Some thoughts and some findings using PlasmaC

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7248

14 Oct 2020 22:59 #186138

by tommylight

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

It is enough to repeatedly notice just by looking at it.

I have a stinking suspicion that is causing misfires very often.

PlasmaC is set in mode 0 for now, i do have a reed switch installed and ready to be wired to the input, but this same thing happened with mode 1 and since that was not my plasma source i could not experiment with it, not this one is also not mine but it is and will be in my shop for some more days. This one will delay the first torch on for about 1 sec then have no delay at all on all subsequent fires, it just fires instantly and never fails. It is a 120A Cebora, pretty old HF/HV pilot arc one with a THCAD300 installed on the outside.

I have a stinking suspicion that is causing misfires very often.

PlasmaC is set in mode 0 for now, i do have a reed switch installed and ready to be wired to the input, but this same thing happened with mode 1 and since that was not my plasma source i could not experiment with it, not this one is also not mine but it is and will be in my shop for some more days. This one will delay the first torch on for about 1 sec then have no delay at all on all subsequent fires, it just fires instantly and never fails. It is a 120A Cebora, pretty old HF/HV pilot arc one with a THCAD300 installed on the outside.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

15 Oct 2020 06:06 #186152

by phillc54

Replied by phillc54 on topic Some thoughts and some findings using PlasmaC

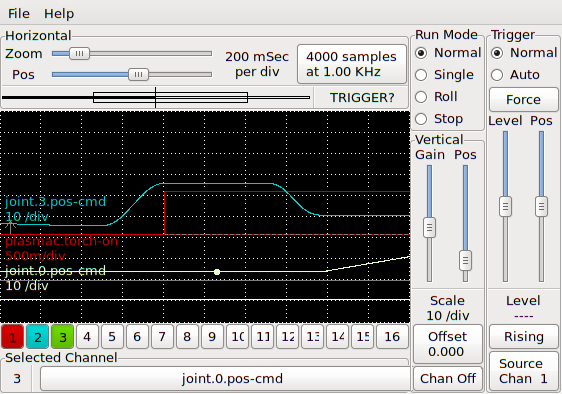

OK, I got that sorted as shown below but while doing it I noticed that motion starting after the pierce delay may be wrong.

At the moment it holds X/Y motion until cut height is reached which seems to really make a long pierce delay:

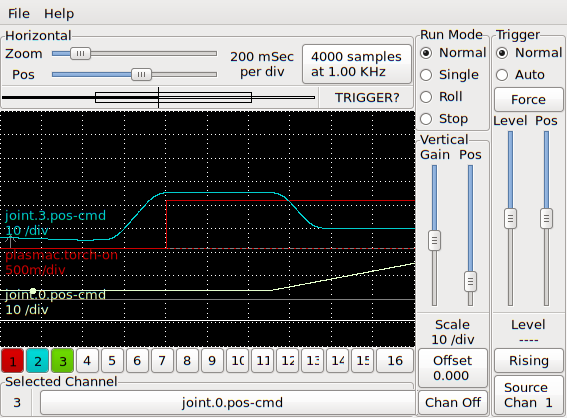

Would it be better to allow motion as soon as the pierce delay has finished, it means that Z will move down to cut height when X/Y motion has begun:

At the moment it holds X/Y motion until cut height is reached which seems to really make a long pierce delay:

Would it be better to allow motion as soon as the pierce delay has finished, it means that Z will move down to cut height when X/Y motion has begun:

Attachments:

The following user(s) said Thank You: tommylight, snowgoer540

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

15 Oct 2020 08:44 #186167

by snowgoer540

I have definitely noticed this before...

My vote is the latter. I think as soon as the pierce delay is expired it should start XY motion WHILE moving to cut height (which will all be part of the lead in anyways). While it doesn’t specifically mention XY motion, that was my interpretation of the Hypertherm THC manual’s chart showing what movements happen when for Z axis.

Also, for thicker materials, I always find myself adjusting the pierce delay to make it shorter, otherwise I get some unstable/unpredictable behavior at the beginning of the cut (because the pierce delay seems to be too long). In all cases, the material was already pierced when it flamed out.

I’m also willing to do some testing on this if you made a test branch. If that is something you’re interested in, it would be convenient to have a check box to toggle between the modes I would be testing (move to cut height then XY vs move to cut height at the same time as XY).

-Greg

Replied by snowgoer540 on topic Some thoughts and some findings using PlasmaC

OK, I got that sorted as shown below but while doing it I noticed that motion starting after the pierce delay may be wrong.

