qtdragon - probing issues

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3970

15 May 2023 21:08 #271424

by rodw

The probe signal won't be triggered (on lost contact) until the probe is back sitting on its 3 legs

and a much lower speed can be used for those few microns so the distance travelled in a servo cycle thread is much less.

In theory you should be left with the lobularity error plus the distance per servo cycle which should be in sub microns (which can be slower)

We always probe away on the final probe move on plasma cutters when probing for the surface.

And we do account for switch/probe hysteresis but using a probe away strategy and an ohmic (electric contact) probe basically eliminates the hysteresis.

Replied by rodw on topic qtdragon - probing issues

This is why I think G38.4 probe away will yield more accurate results.I would think that the physical latch distance must be accounted for.

When the probe touches the material, it doesn't trip right away.

You must move enough to break the contact.

The probe signal won't be triggered (on lost contact) until the probe is back sitting on its 3 legs

and a much lower speed can be used for those few microns so the distance travelled in a servo cycle thread is much less.

In theory you should be left with the lobularity error plus the distance per servo cycle which should be in sub microns (which can be slower)

We always probe away on the final probe move on plasma cutters when probing for the surface.

And we do account for switch/probe hysteresis but using a probe away strategy and an ohmic (electric contact) probe basically eliminates the hysteresis.

The following user(s) said Thank You: Roguish

Please Log in or Create an account to join the conversation.

- Roguish

-

- Offline

- Elite Member

-

Less

More

- Posts: 297

- Thank you received: 31

15 May 2023 23:09 #271431

by Roguish

Replied by Roguish on topic qtdragon - probing issues

ya never know 'til ya try it.

i'll see if I can modify the famous p-hole.ncg (by cradek)

it does a double touch. i'll try and change the 2nd touch to a G38.4 and checkout my bearing diameter again. maybe it'll get more accurate.....

i'll see if I can modify the famous p-hole.ncg (by cradek)

it does a double touch. i'll try and change the 2nd touch to a G38.4 and checkout my bearing diameter again. maybe it'll get more accurate.....

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7291

- Thank you received: 2128

16 May 2023 01:56 #271433

by cmorley

The hole calibration does a regular X and Y probe, then does it again with the calculated center.

So far so good.

Then it calculates the X or Y or the average of both based on the difference from the calibration diameter hint (reported as delta in status).

Somehow calibration offset is used in that calculation. Are you to put the 'delta' into the calibration offset to zero out the error?

But it doesn't seem to actually use any calibration offset when doing regular probing.

Maybe it never got finished.

Replied by cmorley on topic qtdragon - probing issues

I looked at the code for calibration and I don't really get the intent.As for calibration, qtdragon VersaProbe does not have a routine for that. Probe Basic does, but I'm not sure how it operates, or if it is correct or not. I have done some searching for calibration routines and have found a few. So far they are primarily accounting for off-centerness.

Wish I had one of those super good Renishaws.

The hole calibration does a regular X and Y probe, then does it again with the calculated center.

So far so good.

Then it calculates the X or Y or the average of both based on the difference from the calibration diameter hint (reported as delta in status).

Somehow calibration offset is used in that calculation. Are you to put the 'delta' into the calibration offset to zero out the error?

But it doesn't seem to actually use any calibration offset when doing regular probing.

Maybe it never got finished.

