Postprozessor Fusion 360 PlasmaC

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

02 Jun 2021 09:10 #210978

by tommylight

Replied by tommylight on topic Postprozessor Fusion 360 PlasmaC

I would fist check for EMI related issues, it is the main cause of arc lost.

As for derrived arcok, i am still using it on my machines, so far there are 4 in daily use, all work properly with default values in QTPlasmaC.

As for derrived arcok, i am still using it on my machines, so far there are 4 in daily use, all work properly with default values in QTPlasmaC.

Please Log in or Create an account to join the conversation.

- MaikTheBike

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 1

06 Jun 2021 06:26 #211277

by MaikTheBike

Replied by MaikTheBike on topic Postprozessor Fusion 360 PlasmaC

Thanks Phil,

PlasmaC works now and I can cut with it. I added a delay for the loss of arc as you described. Very nice.

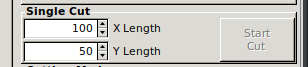

I cut some pieces and also tried out the "cut xxx mm in x or y direction-button".

When I press this button, in most cases the z-axis goes down and starts the cut in x or y. But sometimes the Z-axis seems to go up when I use this function ? Maybe its looking for an end-switch (I don't have any at the moment) ? But why does it go up sometimes instead of going down and starting the cut ?

thanks for you help

PlasmaC works now and I can cut with it. I added a delay for the loss of arc as you described. Very nice.

I cut some pieces and also tried out the "cut xxx mm in x or y direction-button".

When I press this button, in most cases the z-axis goes down and starts the cut in x or y. But sometimes the Z-axis seems to go up when I use this function ? Maybe its looking for an end-switch (I don't have any at the moment) ? But why does it go up sometimes instead of going down and starting the cut ?

thanks for you help

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

06 Jun 2021 08:12 #211280

by phillc54

then that is odd behavoiur, it should attempt a probe first.

If the Z axis height when you press the Start Cut button was lower than the Probe Height setting in the Run Panel then it would need to move up to get to probe height.

Replied by phillc54 on topic Postprozessor Fusion 360 PlasmaC

If you mean this:I cut some pieces and also tried out the "cut xxx mm in x or y direction-button".

When I press this button, in most cases the z-axis goes down and starts the cut in x or y. But sometimes the Z-axis seems to go up when I use this function ? Maybe its looking for an end-switch (I don't have any at the moment) ? But why does it go up sometimes instead of going down and starting the cut ?

then that is odd behavoiur, it should attempt a probe first.

If the Z axis height when you press the Start Cut button was lower than the Probe Height setting in the Run Panel then it would need to move up to get to probe height.

Attachments:

Please Log in or Create an account to join the conversation.

- MaikTheBike

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 1

16 Jun 2021 18:59 #212210

by MaikTheBike

Replied by MaikTheBike on topic Postprozessor Fusion 360 PlasmaC

Thanks Phil.

Yes. Thats exactly the function I wrote about.

What I do is the following:

I start the PlasmaC-machine, Press F1, then F2, and home all axis.

Then I press the "start cut" button of the function. The machine starts to cut and everything is good.

After cutting the machine moves up and I have to press F1, because there are no limit/homing-switches on the machine. So if I don't press F1, the axis doesn't stop.

Then I press F1, F2 and Start Cut and the machine moves up instead of moving down. Maybe its because the machine doesn't have end-switches and I have to press F1 after the first cut ?

Thanks a lot,

Maik

Yes. Thats exactly the function I wrote about.

What I do is the following:

I start the PlasmaC-machine, Press F1, then F2, and home all axis.

Then I press the "start cut" button of the function. The machine starts to cut and everything is good.

After cutting the machine moves up and I have to press F1, because there are no limit/homing-switches on the machine. So if I don't press F1, the axis doesn't stop.

Then I press F1, F2 and Start Cut and the machine moves up instead of moving down. Maybe its because the machine doesn't have end-switches and I have to press F1 after the first cut ?

Thanks a lot,

Maik

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

16 Jun 2021 20:47 #212215

by tommylight

Replied by tommylight on topic Postprozessor Fusion 360 PlasmaC

-Z axis limits not set properly,

-probe speed to fast

-probe speed to fast

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

16 Jun 2021 23:59 #212238

by phillc54

Replied by phillc54 on topic Postprozessor Fusion 360 PlasmaC

Homing and limit switches are not mandatory. I don't use limit switches at all. But you must have the all the axes at the position it says HOME is at in the ini file when you home the machine and you must have the MIN_LIMI and MAX_LIMIT sttings correct.After cutting the machine moves up and I have to press F1, because there are no limit/homing-switches on the machine. So if I don't press F1, the axis doesn't stop.

Please Log in or Create an account to join the conversation.

- MaikTheBike

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 1

19 Jun 2021 16:07 #212417

by MaikTheBike

Replied by MaikTheBike on topic Postprozessor Fusion 360 PlasmaC

Thanks Phil.

I have to make sure that these settings are correct.

Until now I have only cut simple shapes like rectangles or circles and I wanted to cut a part from a DXF-file (a cat).

