setup qtplasmac

- fupeama

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 66

- Thank you received: 14

12 Jul 2021 13:40 - 12 Jul 2021 13:40 #214393

by fupeama

setup qtplasmac was created by fupeama

Hi, I'm building a plasma machine and I have some questions about how to set it up.

1. I would like to control the ARC override with an encoder so that. I don't want to use a mouse. When cutting, I look at the arc and the encoder would adjust the height as needed. Using a mouse is too complicated.

2.

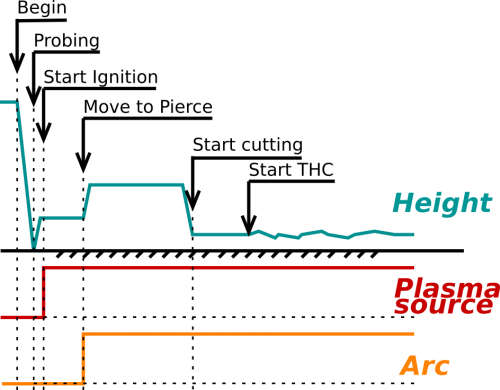

when cutting thick material, I need the torch to go up after the arc is ignited so that the blasting material does not spray on the nozzle. I am attaching a picture describing this function. This is how original software handled it.

is it possible to setup qtplasmac for this features?

Thanks Martin

1. I would like to control the ARC override with an encoder so that. I don't want to use a mouse. When cutting, I look at the arc and the encoder would adjust the height as needed. Using a mouse is too complicated.

2.

when cutting thick material, I need the torch to go up after the arc is ignited so that the blasting material does not spray on the nozzle. I am attaching a picture describing this function. This is how original software handled it.

is it possible to setup qtplasmac for this features?

Thanks Martin

Attachments:

Last edit: 12 Jul 2021 13:40 by fupeama.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

12 Jul 2021 15:00 #214400

by Clive S

Replied by Clive S on topic setup qtplasmac

qtplaasmac should do all that it using a Mesa THC10 card and generally the easiest route is to use a Mesa 7i96

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2541

- Thank you received: 867

12 Jul 2021 16:32 #214409

by snowgoer540

I would guess that it could be made to be possible, but it is not currently. The better question would be is it necessary... Have you used QtPlasmaC at all? You mentioned "this is how the original software handled it", I am wondering what you were using. At any rate, QtPlasmaC has "Auto Volts" which might negate the need for what you're describing.

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_thc

2:

That looks very much like a recreation of Hypertherm's diagram from their ARC GLIDE THC manual. QtPlasmaC follows that logic, with the exception of the "transfer arc" portion you describe. Again, it's probably possible, but I believe they do this so that they get a good transfer from pilot arc to cutting arc on High Definition plasma cutters. It seems to be less about consumables and more about the ability to establish a valid arc.

An excerpt from that manual "Transfer Height: When the arc transfers to the workpiece, it can be “stretched” to the pierce height. The transfer height is lower than the pierce height because initiating arc transfer at a high pierce height may result in the arc not transferring to the workpiece at all. Enter the Transfer Height as a percentage of the cut height or as an actual transfer height distance."

All that said, it doesn't mean there's not a use case out there for someone. From a splashback standpoint, I would think it matters how thick of material you are cutting. In the air plasma scene, I'm not sure it applies, most cut charts just go to "edge start" when that become a big deal.

I'm curious what the use case is, IE, how thick of stuff are you piercing, what power source are you using, etc.

Replied by snowgoer540 on topic setup qtplasmac

1:Hi, I'm building a plasma machine and I have some questions about how to set it up.

1. I would like to control the ARC override with an encoder so that. I don't want to use a mouse. When cutting, I look at the arc and the encoder would adjust the height as needed. Using a mouse is too complicated.

2.

when cutting thick material, I need the torch to go up after the arc is ignited so that the blasting material does not spray on the nozzle. I am attaching a picture describing this function. This is how original software handled it.

is it possible to setup qtplasmac for this features?

Thanks Martin

I would guess that it could be made to be possible, but it is not currently. The better question would be is it necessary... Have you used QtPlasmaC at all? You mentioned "this is how the original software handled it", I am wondering what you were using. At any rate, QtPlasmaC has "Auto Volts" which might negate the need for what you're describing.

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_thc

2:

That looks very much like a recreation of Hypertherm's diagram from their ARC GLIDE THC manual. QtPlasmaC follows that logic, with the exception of the "transfer arc" portion you describe. Again, it's probably possible, but I believe they do this so that they get a good transfer from pilot arc to cutting arc on High Definition plasma cutters. It seems to be less about consumables and more about the ability to establish a valid arc.

An excerpt from that manual "Transfer Height: When the arc transfers to the workpiece, it can be “stretched” to the pierce height. The transfer height is lower than the pierce height because initiating arc transfer at a high pierce height may result in the arc not transferring to the workpiece at all. Enter the Transfer Height as a percentage of the cut height or as an actual transfer height distance."

All that said, it doesn't mean there's not a use case out there for someone. From a splashback standpoint, I would think it matters how thick of material you are cutting. In the air plasma scene, I'm not sure it applies, most cut charts just go to "edge start" when that become a big deal.

I'm curious what the use case is, IE, how thick of stuff are you piercing, what power source are you using, etc.

Please Log in or Create an account to join the conversation.

- fupeama

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 66

- Thank you received: 14

13 Jul 2021 07:59 #214506

by fupeama

Replied by fupeama on topic setup qtplasmac

Hi,I'll try to describe it a little more.