The following user(s) said Thank You: Roguish

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3970

16 May 2023 04:10 #271436

by rodw

Replied by rodw on topic qtdragon - probing issues

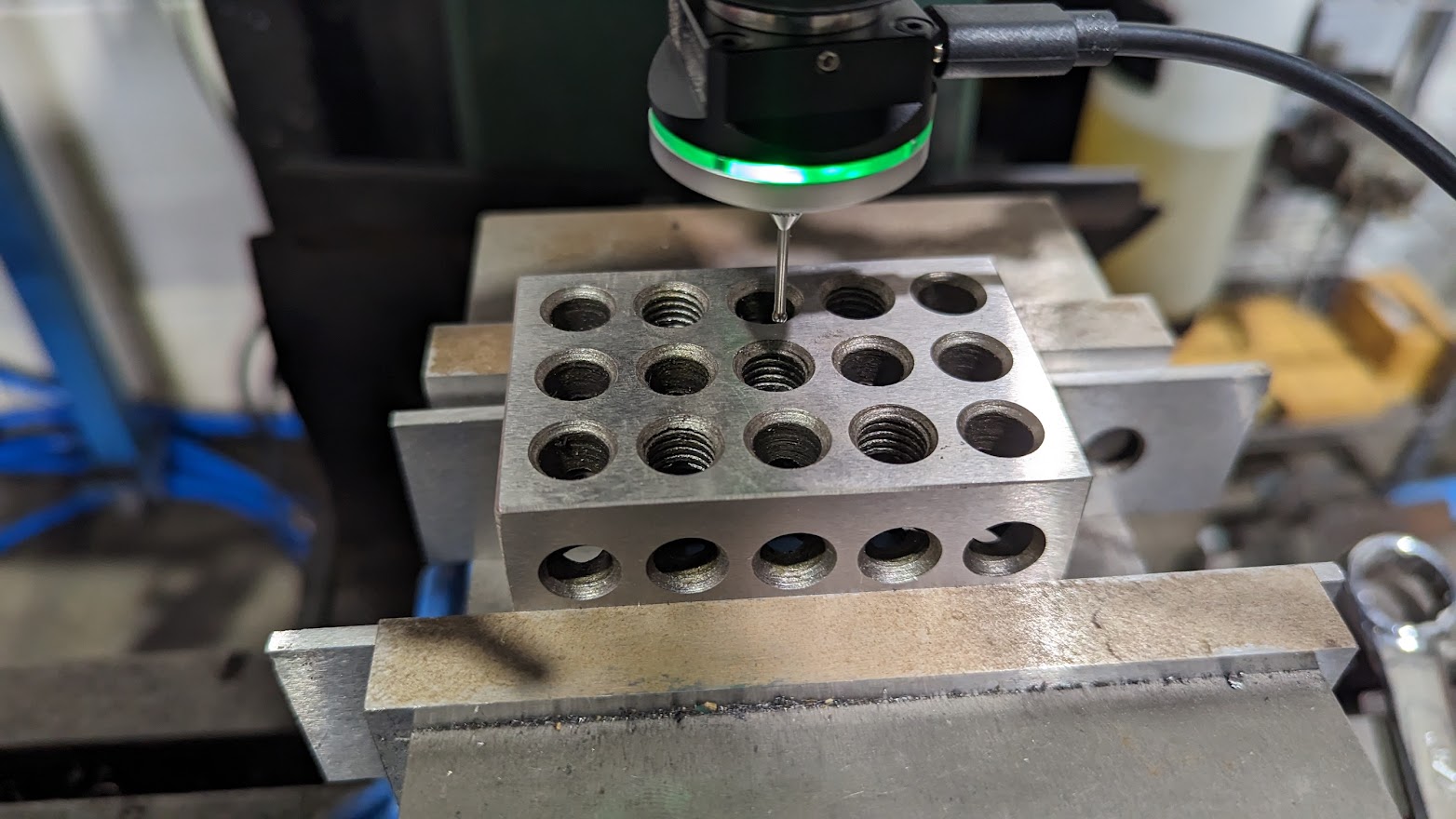

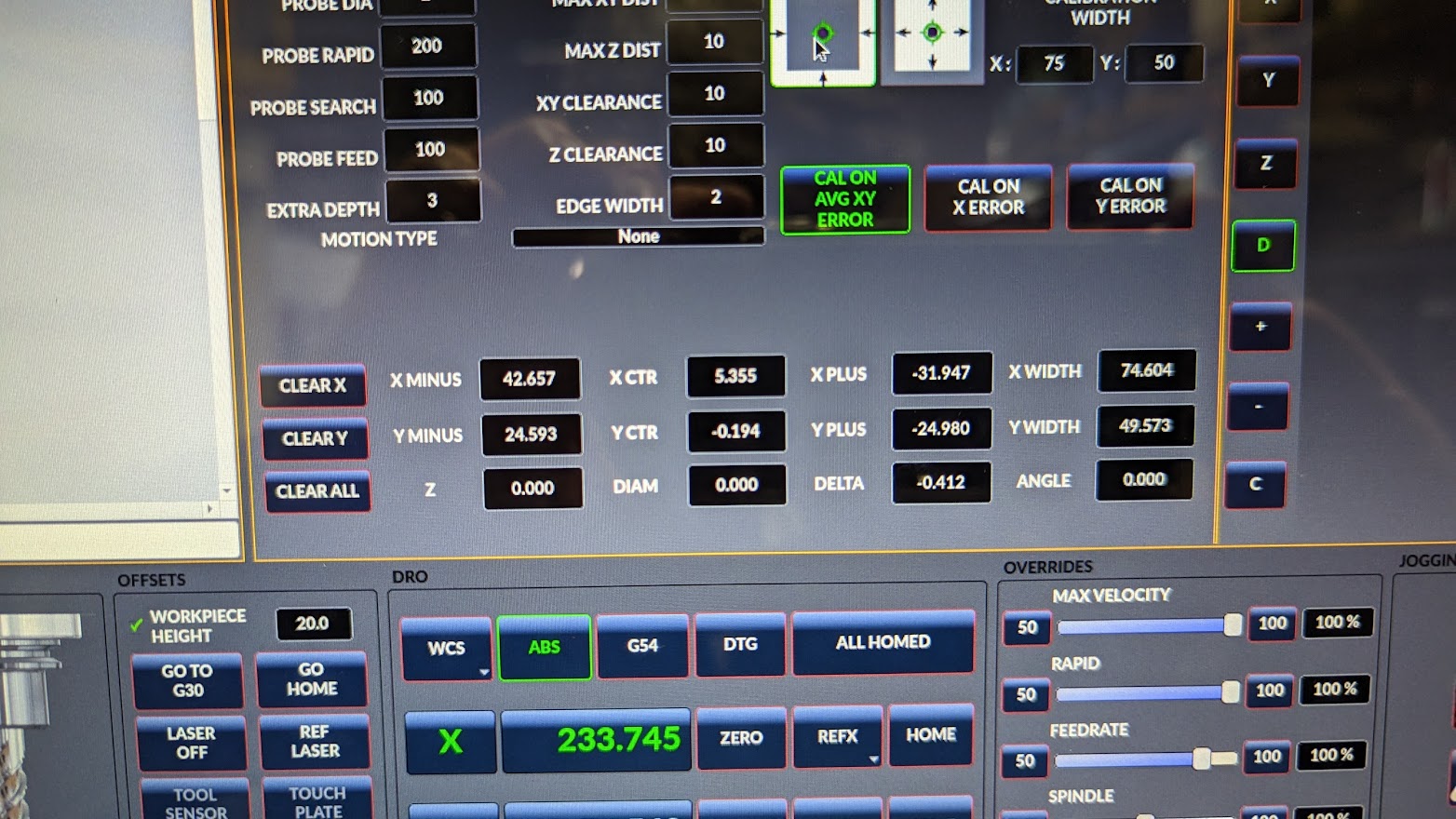

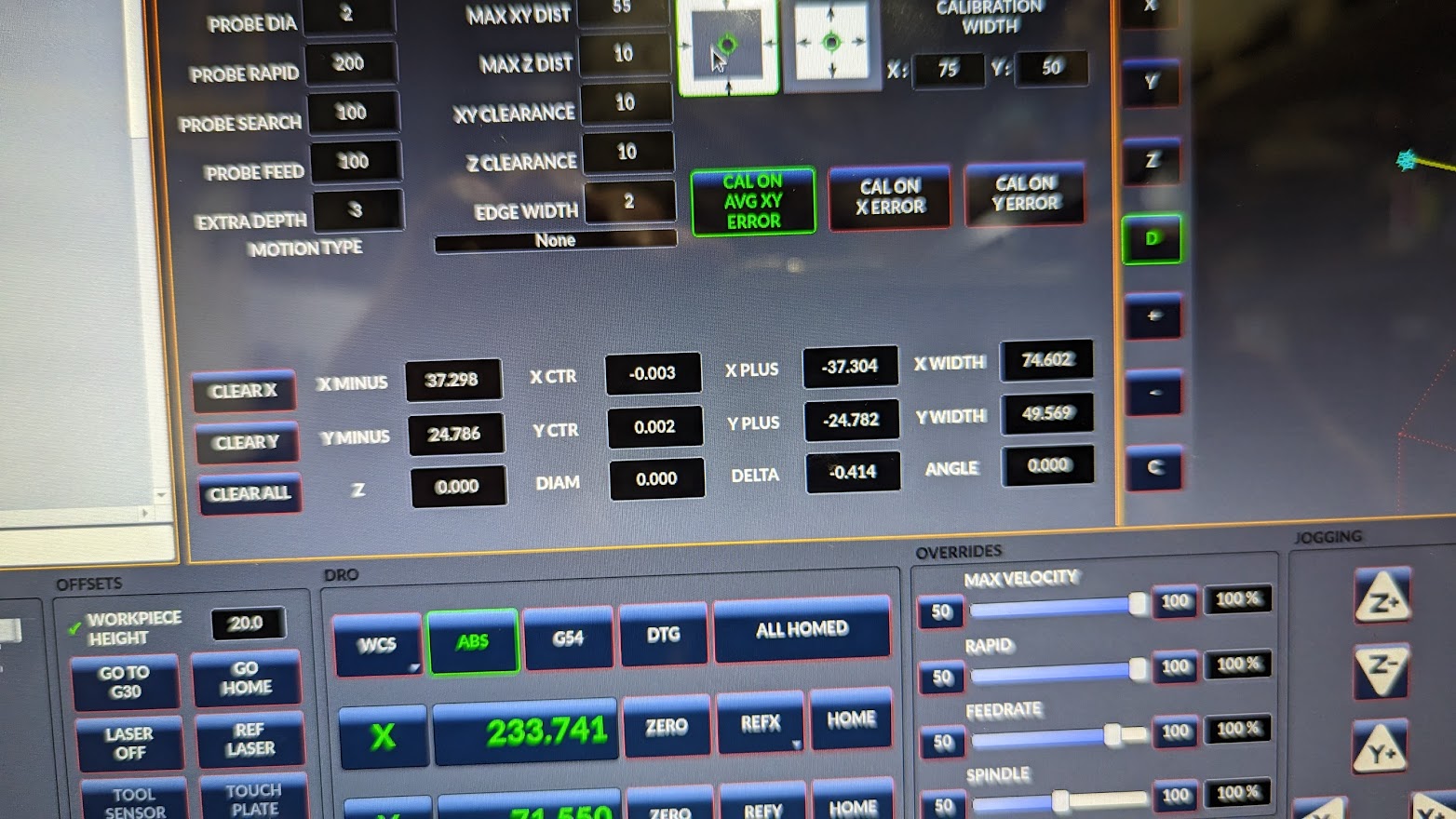

The calibration seems OK. I probed a metric 123 block (50mm x 75mm)

First probe

Second probe from exact centre

It seems you need to probe twice to centre the probe first. But the delta is close to the difference from the X & Y widths.

Looking at the second probe, the measurements are consistent but out by about 0.2mm. I wonder if this is the latching distance/switch hysteresis? It would be intresting to see it with G38.4 becasue I seem to remember it was about 0.2mm difference.

First probe

Second probe from exact centre

It seems you need to probe twice to centre the probe first. But the delta is close to the difference from the X & Y widths.

Looking at the second probe, the measurements are consistent but out by about 0.2mm. I wonder if this is the latching distance/switch hysteresis? It would be intresting to see it with G38.4 becasue I seem to remember it was about 0.2mm difference.

Attachments:

The following user(s) said Thank You: Roguish

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3970

16 May 2023 04:19 #271437

by rodw

Replied by rodw on topic qtdragon - probing issues

The inside corner probinfg is still worng. See video

photos.app.goo.gl/CtHjZJhMTHLYu8Zx8

Based on the initial move on start. the probe should be situated near the corner but out a few mm from the corner towards the front eg x -10, Y -10

I did run it from the outside of the left edge but it almost seemed like it as confusing the X direction with the Y direction.

photos.app.goo.gl/CtHjZJhMTHLYu8Zx8

Based on the initial move on start. the probe should be situated near the corner but out a few mm from the corner towards the front eg x -10, Y -10

I did run it from the outside of the left edge but it almost seemed like it as confusing the X direction with the Y direction.

The following user(s) said Thank You: Roguish

Please Log in or Create an account to join the conversation.

