PlasmaC Fiber laser 1Kw head height control + auto focuas

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

03 Apr 2020 12:25 - 03 Apr 2020 12:28 #162572

by taloot

Replied by taloot on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

i dont think its good idea,,,

it relies on factors

1, distance between head and work-peace (piercing and cutting have different focuas

2 material thickness

3 speed of cut ( fine tuning)

its better to be configured same as material,, in plasmac

it relies on factors

1, distance between head and work-peace (piercing and cutting have different focuas

2 material thickness

3 speed of cut ( fine tuning)

its better to be configured same as material,, in plasmac

Last edit: 03 Apr 2020 12:28 by taloot.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

03 Apr 2020 22:54 #162614

by phillc54

Replied by phillc54 on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

PlasmaC use external offsets to control Z motion.

linuxcnc.org/docs/devel/html/motion/external-offsets.html

linuxcnc.org/docs/devel/html/motion/external-offsets.html

The following user(s) said Thank You: taloot

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

03 Apr 2020 23:22 #162617

by rodw

Replied by rodw on topic PlasmaC Fiber laser 1Kw head height control + auto focuas

Perhaps the focus motor is an axis that is controlled by a hal component which in turn applies an external offset to that axis so no gcode is required. So again similar to Plasmac.

The following user(s) said Thank You: taloot

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

04 Apr 2020 12:23 #162668

by taloot

Replied by taloot on topic PlasmaC Fiber laser 1Kw head height control + auto focuas

yes and i want to link it to plasmac material controlPerhaps the focus motor is an axis that is controlled by a hal component which in turn applies an external offset to that axis so no gcode is required. So again similar to Plasmac.

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

04 Apr 2020 12:27 - 04 Apr 2020 12:28 #162670

by taloot

i want to use plasmac material control to adjust the height of head, focas. and piering highet so operator can choose the material and all setting adjusted based on that,, also gas pressure

Replied by taloot on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

PlasmaC use external offsets to control Z motion.

linuxcnc.org/docs/devel/html/motion/external-offsets.html

i want to use plasmac material control to adjust the height of head, focas. and piering highet so operator can choose the material and all setting adjusted based on that,, also gas pressure

Last edit: 04 Apr 2020 12:28 by taloot.

