Some thoughts and some findings using PlasmaC

- Mud

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 25

16 Oct 2020 14:35 #186287

by Mud

Replied by Mud on topic Some thoughts and some findings using PlasmaC

Ah, hadn't spotted the wiggle option - interesting. I was struggling to pierce 10mm without a gob jumping up and melting the plastic nozzle outer...I'll give it a go

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

16 Oct 2020 15:50 - 16 Oct 2020 15:51 #186294

by snowgoer540

Can cut, and Want to cut are two totally different things

3/4" is heavy

3/4" is heavy

But you are correct, edge start for a PMX65 starts at 3/4 and goes to 7/8, and like you said, I imagine you could go past that without the cutter whimpering. I was jus trying to figure out what a realistic pierce height was to see if "transfer height" really affected any of us Air Plasma folk.

I didn't know about wiggle either. That reminds me of a spiral lead in in Fusion360 instead of a plunge cut to make it easier on the endmill/machine. But with way more sparks

Replied by snowgoer540 on topic Some thoughts and some findings using PlasmaC

You can cut 3/4" Just fine with your pm65. If I clean cut 7/8" With my old 40 amp miller inverter machine, you can definitely cut 3/4" with your 65 amp machine. It may not be recommended:-) but it will do it just fine.

Can cut, and Want to cut are two totally different things

But you are correct, edge start for a PMX65 starts at 3/4 and goes to 7/8, and like you said, I imagine you could go past that without the cutter whimpering. I was jus trying to figure out what a realistic pierce height was to see if "transfer height" really affected any of us Air Plasma folk.

I didn't know about wiggle either. That reminds me of a spiral lead in in Fusion360 instead of a plunge cut to make it easier on the endmill/machine. But with way more sparks

Last edit: 16 Oct 2020 15:51 by snowgoer540.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7248

19 Oct 2020 00:59 #186536

by tommylight

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

Did some more tests today with other settings as the new build is not on buildbot yet, so here are some more findings:

-Use Auto Volts works properly on all accounts, have to do some more testing with the "height per volt" setting to get proper height during cutting.

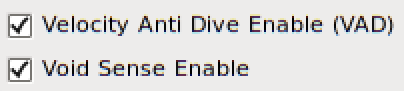

-Velocity anti dive works OK but it does come on occasionally on straight cuts, it should not. Also the naming will be confusing for users; "velocity anti dive enable" on the RUN tab, VAD on the config tab and "THC velocity lock" on the LED.

-Void sense enable on the RUN tab, void override on the config tab, THC void lock on LED, Works when set to 400% although it does come on occasionally and stays on to long, at 100% it is on most of the time during straight cuts. But in general it does work as i could see it come on when passing a void and off when the void was passed. Thinking that i need to do some more tests with lowpas for arc voltage at different values as mpst of the issues could be due to very fast changes in voltage that THCAD has no problem reading and LinuxCNC has no problem reacting to it.

Ah, the joy of having to fast .... everything !

-Use Auto Volts works properly on all accounts, have to do some more testing with the "height per volt" setting to get proper height during cutting.

-Velocity anti dive works OK but it does come on occasionally on straight cuts, it should not. Also the naming will be confusing for users; "velocity anti dive enable" on the RUN tab, VAD on the config tab and "THC velocity lock" on the LED.

-Void sense enable on the RUN tab, void override on the config tab, THC void lock on LED, Works when set to 400% although it does come on occasionally and stays on to long, at 100% it is on most of the time during straight cuts. But in general it does work as i could see it come on when passing a void and off when the void was passed. Thinking that i need to do some more tests with lowpas for arc voltage at different values as mpst of the issues could be due to very fast changes in voltage that THCAD has no problem reading and LinuxCNC has no problem reacting to it.

Ah, the joy of having to fast .... everything !

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

19 Oct 2020 02:39 #186542

by phillc54

Replied by phillc54 on topic Some thoughts and some findings using PlasmaC

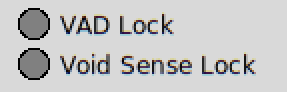

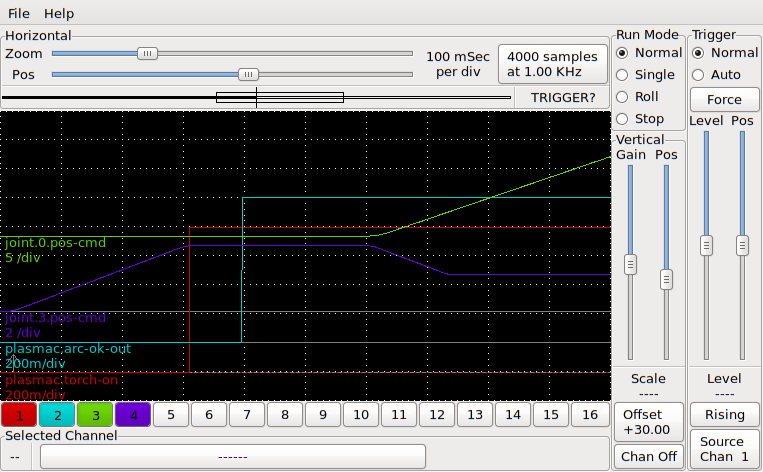

How about this Tom?