- Roguish

-

- Offline

- Elite Member

-

Less

More

- Posts: 297

- Thank you received: 31

16 May 2023 14:25 - 16 May 2023 17:50 #271458

by Roguish

Replied by Roguish on topic qtdragon - probing issues

Chris, I'm not completely sure yet what a calibration routine does. i'm looking at several that I have found. reading through them and maybe trying them out. the routine in Probe Basic may not be finished, or actually function correctly. guess we're debugging....again. better late than never.

I finally got my inexpensive probe working. Interestingly it looks identical to Rodw's in his pictures.....

So i'll be able to check on some of what I mentioned previously.

I also figured out how to see underscores in geany editor when looking at code..... really helps.

.

.

.

**********************

OK, did some testing. using the newer probe with a 2mm ball, the bearing bore ID is again measured at about 0.005in too big. that's with a debounce time of either 2 or 5. that's using qtdragon and versa.

more testing.. in an ncggui file, probe_hole6.ncg, which is based on cradek's p-hole, and works well, I changed the 'slow probes' to 38.4.

doesn't really work. when it reaches the first 38.4 line it touches the bearing id and just stops..... not sure what's happening.

Attached that file here..

Rodw, could you share a working 38.4 routine so I can see how you use it correctly? thanks.

I finally got my inexpensive probe working. Interestingly it looks identical to Rodw's in his pictures.....

So i'll be able to check on some of what I mentioned previously.

I also figured out how to see underscores in geany editor when looking at code..... really helps.

.

.

.

**********************

OK, did some testing. using the newer probe with a 2mm ball, the bearing bore ID is again measured at about 0.005in too big. that's with a debounce time of either 2 or 5. that's using qtdragon and versa.

more testing.. in an ncggui file, probe_hole6.ncg, which is based on cradek's p-hole, and works well, I changed the 'slow probes' to 38.4.

doesn't really work. when it reaches the first 38.4 line it touches the bearing id and just stops..... not sure what's happening.

Attached that file here..

Rodw, could you share a working 38.4 routine so I can see how you use it correctly? thanks.

Last edit: 16 May 2023 17:50 by Roguish.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3970

16 May 2023 19:46 #271465

by rodw

Replied by rodw on topic qtdragon - probing issues

Rougish, I shared a Z probe with 38.4 earlier in this thread.

forum.linuxcnc.org/qtvcp/48995-qtdragon-...ssues?start=0#270612

forum.linuxcnc.org/qtvcp/48995-qtdragon-...ssues?start=0#270612

The following user(s) said Thank You: Roguish

Please Log in or Create an account to join the conversation.

- Roguish

-

- Offline

- Elite Member

-

Less

More

- Posts: 297

- Thank you received: 31

16 May 2023 22:24 - 16 May 2023 22:30 #271478

by Roguish

Replied by Roguish on topic qtdragon - probing issues

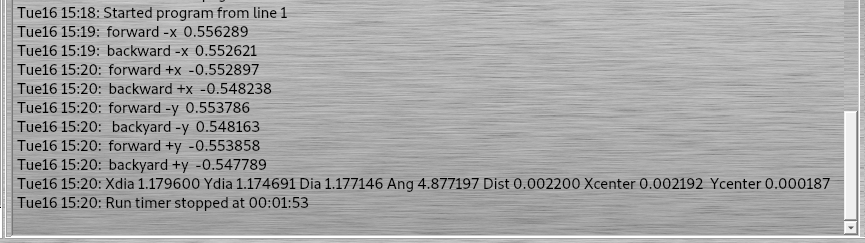

rodw, thanks. I modified the probe_hole6.ncg (attached here) to include a g38.4 (reverse probe) following the forward slow probe.\

after each touch, I included a debug statement so it'd write out to status the data of both probes.

interesting. all 4 probes, +y,-y,+x,-x, show about 0.004 inch difference.......that's significant.

see the file and pictures.

and it's a 30mm ID bearing

.

the file is set to be used in ncggui, even in qtdragon. very handy.

.

