- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

13 Jun 2020 13:01 #171426

by Grotius

Replied by Grotius on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Hi Tom,

If i look at your value i suggest it could be a calculaled value of -97?

If i look at your value i suggest it could be a calculaled value of -97?

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

13 Jun 2020 13:11 #171431

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Yes, but on 3 meters of travel, that small difference is noticeable.Hi Tom,

If i look at your value i suggest it could be a calculaled value of -97?

The following user(s) said Thank You: Grotius

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

13 Jun 2020 13:26 #171440

by Grotius

Replied by Grotius on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

I have a scale off 93.6361 for my plasma cutters.

So we are close.

So we are close.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

13 Jun 2020 13:44 #171445

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Yup that is quite close.

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

13 Jun 2020 13:47 #171446

by bbsr_5a

Replied by bbsr_5a on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

you only will find out the scale if you set it right if you cut a scare on every corner of your sheet id like to start at 60x60mm

messure all and then 80x80mm

if you are still off then you missed somthing

messure all and then 80x80mm

if you are still off then you missed somthing

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

13 Jun 2020 13:52 #171449

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

At 60 or 80mm the small errors are not noticeable, i check at the full machine travel, several times to make sure.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

17 Jun 2020 18:22 #171915

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

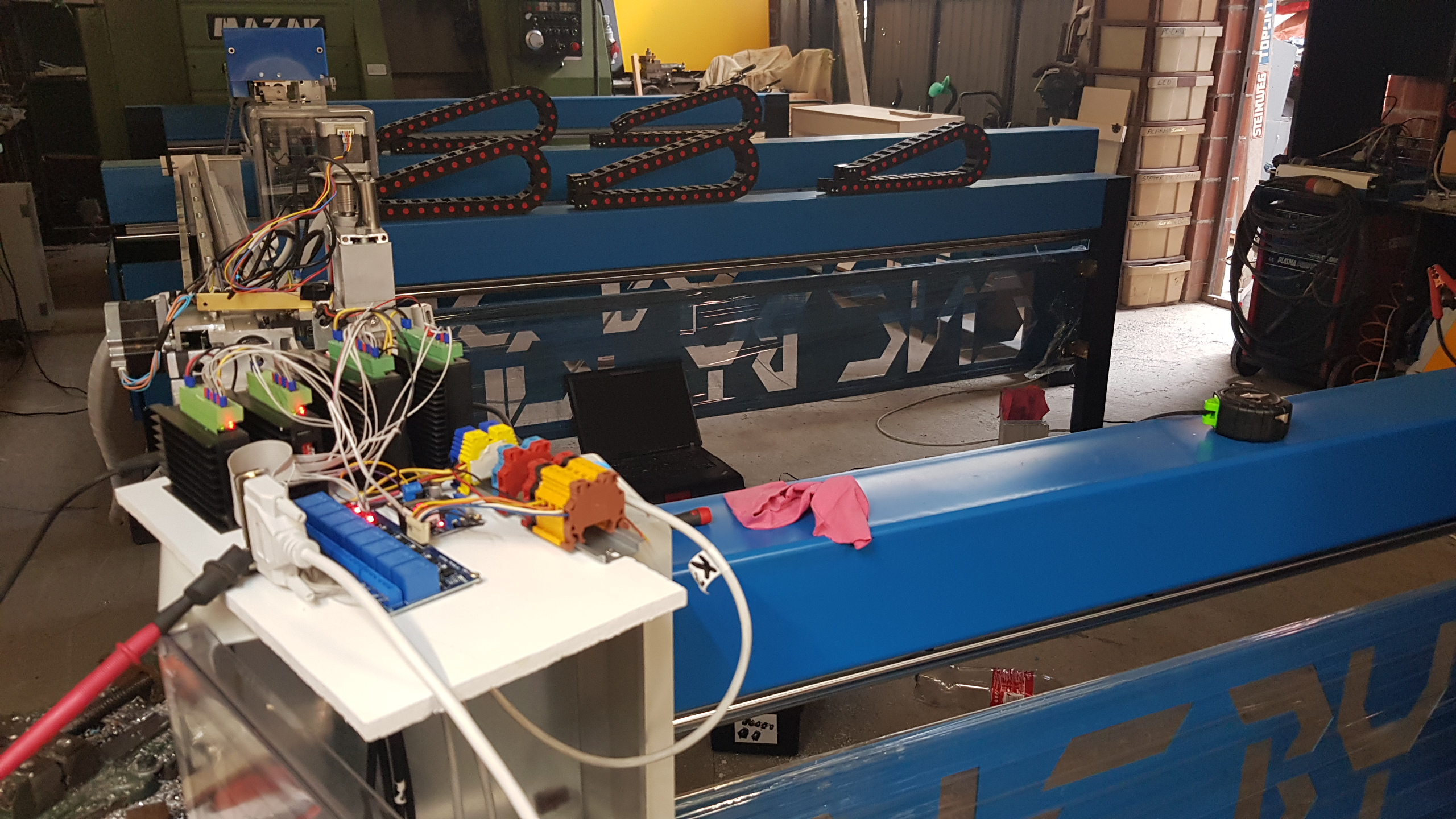

Smaller machine update:

- Alu gantry, mounted,

- rails, mounted and aligned,

- X axis motor and belt, mounted and adjusted for tension,

- X axis home and both limits sensor, mounted, no limits set yet,

- Z axis assembly, mounted and aligned,

- Cross laser mounted to the Z axis body,

- Wiring for Y axis from one side to the other routed through the aluminium,

- Wiring of the Z and X axis sensors, motors, floating switch, laser and LED's done,

Remains:

- Wiring from the gantry to the Z and X assembly,

- Wiring all the stuff together at one side of the machine,

- Putting the electronics and power and relays in a box and bolting it to the gantry,

- Bolting front and back panels in place,

- Making a plastic cap for the Z axis,

waiting for the drag chain till Saturday, hopefully.

Got a new helper today, or nuisance, depending on how you look at it :

And the current state of the Z axis on the smaller machine:

Going to drill some holes on the gantry and route the wiring now.

Regards,

Tom.

- Alu gantry, mounted,

- rails, mounted and aligned,

- X axis motor and belt, mounted and adjusted for tension,

- X axis home and both limits sensor, mounted, no limits set yet,

- Z axis assembly, mounted and aligned,

- Cross laser mounted to the Z axis body,

- Wiring for Y axis from one side to the other routed through the aluminium,

- Wiring of the Z and X axis sensors, motors, floating switch, laser and LED's done,

Remains:

- Wiring from the gantry to the Z and X assembly,

- Wiring all the stuff together at one side of the machine,

- Putting the electronics and power and relays in a box and bolting it to the gantry,

- Bolting front and back panels in place,

- Making a plastic cap for the Z axis,

waiting for the drag chain till Saturday, hopefully.

Got a new helper today, or nuisance, depending on how you look at it :

And the current state of the Z axis on the smaller machine:

Going to drill some holes on the gantry and route the wiring now.

Regards,

Tom.

Attachments:

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

20 Jun 2020 14:07 #172157

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Drag chains are here, the electronics for the smaller one are nearly finished, so all in all the finish line is close, very close.