At the moment it holds X/Y motion until cut height is reached which seems to really make a long pierce delay:

Would it be better to allow motion as soon as the pierce delay has finished, it means that Z will move down to cut height when X/Y motion has begun:

I have definitely noticed this before...

My vote is the latter. I think as soon as the pierce delay is expired it should start XY motion WHILE moving to cut height (which will all be part of the lead in anyways). While it doesn’t specifically mention XY motion, that was my interpretation of the Hypertherm THC manual’s chart showing what movements happen when for Z axis.

Also, for thicker materials, I always find myself adjusting the pierce delay to make it shorter, otherwise I get some unstable/unpredictable behavior at the beginning of the cut (because the pierce delay seems to be too long). In all cases, the material was already pierced when it flamed out.

I’m also willing to do some testing on this if you made a test branch. If that is something you’re interested in, it would be convenient to have a check box to toggle between the modes I would be testing (move to cut height then XY vs move to cut height at the same time as XY).

-Greg

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

15 Oct 2020 10:13 - 15 Oct 2020 11:40 #186174

by snowgoer540

Replied by snowgoer540 on topic Some thoughts and some findings using PlasmaC

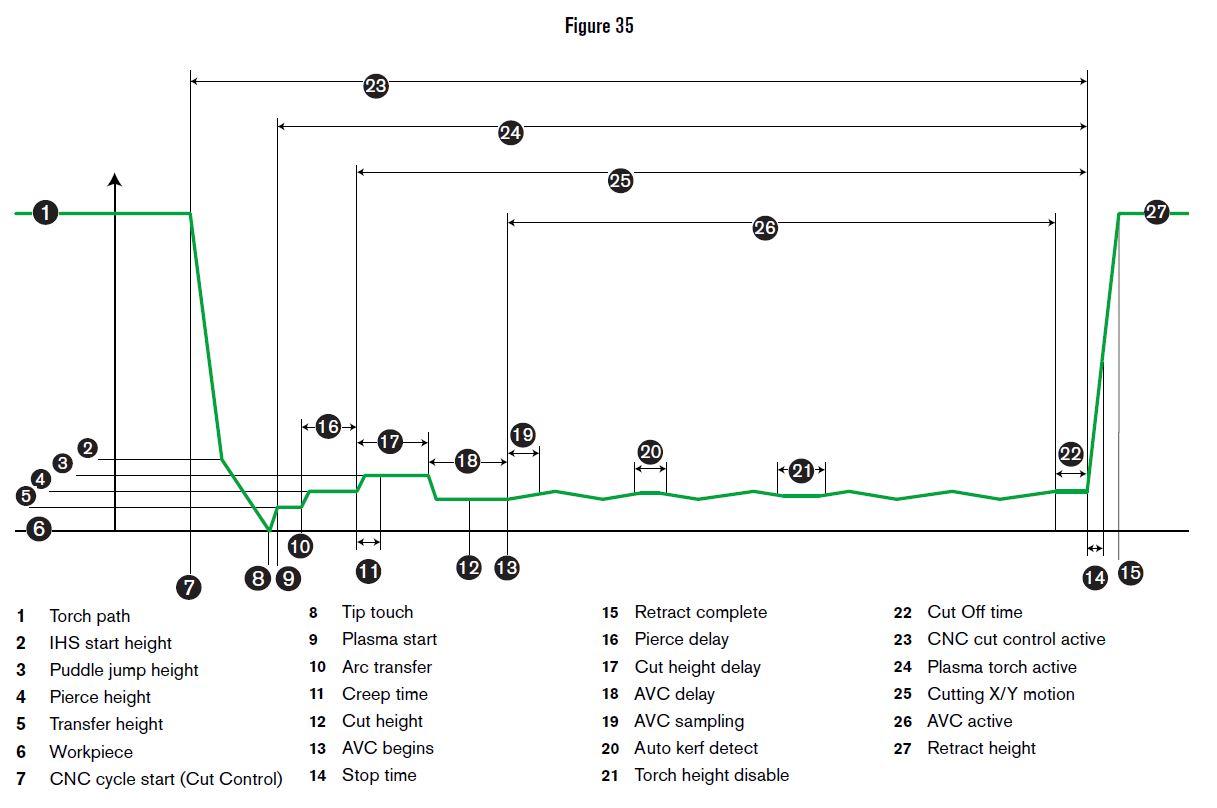

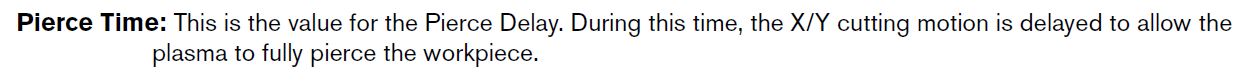

Actually, I take that back. The Hypertherm manual does specifically show when X/Y motion begins. It is number 25 on the chart below. Also, they use something called a "Transfer Height", which according to their definition is used to stretch the arc TO pierce height because on thick materials with a high pierce height, an arc transfer may not occur at all (Since I'm guessing this manual is meant for HD power sources that cut THICK material, "transfer height" probably isn't relevant for our setups, but it's interesting to note that it does exist).