I have no problem to configure mesa card. Current machine is build on mesa 7i76e 7i73 and THC10. All is ok, plasma is running. This machine is not mine but my friend's. I'm the one setting it up. The previous machine ran on very old software (PALCAD) similar to mycnc.

Here is picture that I used in previous post. I'm trying to set up the machine the way a friend is used to using it.

The question was asked how thick the material was.... max 20mm.On the previous machine, it was possible to switch to oxy fuel cutting, which is better for thicker material. I will probably solve this possibility later with a different configuration.

Plasma cutter is powermax 1650. It would be nice to have external inputs for example for THC on / off, reset ARC override and similar as it is now for start, stop program, pulse, probe, etc. And also the already mentioned arc override on the encoder.

excuse my simple englishMartin

I have no problem to configure mesa card. Current machine is build on mesa 7i76e 7i73 and THC10. All is ok, plasma is running. This machine is not mine but my friend's. I'm the one setting it up. The previous machine ran on very old software (PALCAD) similar to mycnc.

Here is picture that I used in previous post. I'm trying to set up the machine the way a friend is used to using it.

The question was asked how thick the material was.... max 20mm.On the previous machine, it was possible to switch to oxy fuel cutting, which is better for thicker material. I will probably solve this possibility later with a different configuration.

Plasma cutter is powermax 1650. It would be nice to have external inputs for example for THC on / off, reset ARC override and similar as it is now for start, stop program, pulse, probe, etc. And also the already mentioned arc override on the encoder.

excuse my simple englishMartin

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

13 Jul 2021 09:57 #214520

by rodw

Replied by rodw on topic setup qtplasmac

Plasmac has a puddle jump height which I thought was designed to achieve the increase in height from transfer to pierce height you've described but I've never needed to use it.

Most of the rest of your features are supported in the GUI which is touch screen friendly so there is no need for a mouse.

I agree the sliders of qtplasmac are crying out for encoder control. I thought they were recently supported but I can't see the pins in the instructions.

I would suggest you use it for a while before wanting to reinvent the wheel. There should be little need to customise it as the controls are there. Also learn to enjoy the auto volts sampling. I've never used anything else!

Most of the rest of your features are supported in the GUI which is touch screen friendly so there is no need for a mouse.

I agree the sliders of qtplasmac are crying out for encoder control. I thought they were recently supported but I can't see the pins in the instructions.

I would suggest you use it for a while before wanting to reinvent the wheel. There should be little need to customise it as the controls are there. Also learn to enjoy the auto volts sampling. I've never used anything else!

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

13 Jul 2021 10:12 #214529

by phillc54

Replied by phillc54 on topic setup qtplasmac

Puddle Jump is after piercing and before cut height.

You can control the sliders with the relevant halui pins.

You can control the sliders with the relevant halui pins.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7286

13 Jul 2021 10:33 #214533

by tommylight

Replied by tommylight on topic setup qtplasmac

What OP is asking is a Hypertherm HD feature for cutting thick material, so probe, go to lets call it "transfer" height usually 2 to 3mm, start the torch, as soon as it gets arcok it moves up another mm or two to awoid splashback to the nozzle, then slowly moves down during the pierce delay time to reach the cut height, then moves on to normal cutting.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

13 Jul 2021 10:36 - 13 Jul 2021 10:41 #214534

by phillc54

Replied by phillc54 on topic setup qtplasmac

I seem to recall quite some time back I asked whether it would be worthwhile adding this but from memory the consensus was that it wasn't really required.

Edit: found it forum.linuxcnc.org/plasma-laser/35449-an...nent?start=70#120725

Edit: found it forum.linuxcnc.org/plasma-laser/35449-an...nent?start=70#120725

Last edit: 13 Jul 2021 10:41 by phillc54.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7286

13 Jul 2021 11:29 - 13 Jul 2021 11:30 #214546

by tommylight

Replied by tommylight on topic setup qtplasmac

Yup, me too, but cutting 20mm plates with plasma is the "industrial" domain requiring 5 and 6 figure price tags.

Had several instances of trying to cut that with say 120A used and cheap plasma source, it can be done, but the results are usually disapointing, and nozzles run out rather quickly.

On the other hand, adding an Oxy Acetylene torch to the plasma machine does that easily and with style!

Depending on the torch, up to 160mm thickness can be cut with good results.

Edit:

Here i can find Oxy torches that can do 100mm for 190 Euro new, gas tanks are a bit more pricy

Had several instances of trying to cut that with say 120A used and cheap plasma source, it can be done, but the results are usually disapointing, and nozzles run out rather quickly.

On the other hand, adding an Oxy Acetylene torch to the plasma machine does that easily and with style!

Depending on the torch, up to 160mm thickness can be cut with good results.

Edit:

Here i can find Oxy torches that can do 100mm for 190 Euro new, gas tanks are a bit more pricy

Last edit: 13 Jul 2021 11:30 by tommylight. Reason: more info

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2541

- Thank you received: 867

13 Jul 2021 11:39 #214551

by snowgoer540

Replied by snowgoer540 on topic setup qtplasmac

I'd echo the sentiment of using QtPlasmaC for a bit, and see what you actually end up needing. Likely much of the functionality already exists; there's been a lot of input from a wide range of users, ranging from hobbyists to industrial businesses over the last few years.

That said, it is usually worth at least considering/discussing new ideas.

That said, it is usually worth at least considering/discussing new ideas.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.126 seconds