Run Panel:

Config Panel:

Monitor Panel:

Regarding VAD, are you using F#<_hal[plasmac.cut-feed-rate]> as the feed rate or Fnnnn.

For void sensing I have had good results with 100%. I guess there may be some differences between machines. There is an as yet undocumented hal parameter that you could try. It is named (for historical reasons) plasmac.kerf-errors-max. It is the number of consecutive times the threshold is exceeded for the lock to be valid. The default value is 2. It may be better for you to increase that to 3 or maybe even more.

Run Panel:

Config Panel:

Monitor Panel:

Regarding VAD, are you using F#<_hal[plasmac.cut-feed-rate]> as the feed rate or Fnnnn.

For void sensing I have had good results with 100%. I guess there may be some differences between machines. There is an as yet undocumented hal parameter that you could try. It is named (for historical reasons) plasmac.kerf-errors-max. It is the number of consecutive times the threshold is exceeded for the lock to be valid. The default value is 2. It may be better for you to increase that to 3 or maybe even more.

Attachments:

The following user(s) said Thank You: tommylight, pinder

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7248

19 Oct 2020 12:12 #186571

by tommylight

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

Much better and more uniform, thank you.

And yes i am using #F as i am doing all the testing from the wizard.

I'll give that a try whenever i get the chance and report back.

Thank you.

And yes i am using #F as i am doing all the testing from the wizard.

I'll give that a try whenever i get the chance and report back.

Thank you.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7248

20 Oct 2020 11:53 #186672

by tommylight

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

Did some more testes yesterday regarding the torch on and arcok signals and found out that the best value for arcok debounce is 1 in my case.

Luckily i could not break anything else !

Luckily i could not break anything else !

The following user(s) said Thank You: phillc54, snowgoer540

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

21 Oct 2020 03:13 - 21 Oct 2020 03:15 #186787

by phillc54

Replied by phillc54 on topic Some thoughts and some findings using PlasmaC

Attachments:

Last edit: 21 Oct 2020 03:15 by phillc54.

The following user(s) said Thank You: tommylight, pinder

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7248

21 Oct 2020 12:32 #186809

by tommylight

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

Looks much better, when can i give it a run?

Thank you.

Thank you.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

21 Oct 2020 15:53 #186816

by snowgoer540

That's a question only you can answer; she's live now! Seems to work well from what I saw. Seems like it solved a lot of the joint following issues we were seeing as well.

Seems to work well from what I saw. Seems like it solved a lot of the joint following issues we were seeing as well.

I didn't get to do a ton of testing on it, but preliminary results were very encouraging.

Replied by snowgoer540 on topic Some thoughts and some findings using PlasmaC

Looks much better, when can i give it a run?

Thank you.

That's a question only you can answer; she's live now!

I didn't get to do a ton of testing on it, but preliminary results were very encouraging.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7248

21 Oct 2020 20:19 #186837

by tommylight

Replied by tommylight on topic Some thoughts and some findings using PlasmaC

I did play a bit with it today, i is definitely much, much better, so more testing is on order for tomorrow.

I had everything at default regarding debouncing and some other stuff and old consumables and on most fails it was the plasma source that failed to start the arc, but out of 100 starts it failed about 15 times while before it was 2 or 3 times per pierce after the first one.

Warning:

Do not take any of this as a reference to anything, i am using a very old Cebora plasma source with a 12M long torch cable, plasma is in the workshop while the machine is outside sitting on stilts (temporarily = yeah riteee ), very long cables going from the machine to the plasma source, computer and monitor are also outside in the cold, etc, etc, .

), very long cables going from the machine to the plasma source, computer and monitor are also outside in the cold, etc, etc, .

The reason for all this is to make it work with worst case conditions and iron out small wrinkles so when using proper stuff it never fails.

I had everything at default regarding debouncing and some other stuff and old consumables and on most fails it was the plasma source that failed to start the arc, but out of 100 starts it failed about 15 times while before it was 2 or 3 times per pierce after the first one.

Warning:

Do not take any of this as a reference to anything, i am using a very old Cebora plasma source with a 12M long torch cable, plasma is in the workshop while the machine is outside sitting on stilts (temporarily = yeah riteee

The reason for all this is to make it work with worst case conditions and iron out small wrinkles so when using proper stuff it never fails.

The following user(s) said Thank You: phillc54, snowgoer540

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 3.196 seconds