Here's how I read the chart with starting with the torch touch (No. 8 on the chart):

a. Tip Touch (8)

b. Move to Transfer Height (5)

c. Plasma Start (9) and Plasma Torch becomes Active (24)

d. Arc Transfer (10) while moving to Pierce height (4)

e. Pierce Delay (16)

f. Cutting X/Y motion begins (25)

optional if puddle jump - g. Move to puddle Jump height (if set in our case) (3)

optional if puddle jump - h. Creep time (specifies the amount of time after piercing the workpiece that the torch travels at Creep Speed, the torch accelerates to cut speed after the creep time elapses) (11)

optional if puddle jump - i. Cut height delay (this is puddle jump delay in our terms) (17)

j. Torch moves to cut height (12) and AVC (THC for us) delay timer starts (18)

k. AVC (THC for us) starts sampling voltage (19) and starts controlling the torch (26)

To me, that pretty definitively shows that X/Y should begin after the pierce delay expires WHILE moving to cut height.

Here's some of the terms from above out of the manual

Here's how I read the chart with starting with the torch touch (No. 8 on the chart):

a. Tip Touch (8)

b. Move to Transfer Height (5)

c. Plasma Start (9) and Plasma Torch becomes Active (24)

d. Arc Transfer (10) while moving to Pierce height (4)

e. Pierce Delay (16)

f. Cutting X/Y motion begins (25)

optional if puddle jump - g. Move to puddle Jump height (if set in our case) (3)

optional if puddle jump - h. Creep time (specifies the amount of time after piercing the workpiece that the torch travels at Creep Speed, the torch accelerates to cut speed after the creep time elapses) (11)

optional if puddle jump - i. Cut height delay (this is puddle jump delay in our terms) (17)

j. Torch moves to cut height (12) and AVC (THC for us) delay timer starts (18)

k. AVC (THC for us) starts sampling voltage (19) and starts controlling the torch (26)

To me, that pretty definitively shows that X/Y should begin after the pierce delay expires WHILE moving to cut height.

Here's some of the terms from above out of the manual

Attachments:

Last edit: 15 Oct 2020 11:40 by snowgoer540. Reason: Remembered the alphabet, apparently.

The following user(s) said Thank You: phillc54, rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11666

- Thank you received: 3930

15 Oct 2020 10:41 #186179

by rodw

Replied by rodw on topic Some thoughts and some findings using PlasmaC

Geez, Test Pilot. That was deep dive from 30,000 ft!

I really think you need to upgrade your fighter jet so you can play with some 3/4" (oops I mean 19mm!)

I did a few cuts on 16mm but only on some bar stock, not a full sheet. I'll leave that to real fabricators like Stefan!

I will say a lot of the data is based on cutting similar thickness material. It is a bit different!

I really think you need to upgrade your fighter jet so you can play with some 3/4" (oops I mean 19mm!)

I did a few cuts on 16mm but only on some bar stock, not a full sheet. I'll leave that to real fabricators like Stefan!

I will say a lot of the data is based on cutting similar thickness material. It is a bit different!

The following user(s) said Thank You: snowgoer540

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

15 Oct 2020 11:39 #186185

by snowgoer540

I definitely agree, if you'd like to help by providing financial backing for my move from a PowerMax 65, to a Powermax 105, for testing purposes and the betterment of the group, of course, that might speed things along .. Otherwise, the thought of loading a sheet that thick means I will also likely need a forklift lol.

.. Otherwise, the thought of loading a sheet that thick means I will also likely need a forklift lol.

I see that the 105 cut chart lists a pierce height of .24" for the 3/4" material. As a nifty test, I wonder if I could get a cutting arc from .24", and where the threshold of "too high to get a cutting arc" begins. Of course this would just be a data point for my particular hypertherm, but it would be neat to know anyways. I suspect I would be able to get an arc from over .5"

Replied by snowgoer540 on topic Some thoughts and some findings using PlasmaC

Geez, Test Pilot. That was deep dive from 30,000 ft!