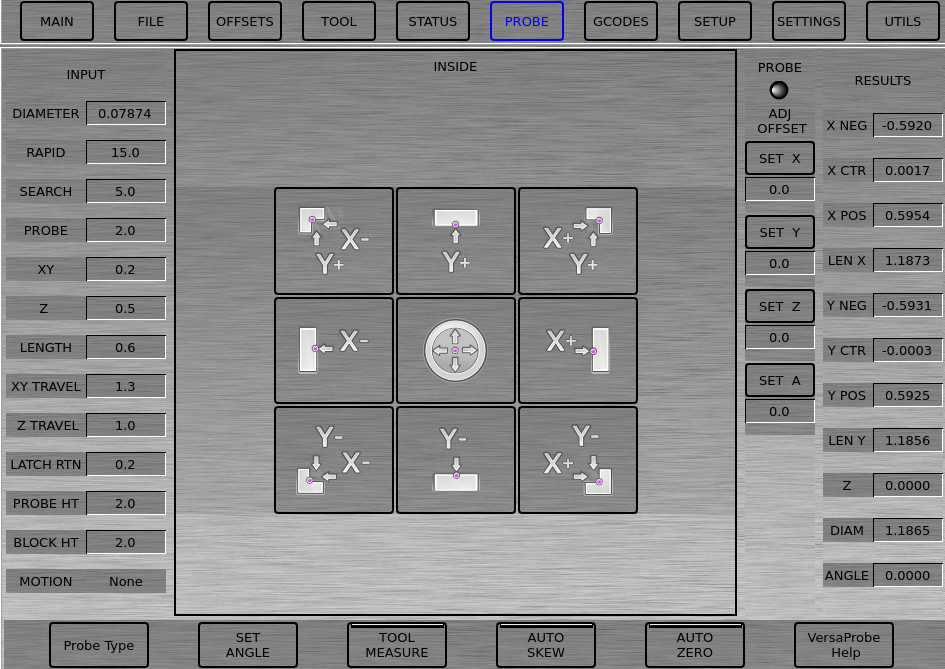

. and here's the regular VersaProbe ID.

.

after each touch, I included a debug statement so it'd write out to status the data of both probes.

interesting. all 4 probes, +y,-y,+x,-x, show about 0.004 inch difference.......that's significant.

see the file and pictures.

and it's a 30mm ID bearing

.

the file is set to be used in ncggui, even in qtdragon. very handy.

.

. and here's the regular VersaProbe ID.

.

Last edit: 16 May 2023 22:30 by Roguish.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3970

16 May 2023 23:15 #271488

by rodw

Replied by rodw on topic qtdragon - probing issues

From your print statement, you have a diameter of 29.8995084 ( round to 3 decimals = 29.900

What did th eoriginal probing routine calculate? You need to look at X & Y after an initial probe to centre it

I wonder what would happen if you changed your probe diameter from say 2mm to 2.005

What did th eoriginal probing routine calculate? You need to look at X & Y after an initial probe to centre it

I wonder what would happen if you changed your probe diameter from say 2mm to 2.005

The following user(s) said Thank You: Roguish

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7291

- Thank you received: 2128

17 May 2023 00:49 #271492

by cmorley

For inside probing you should set the probe at the inside corner.

First move will be -y by edge distance and at same time +x by xy clearance

looks like you had edge distance at 1mm? and clearance at 10mm?

If so then the move looked right.

again a little hard to see at the angle nut looked like it moved about 10mm to the right and a much smaller distance towards the camera. i think if you had set the probe starting point on the inside corner then it would not have failed.

Can you confirm this for me?

Replied by cmorley on topic qtdragon - probing issues

A little hard to see but it looks to me you started with the probe on the outside corner.The inside corner probinfg is still worng. See video

photos.app.goo.gl/CtHjZJhMTHLYu8Zx8

Based on the initial move on start. the probe should be situated near the corner but out a few mm from the corner towards the front eg x -10, Y -10

I did run it from the outside of the left edge but it almost seemed like it as confusing the X direction with the Y direction.

For inside probing you should set the probe at the inside corner.

First move will be -y by edge distance and at same time +x by xy clearance

looks like you had edge distance at 1mm? and clearance at 10mm?

If so then the move looked right.

again a little hard to see at the angle nut looked like it moved about 10mm to the right and a much smaller distance towards the camera. i think if you had set the probe starting point on the inside corner then it would not have failed.

Can you confirm this for me?

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 0.169 seconds