

20 Jan 2023 09:27 #262465

by Doug @ Design8Studio.com

Replied by Doug @ Design8Studio.com on topic Fusion 360 post processor file for Plamac

Certainly. However the piece of wall art I cut for my first real cut project was very involved, with thousands of lines of code.

I downloaded the free trial and will see how it functions.

I downloaded the free trial and will see how it functions.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

20 Jan 2023 13:00 #262482

by tommylight

Replied by tommylight on topic Fusion 360 post processor file for Plamac

If you have some time, give Inkscape a try, it is very usable for plasma cutting, easy to use and free for Linux and Windows.

I use it and so do all machines i built/worked on, daily.

I have also modified gcodetools.py to output plasmac.feed.rate so the cutting speed in use is from plasmac material table.

I use it and so do all machines i built/worked on, daily.

I have also modified gcodetools.py to output plasmac.feed.rate so the cutting speed in use is from plasmac material table.

Please Log in or Create an account to join the conversation.

- Doug @ Design8Studio.com

-

- Offline

- Premium Member

-

Less

More

- Posts: 131

- Thank you received: 45

20 Jan 2023 21:17 #262523

by Doug @ Design8Studio.com

Replied by Doug @ Design8Studio.com on topic Fusion 360 post processor file for Plamac

That is so cool. I have inkscape, and recently saw here on the site that there is a way to use it to output for plasma cutting. Amazing.

My longtime tool of choice for vector illustration (literally decades of use) is CorelDraw. I have an old copy functioning in a virtual machine that is fire-walled away from any cycle of obsolescence (LOL) or any internet viruses.

For designing sheet parts that are intended to be folded, and then flattening the plan for cutting, I'm pretty impressed with Fusion 360, although learning to use it has been challenging because I was entrenched and skillful in the SketchUp paradigm.

My longtime tool of choice for vector illustration (literally decades of use) is CorelDraw. I have an old copy functioning in a virtual machine that is fire-walled away from any cycle of obsolescence (LOL) or any internet viruses.

For designing sheet parts that are intended to be folded, and then flattening the plan for cutting, I'm pretty impressed with Fusion 360, although learning to use it has been challenging because I was entrenched and skillful in the SketchUp paradigm.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

20 Jan 2023 21:42 #262524

by tommylight

Replied by tommylight on topic Fusion 360 post processor file for Plamac

For parts intended to be folded, have a look at "things made here" on youtube, adding a sharpie to plasma machines makes it very usable.

Please Log in or Create an account to join the conversation.

- Doug @ Design8Studio.com

-

- Offline

- Premium Member

-

Less

More

- Posts: 131

- Thank you received: 45

20 Jan 2023 22:04 #262525

by Doug @ Design8Studio.com

Replied by Doug @ Design8Studio.com on topic Fusion 360 post processor file for Plamac

Yep, I've seen the very video you're talking about, and my plasma tool mount has a place to add a sharpie when needed, and I plan to let my floating Z do a double duty here, in that if the sharpie tip is positioned lower than the plasma tip, the floating Z should allow marking on the metal without the need of a separate spring tensioner mount dedicated just to the pen. My approach is a low-tech solution that is way easier and cheaper to do than the "things made here" hydraulic approach.

Please Log in or Create an account to join the conversation.