I really think you need to upgrade your fighter jet so you can play with some 3/4" (oops I mean 19mm!)

I did a few cuts on 16mm but only on some bar stock, not a full sheet. I'll leave that to real fabricators like Stefan!

I will say a lot of the data is based on cutting similar thickness material. It is a bit different!

I definitely agree, if you'd like to help by providing financial backing for my move from a PowerMax 65, to a Powermax 105, for testing purposes and the betterment of the group, of course, that might speed things along

I see that the 105 cut chart lists a pierce height of .24" for the 3/4" material. As a nifty test, I wonder if I could get a cutting arc from .24", and where the threshold of "too high to get a cutting arc" begins. Of course this would just be a data point for my particular hypertherm, but it would be neat to know anyways. I suspect I would be able to get an arc from over .5"

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11666

- Thank you received: 3930

15 Oct 2020 12:21 #186189

by rodw

Sorry I priced one and it made my eyes water! I sold my Everlast and was plasmaless for a while. Then I moved out of home to a shop with 3 phase power so I was looking at buying a 65 amp one but then I found a brand new old stock Thermal Dynamics 120 amp machine for $5k which saved me about $3k. I just had a look 3/4" pierce height is 0.25" and 1.6 sec pierce delay. The 16mm I tried only took 0.7 sec pierce delay but the arc had burnt about half way through before the arcOK came on!

And I needed a forklift to load 1/4"!

Replied by rodw on topic Some thoughts and some findings using PlasmaC

I definitely agree, if you'd like to help by providing financial backing for my move from a PowerMax 65, to a Powermax 105, for testing purposes and the betterment of the group, of course, that might speed things along

.. Otherwise, the thought of loading a sheet that thick means I will also likely need a forklift lol.

I see that the 105 cut chart lists a pierce height of .24" for the 3/4" material. As a nifty test, I wonder if I could get a cutting arc from .24", and where the threshold of "too high to get a cutting arc" begins. Of course this would just be a data point for my particular hypertherm, but it would be neat to know anyways. I suspect I would be able to get an arc from over .5"

Sorry I priced one and it made my eyes water! I sold my Everlast and was plasmaless for a while. Then I moved out of home to a shop with 3 phase power so I was looking at buying a 65 amp one but then I found a brand new old stock Thermal Dynamics 120 amp machine for $5k which saved me about $3k. I just had a look 3/4" pierce height is 0.25" and 1.6 sec pierce delay. The 16mm I tried only took 0.7 sec pierce delay but the arc had burnt about half way through before the arcOK came on!

And I needed a forklift to load 1/4"!

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7248

15 Oct 2020 12:42 #186195

by tommylight

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

Not sure but this might help with thicker materials as whenever the move starts on fast accelerating machines the arc has trouble keeping up a clean cut for a split second there and since that almost always happens on a bend or a lead in the arc will tend to keep that slope while cutting. This way moving the torch downwards might help put more air pressure at that part of the cut.

Would it be better to allow motion as soon as the pierce delay has finished, it means that Z will move down to cut height when X/Y motion has begun:

The following user(s) said Thank You: phillc54, snowgoer540

Please Log in or Create an account to join the conversation.

- CBEAR

- Offline

- Senior Member

-

Less

More

- Posts: 64

- Thank you received: 46

16 Oct 2020 12:39 #186276

by CBEAR

Replied by CBEAR on topic Some thoughts and some findings using PlasmaC

You can cut 3/4" Just fine with your pm65. If I clean cut 7/8" With my old 40 amp miller inverter machine, you can definitely cut 3/4" with your 65 amp machine. It may not be recommended:-) but it will do it just fine.

Please Log in or Create an account to join the conversation.

- CBEAR

- Offline

- Senior Member

-

Less

More

- Posts: 64

- Thank you received: 46

16 Oct 2020 12:44 #186277

by CBEAR

Replied by CBEAR on topic Some thoughts and some findings using PlasmaC

Tommy is correct. I believe that it is for thicker material. So that it can apply more air pressure and blow through thicker material. Think of it like cutting with an oxyacetylene torch. For thicker material, you can also change your type of lead in to "wiggle" in sheetcam. It makes for some violent sparks, but is easier on consumables while piercing thicker materials. The majority of consumable wear occurs during piercing. You could cut all day long on a single pierce if your plasma cutter and air compressor were 100% duty cycle, but piercing, especially through thick material, eats up consumables rather quickly.

The following user(s) said Thank You: tommylight, Mud, snowgoer540

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 2.575 seconds