- User Interfaces

- Plasmac

- qtplasmac 2.10 arc ok, thcad thc, and Thcad Ohmic troubleshooting help needed.

qtplasmac 2.10 arc ok, thcad thc, and Thcad Ohmic troubleshooting help needed.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

z axis, if failed to home (broken stepper wire) would still cause the x and y axis to move even after it failed!!!!!! had this happen twice over the last year with the thin nema 17 wires breaking at the connectors after all those pierces.

This looks like a LinuxCNC bug, I see the same behaviour in AXIS. I get the below error message but X and Y do go through their homing sequence.

Attachments:

Please Log in or Create an account to join the conversation.

- jimmyrig

- Offline

- Premium Member

-

- Posts: 130

- Thank you received: 40

github.com/LinuxCNC/linuxcnc/issues/2983

this is in the homing.c file

here is the code throwing the error, think it calls home abort for the joint

/* check for reached end of move */

if (! (&joints[jno])->free_tp.active) {

/* reached end of move without hitting switch */

(&joints[jno])->free_tp.enable = 0;

rtapi_print_msg(RTAPI_MSG_ERR,_("j%d end of move in home state %d"),jno, H[jno].home_state);

H[jno].home_state = HOME_ABORT;

return 1; // abort reqd

}

However the home abort case only does the current joint not all of them.

case HOME_ABORT:

H[joint_num].homing = 0;

H[joint_num].homed = 0;

H[joint_num].joint_in_sequence = 0;

joint->free_tp.enable = 0;

H[joint_num].home_state = HOME_IDLE;

H[joint_num].index_enable = 0;

immediate_state = 1;

break;

simple loop might fix the issue??? hope im understanding this correctly. e.g.

case HOME_ABORT:

for (int i = 0; i < all_joints; i++) {

H.homing = 0;

H.homed = 0;

H.joint_in_sequence = 0;

H.home_state = HOME_IDLE;

H.index_enable = 0;

joints.free_tp.enable = 0;

}

immediate_state = 1;

break;

Please Log in or Create an account to join the conversation.

- jimmyrig

- Offline

- Premium Member

-

- Posts: 130

- Thank you received: 40

running the linuxcnc 2.9.2 downloadable iso for debian 12

pulled master from git

Made the changes,

compiled the code with some prints using

cd src

./configure

make

sudo make setuid

with this code

case HOME_ABORT:

rtapi_print_msg(RTAPI_MSG_ERR, "Entering HOME_ABORT state\n");

for (int i = 0; i < all_joints; i++) {

rtapi_print_msg(RTAPI_MSG_ERR, "Aborting joint %d\n", i);

H[joint_num].homing = 0;

H[joint_num].homed = 0;

H[joint_num].joint_in_sequence = 0;

joint->free_tp.enable = 0;

H[joint_num].home_state = HOME_IDLE;

H[joint_num].index_enable = 0;

}

immediate_state = 1;

break;

ran it.

prints did not show up.

Seems like I'm either

1. running the old version of linuxcnc that was installed by default. dont think so as compiling changes it? still seeing 2.9.2 which makes me question (should it be 2.10?)

2. not ever getting to that code somehow...dont think this is it as it in the only place in the source code i can find that error.

3. getting to that code but the prints are not going through cause I'm misunderstanding how they work.

Any help would be great!

Thanks

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4613

- Thank you received: 2042

$ source ../scripts/rip-environment

$ linuxcnc

Please Log in or Create an account to join the conversation.

- jimmyrig

- Offline

- Premium Member

-

- Posts: 130

- Thank you received: 40

Still having the same homing issue and error message not showing up. I am probably not understanding the homing code well enough. Will look at again tonight

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

/* check for reached end of move */

if (! (&joints[jno])->free_tp.active) {

/* reached end of move without hitting switch */

(&joints[jno])->free_tp.enable = 0;

rtapi_print_msg(RTAPI_MSG_ERR,_("j%d end of move in home state %d, homing aborted"),jno, H[jno].home_state);

for (int j = 0; j < all_joints; j++) {

if (!H[j].homed) {

H[j].home_state = HOME_ABORT;

}

}

return 1; // abort reqd

}

Please Log in or Create an account to join the conversation.

- jimmyrig

- Offline

- Premium Member

-

- Posts: 130

- Thank you received: 40

Was wiring things up today and bricked my 7i96 when uploading firmware. Luckly i had a 7i96s on backup which i would have needed anyways for the BOB. Sending it back to Mesa, they will flash it for free (+shipping). Thanks Mesa!