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

04 Apr 2020 16:45 #162687

by taloot

Replied by taloot on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

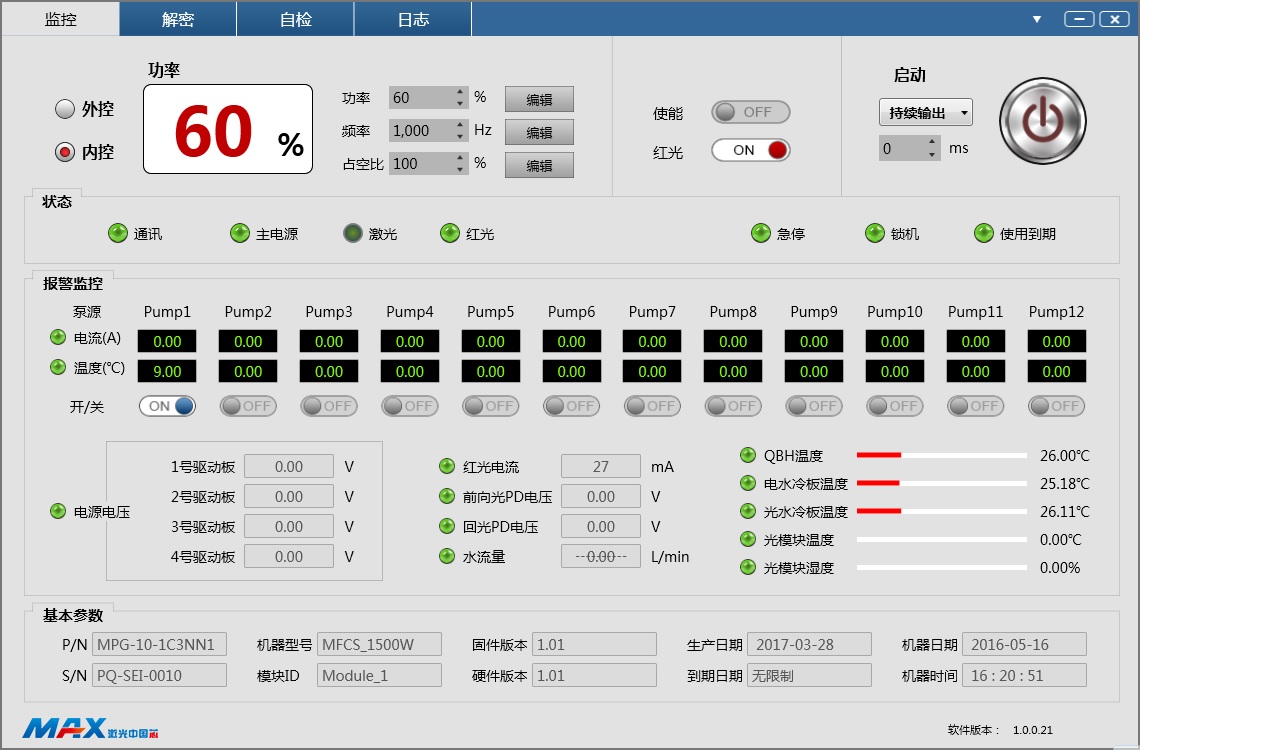

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

04 Apr 2020 23:14 - 04 Apr 2020 23:15 #162718

by phillc54

github.com/LinuxCNC/linuxcnc/blob/master...ne/plasmac/pmx485.py

Replied by phillc54 on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

all the Plasmac RS485 stuff is in here, it is Modbus ASCII @ 19200also whats the best way to change the rs485 protocol to use same as laser source and i have the protocol for this from laser manufacturer

github.com/LinuxCNC/linuxcnc/blob/master...ne/plasmac/pmx485.py

Last edit: 04 Apr 2020 23:15 by phillc54.

The following user(s) said Thank You: taloot

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

09 Apr 2020 00:01 #163257

by taloot

Replied by taloot on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

okey i have some updates,

i used the capacitance to 0-10 converter. and its connected to THCAD10 and from THCad ---->7i96

probe is fixed

i configure the focus as an axis, and i will control it with external offset for piercing i have specific focus value and another one for focus

also i have the protocol for the laser on RS232,,, i can choose the frequency and the power of the laser ( change them according to my need) cut or engrave

1.i want to link the rs232 to control the laser power.. what hal pin represent this in plasmac and how can i do it to control the power

2.i want to make vitrual insturment dashboard for the laser source,, whats the best method to do this ( i m using buster debian )

i used the capacitance to 0-10 converter. and its connected to THCAD10 and from THCad ---->7i96

probe is fixed

i configure the focus as an axis, and i will control it with external offset for piercing i have specific focus value and another one for focus

also i have the protocol for the laser on RS232,,, i can choose the frequency and the power of the laser ( change them according to my need) cut or engrave

1.i want to link the rs232 to control the laser power.. what hal pin represent this in plasmac and how can i do it to control the power

2.i want to make vitrual insturment dashboard for the laser source,, whats the best method to do this ( i m using buster debian )

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

09 Apr 2020 01:08 #163269

by phillc54

Replied by phillc54 on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

PlasmaC doesn't use anything like that, the torch is either on or off.

If you want to set the power from gcode, you may be able to use one of the spindle speed pins from motion or if you need to set the laser power according to velocity you could run the X and Y joint velocities into a hypot component.

linuxcnc.org/docs/2.8/html/man/man9/motion.9.html

linuxcnc.org/docs/2.8/html/man/man9/hypot.9.html

If you want to set the power from gcode, you may be able to use one of the spindle speed pins from motion or if you need to set the laser power according to velocity you could run the X and Y joint velocities into a hypot component.

linuxcnc.org/docs/2.8/html/man/man9/motion.9.html

linuxcnc.org/docs/2.8/html/man/man9/hypot.9.html

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

09 Apr 2020 01:56 #163278

by taloot

on plasmac rs485 can set the amp right?

Replied by taloot on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

Communications can be established with a Hypertherm Powermax plasma cutter that has a RS485 port. This then enables the setting of Cut Mode, Cutting Amperage and Gas Pressure automatically from the Cut Parameters of the material file.PlasmaC doesn't use anything like that, the torch is either on or off.

If you want to set the power from gcode, you may be able to use one of the spindle speed pins from motion or if you need to set the laser power according to velocity you could run the X and Y joint velocities into a hypot component.

linuxcnc.org/docs/2.8/html/man/man9/motion.9.html

linuxcnc.org/docs/2.8/html/man/man9/hypot.9.html

on plasmac rs485 can set the amp right?

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 1.889 seconds