I imported the file into Fusion 360, generated the G-Code with the PlasmaC-PP and then there is an error in LinuxCNC:

"Radius to end of arc differs from radius to start" (in line 78)...

Maybe you have an Idea, what I'm doing wrong here ? The NGC-File and Fusion 360(F3d) are attached.

Thanks a lot,

Maik

I have to make sure that these settings are correct.

Until now I have only cut simple shapes like rectangles or circles and I wanted to cut a part from a DXF-file (a cat).

I imported the file into Fusion 360, generated the G-Code with the PlasmaC-PP and then there is an error in LinuxCNC:

"Radius to end of arc differs from radius to start" (in line 78)...

Maybe you have an Idea, what I'm doing wrong here ? The NGC-File and Fusion 360(F3d) are attached.

Thanks a lot,

Maik

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

20 Jun 2021 00:11 #212449

by phillc54

Replied by phillc54 on topic Postprozessor Fusion 360 PlasmaC

Maybe this thread will be of some help:

forum.linuxcnc.org/38-general-linuxcnc-q...o-start-error#116469

forum.linuxcnc.org/38-general-linuxcnc-q...o-start-error#116469

Please Log in or Create an account to join the conversation.

- MaikTheBike

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 1

27 Jun 2021 09:34 - 27 Jun 2021 09:36 #213012

by MaikTheBike

Replied by MaikTheBike on topic Postprozessor Fusion 360 PlasmaC

Thanks Phil.

I was able to solve the problem and PlasmaC seems to work now.

Today I tried spotting with the Fusion 360 Postprocessor as described in the PDF-manual of the PP

with Multiple-Tools set to 1 in the hal-file.

I created the G-Code and the machine did the centerpunch very well. Thats awesome.

But after punching the Z-Axis went up and down again to do a second punch at the same spot. Then it went up and down and did a third punch at the same spot. Then I stopped the program.

I looked at the GCode and linuxcnc stayed at line N105 X3.5, while the z-axis went up and down multiple times and did the punches.

Threshold was set to 120V and timeOn was 10ms. I don't know if these are good values for punching, but the "holes" punched looked nicely.

Thanks a lot,

Maik

I was able to solve the problem and PlasmaC seems to work now.

Today I tried spotting with the Fusion 360 Postprocessor as described in the PDF-manual of the PP

with Multiple-Tools set to 1 in the hal-file.

I created the G-Code and the machine did the centerpunch very well. Thats awesome.

But after punching the Z-Axis went up and down again to do a second punch at the same spot. Then it went up and down and did a third punch at the same spot. Then I stopped the program.

I looked at the GCode and linuxcnc stayed at line N105 X3.5, while the z-axis went up and down multiple times and did the punches.

Threshold was set to 120V and timeOn was 10ms. I don't know if these are good values for punching, but the "holes" punched looked nicely.

(PLASMAPUNCHTEST)

N10 G21

N15 G90 G40

N20 G17 G91.1

N25 G64 P0.254 Q0.254

N30 M52 P1.

N35 M65 P2.

N40 M65 P3.

N45 M68 E3 Q0.

(2D-PROFIL3 2)

(--------------------------------------------------------------------------------------------------)

(- THIS SECTION IS SET UP TO CENTER PUNCH THE SELECTED HOLES. -)

(- ANY OTHER TYPE OF OPERATIONS IN THIS SECTION WILL NOT WORK CORRECTLY -)

(--------------------------------------------------------------------------------------------------)

N50 F999999.

(PLASMA CUTTING)

(THROUGH CUTTING)

N55 M190 P1.

N60 M66 P3. L3 Q1.

N65 F#<_hal[plasmac.cut-feed-rate]>

N70 G0 X3.5 Y0.

N75 G0 X0.

(CENTER PUNCH THE HOLE ONLY)

N80 M3 $2 S1

N85 G91

N90 G1 X0.00001

N95 G90

N100 M5

N105 X3.5 <---- Program stayed here, while the Z-Axis did several punches

N110 F#<_hal[plasmac.cut-feed-rate]>

N115 G0 X0. Y0.

N120 G90

N125 G40

N130 M65 P2.

N135 M65 P3.

N140 M68 E3 Q0.

N145 M5

N150 M30Thanks a lot,

Maik

Last edit: 27 Jun 2021 09:36 by MaikTheBike.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

28 Jun 2021 01:02 - 28 Jun 2021 01:21 #213065

by phillc54

Replied by phillc54 on topic Postprozessor Fusion 360 PlasmaC

I ran the file here and it seems to run OK.

This line is not required:

Nor are these:

Although having said that, they shouldn't cause any problem apart from the error message caused by line N50.

EDIT: The issue is caused by this line:

It should be:

This line is not required:

N50 F999999.Nor are these:

N105 X3.5 <---- Program stayed here, while the Z-Axis did several punches

N110 F#<_hal[plasmac.cut-feed-rate]>Although having said that, they shouldn't cause any problem apart from the error message caused by line N50.

EDIT: The issue is caused by this line:

N100 M5It should be:

N100 M5$2

Last edit: 28 Jun 2021 01:21 by phillc54.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.095 seconds