On another note what's the process for editing the UI? seems like the files are under the /lib folder. load them up in qt, edit and restart? I'm sure its more involved than that but not sure where to begin.

looking at adding an axis for the rotary (A) and bar feed (U) and need corresponding home buttons and read outs.

was also thinking of playing around with blue line thickness that shows torch travel between cuts. Sometimes they can be hard to find if needing to restart.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

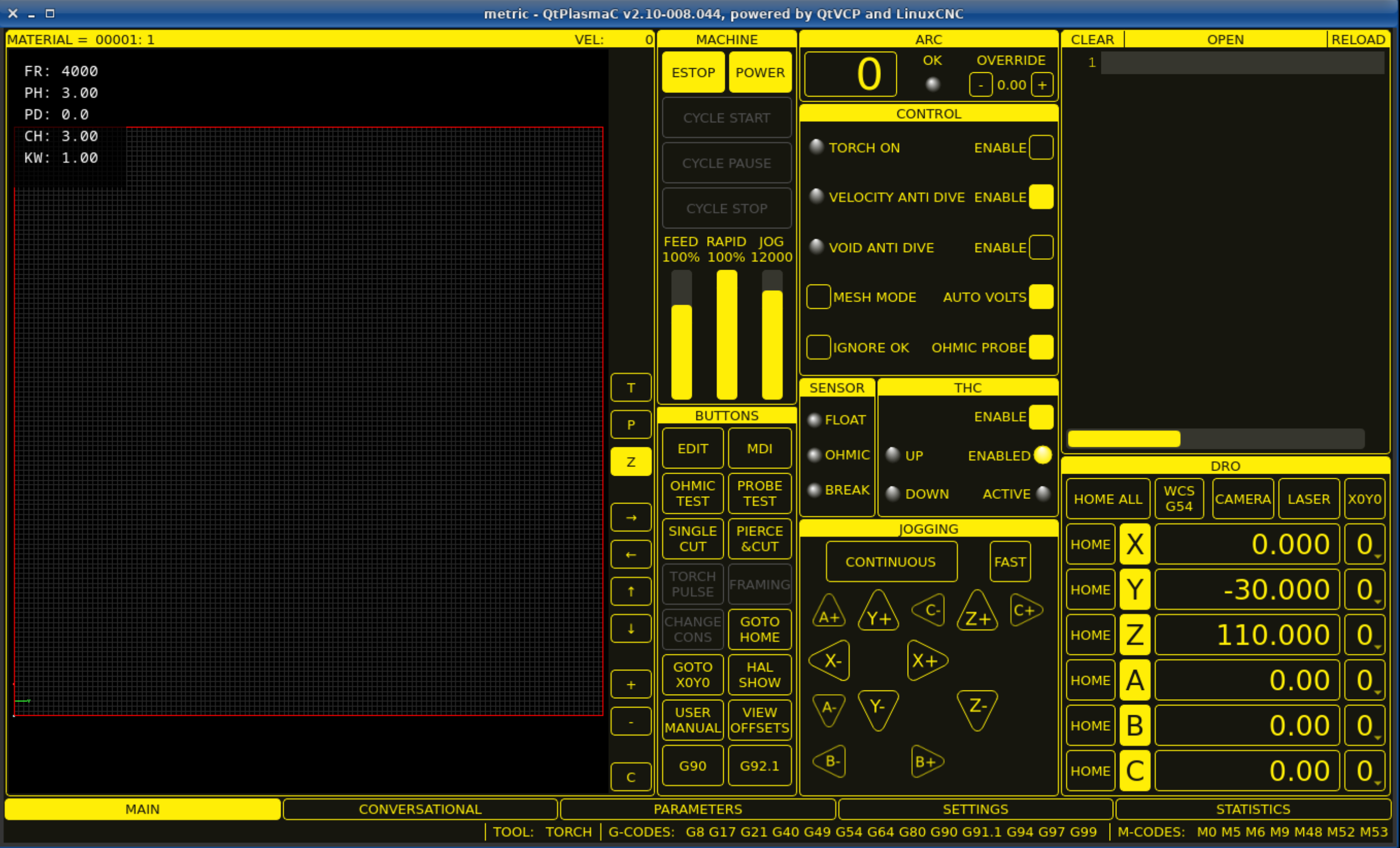

The A axis dro and buttons will appear if it is a valid axis in the config, currently XYZABC axes are catered for.On another note what's the process for editing the UI? seems like the files are under the /lib folder. load them up in qt, edit and restart? I'm sure its more involved than that but not sure where to begin.

looking at adding an axis for the rotary (A) and bar feed (U) and need corresponding home buttons and read outs.

For customising the UI, it is best to do it with a USER_COMMAND_FILE in python if possible as this will not get overwritten by any future updates. If the update issue doesn't bother you then the UI is a Qt Designer file and the handler file is a python file.

linuxcnc.org/docs/devel/html/plasma/qtpl...#_custom_python_code

The preview uses the QtVCP GCodeGraphics widget, I think you can change the colours but not the thickness. You may need to dig deeper for that.was also thinking of playing around with blue line thickness that shows torch travel between cuts. Sometimes they can be hard to find if needing to restart.

linuxcnc.org/docs/devel/html/gui/qtvcp-w...idgets:gcodegraphics

Attachments:

Please Log in or Create an account to join the conversation.

- jimmyrig

- Offline

- Premium Member

-

- Posts: 130

- Thank you received: 40

Went to run a file generated from sheetcam and got "g92 offsets are not allowed" error. Documentation seems to want a g38 instead of a g92.

Including the test file and sheetcam post, sent Les a link to this as well. Not sure which side this lies (should g92 be enabled when tube cutting is 1 or should sheetcam probe with g38)

Please Log in or Create an account to join the conversation.

- jimmyrig

- Offline

- Premium Member

-

- Posts: 130

- Thank you received: 40

Please Log in or Create an account to join the conversation.

- User Interfaces

- Plasmac

- qtplasmac 2.10 arc ok, thcad thc, and Thcad Ohmic troubleshooting help needed.