- ashesman

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 4

23 Dec 2023 04:53 #288863

by ashesman

Replied by ashesman on topic Fusion 360 post processor file for Plamac

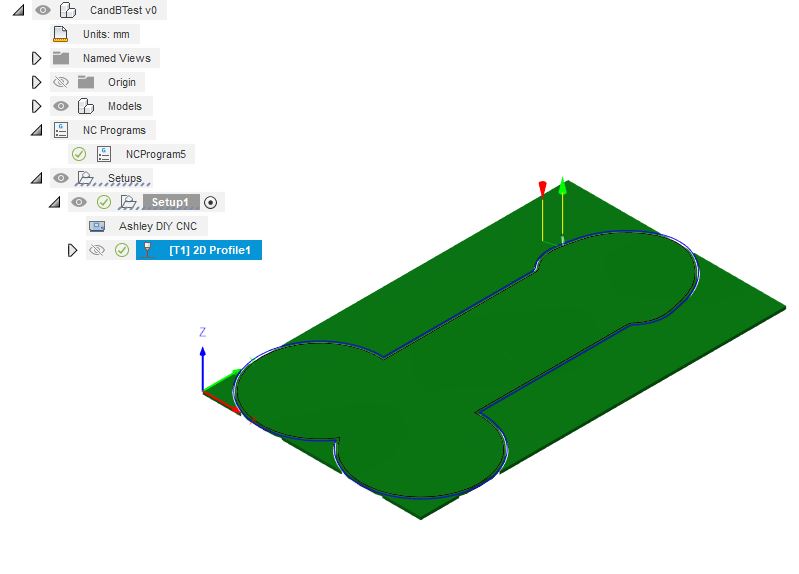

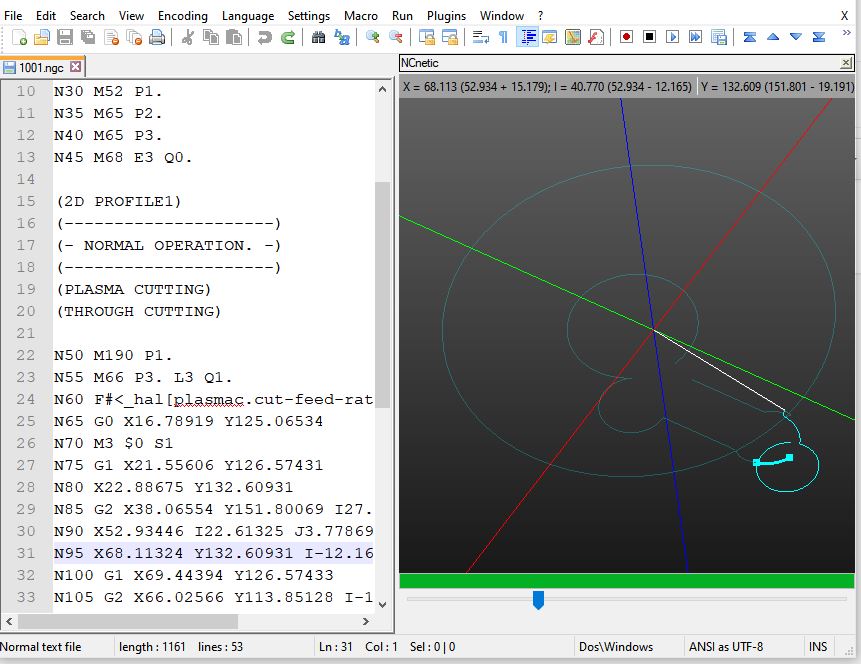

I used the F360 post processor for the first time today. I got it from forum.linuxcnc.org/plasmac/38438-plasmac-post-processors#159042. Seemed to all work fine until I tried to run the generated g code in Plasmac (qtPlasmac). I got some error messages about arcs not have correct start and ends on line 31. So, I opened the g code in a viewer, and sure enough, the arc on line 31 is incorrect.

Did I mess something up, or is this a gremlin? And yes, the part is what it looks like! F360 and g code file attached.

Did I mess something up, or is this a gremlin? And yes, the part is what it looks like! F360 and g code file attached.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

23 Dec 2023 10:53 #288892

by rodw

Replied by rodw on topic Fusion 360 post processor file for Plamac

I prefer to create a DXF file from the sketch and lay out with Sheetcam (windows or Linux). For a simple test you can use sheetcam in demo mode.

From your model, find the sketch in the tree and right click to download a DXF. If its a folded part, flatten it and then create a new sketch on it. Don't add anything to it and you can create a DXF

From your model, find the sketch in the tree and right click to download a DXF. If its a folded part, flatten it and then create a new sketch on it. Don't add anything to it and you can create a DXF

Please Log in or Create an account to join the conversation.

- ashesman

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 4

24 Dec 2023 05:00 #288969

by ashesman

Replied by ashesman on topic Fusion 360 post processor file for Plamac

Thanks for your suggestion. I did just download sheetcam and have a play. The price is not too offensive. Not the nicest of user interfaces, but didn't take long to figure out.

I cant see anything it does that F360 doesn't do. Maybe you can shed some light on this?

F360 does parametric nesting, so you can alter your part and it will automatically lay out the nesting again (note nesting is a paid F360 feature). There is also no mucking around with exporting/importing DXFs (assuming your part is drawn in F360). Your CAM can stay with a part, or an assembly where you automatically nest all the parts of an assembly. F360 has all the same options for inside/outside offset compensation (actually much more control over the cut path). Has a tool library etc.

I cant see anything it does that F360 doesn't do. Maybe you can shed some light on this?

F360 does parametric nesting, so you can alter your part and it will automatically lay out the nesting again (note nesting is a paid F360 feature). There is also no mucking around with exporting/importing DXFs (assuming your part is drawn in F360). Your CAM can stay with a part, or an assembly where you automatically nest all the parts of an assembly. F360 has all the same options for inside/outside offset compensation (actually much more control over the cut path). Has a tool library etc.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

24 Dec 2023 10:06 #288981

by rodw

Replied by rodw on topic Fusion 360 post processor file for Plamac

If it works, it works. Few people have licensed the F360 nesting module so Sheetcam gives them well priced nesting that has good integration to qtplasmc. And it runs on Linux as well as Windows. Plus you can import tools from sheetcam into plasmac.The SC post might have tighter integration with plasmac as Les Newell the owner of Sheetcam has been known to do a bit of development with linuxcnc too.

Please Log in or Create an account to join the conversation.

- ashesman

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 4

26 Dec 2023 07:37 #289067

by ashesman

Replied by ashesman on topic Fusion 360 post processor file for Plamac

Yup, some good points there. Probably F360 for those on a budget, and when you are making one off parts that are designed in 360 and/or part of a bigger assembly.

Sheetcam for anything else... It is definitely more cost effective.

I would still be keen to get the F360 post processor working properly...

Sheetcam for anything else... It is definitely more cost effective.

I would still be keen to get the F360 post processor working properly...

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.165 seconds