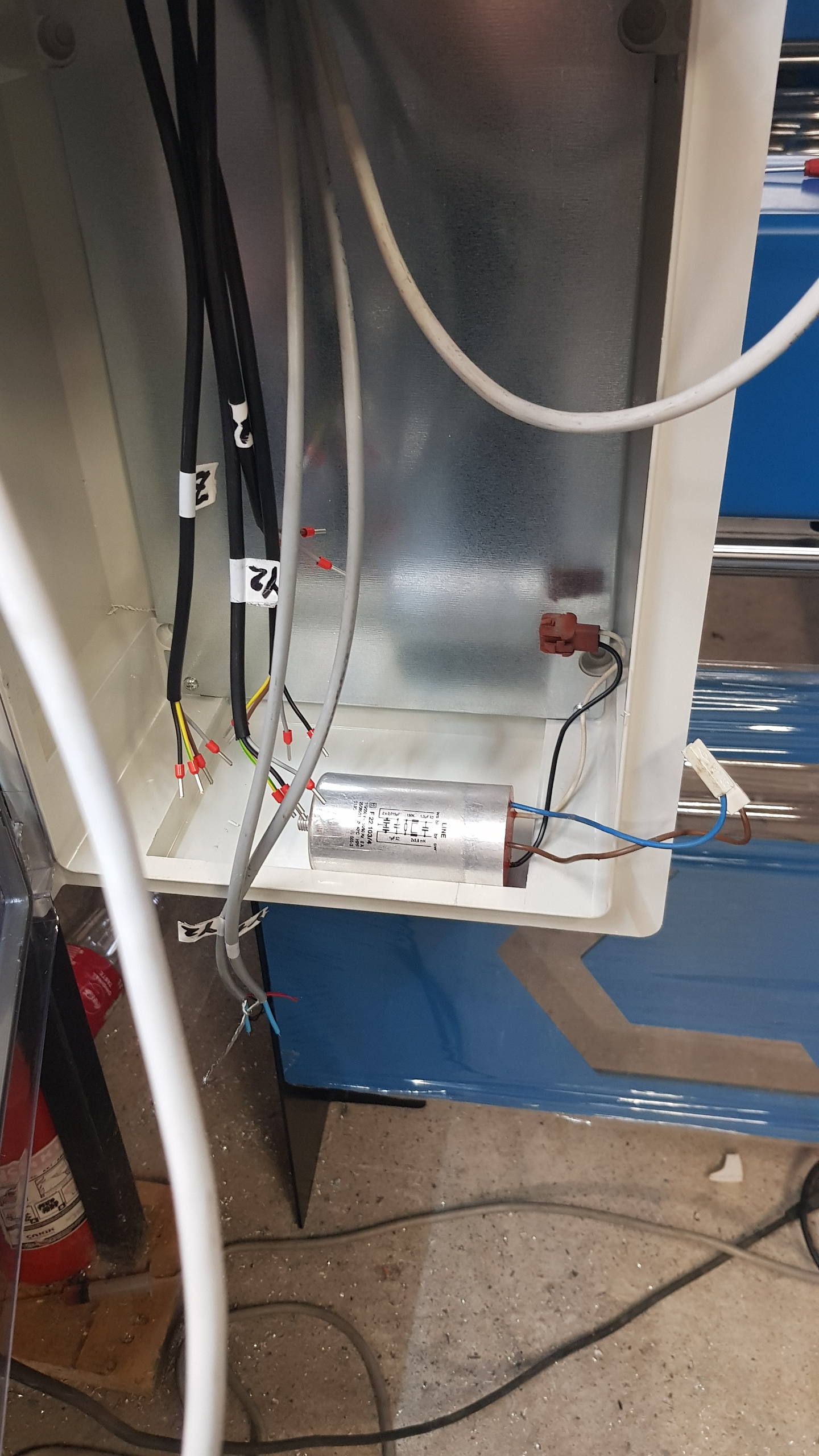

This is the last line filter i have, and it's round so mounting it only by zip ties, mounting it by the screw as it is supposed to leaves it blocking 1/4 of electronics:

Also got bit by that small fluffy dog today while playing with it, has bloody sharp teeth, literally bloody !

On to wiring and testing and tuning .... and i have no more 7i92M so this one is going to be used with a parallel port or Mesa 5i25 ( have 1) or Mesa 6i25 (have 2) for now. Last time i tried using Mesa 6i25 and 7i92 with software encoder something was not right, must have missed something in hal, so will have to try that again as using hardware encoder works perfectly, but it locks 3 input pins forcing me to use the second IO port on them for limit switches and using 2 thick cables is not very elegant for the 6i25. 7i92 on the other hand is no problem as it is inside the same case, so adding 3 more wire to the header is simple enough. I did order another 7i92 but to late, so again waiting .......

Regards,

Tom.

This is the last line filter i have, and it's round so mounting it only by zip ties, mounting it by the screw as it is supposed to leaves it blocking 1/4 of electronics:

Also got bit by that small fluffy dog today while playing with it, has bloody sharp teeth, literally bloody !

On to wiring and testing and tuning .... and i have no more 7i92M so this one is going to be used with a parallel port or Mesa 5i25 ( have 1) or Mesa 6i25 (have 2) for now. Last time i tried using Mesa 6i25 and 7i92 with software encoder something was not right, must have missed something in hal, so will have to try that again as using hardware encoder works perfectly, but it locks 3 input pins forcing me to use the second IO port on them for limit switches and using 2 thick cables is not very elegant for the 6i25. 7i92 on the other hand is no problem as it is inside the same case, so adding 3 more wire to the header is simple enough. I did order another 7i92 but to late, so again waiting .......

Regards,

Tom.

Attachments:

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

20 Jun 2020 20:54 #172189

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Got the electronics sorted and mounted inside the case, did some test with a plain config to set the motion and limits/home properly, some fine tuning is needed, so should be finished in a day or two, well both of them should be finished as the bigger one needs just the drag chain and the water table, but water tables will have to wait as if i build them inside the shop i will not be able to get them out !

Here is a boring video of it moving on it's own attached to a parallel port for now:

Hmmm Note 9 camera making some jumps while recording, did not see those on the Note 8. not even at 4K recordings! Strange ....

Regards,

Tom.

Here is a boring video of it moving on it's own attached to a parallel port for now:

Hmmm Note 9 camera making some jumps while recording, did not see those on the Note 8. not even at 4K recordings! Strange ....

Regards,

Tom.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

22 Jun 2020 15:30 #172361

by tommylight

Tomorrow my brother comes with some of his employees to do some video shootings and some pictures that will look better than the Note 8/9 ones i do. Too bad i do not have the tables to do some cutting while at it, would have been much better as people like sparks, something to do with genetics and our predecessors looking at fire a lot !??

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Everything is done, except for the orange marked line.Remains:

- Wiring from the gantry to the Z and X assembly,

- Wiring all the stuff together at one side of the machine,

- Putting the electronics and power and relays in a box and bolting it to the gantry,

- Bolting front and back panels in place, Not done yet

- Making a plastic cap for the Z axis,

waiting for the drag chain till Saturday, hopefully.

Tomorrow my brother comes with some of his employees to do some video shootings and some pictures that will look better than the Note 8/9 ones i do. Too bad i do not have the tables to do some cutting while at it, would have been much better as people like sparks, something to do with genetics and our predecessors looking at fire a lot !??

Please Log in or Create an account to join the conversation.

- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Time to create page: 0.232 seconds