- Other Stuff

- Show Your Stuff

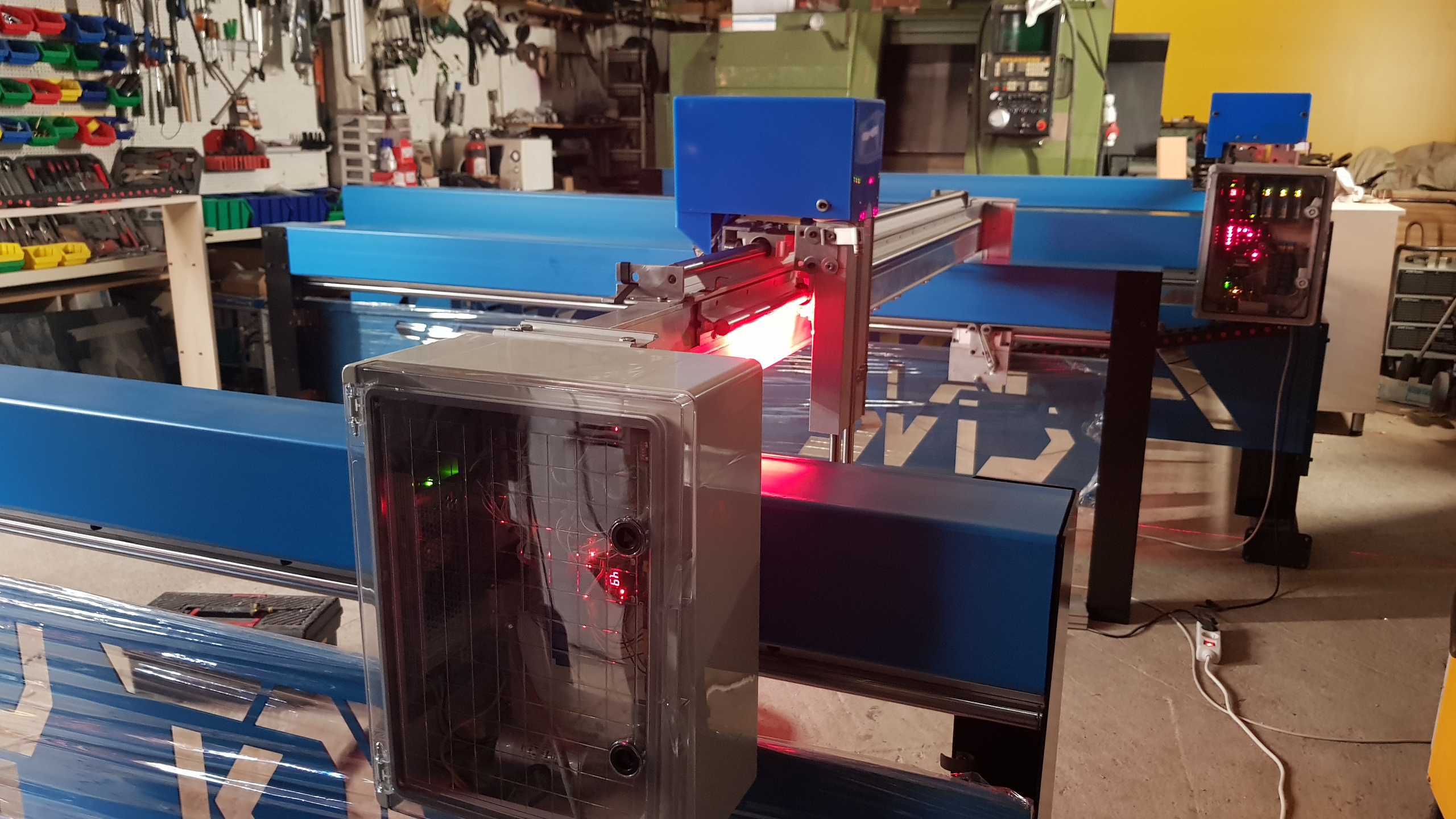

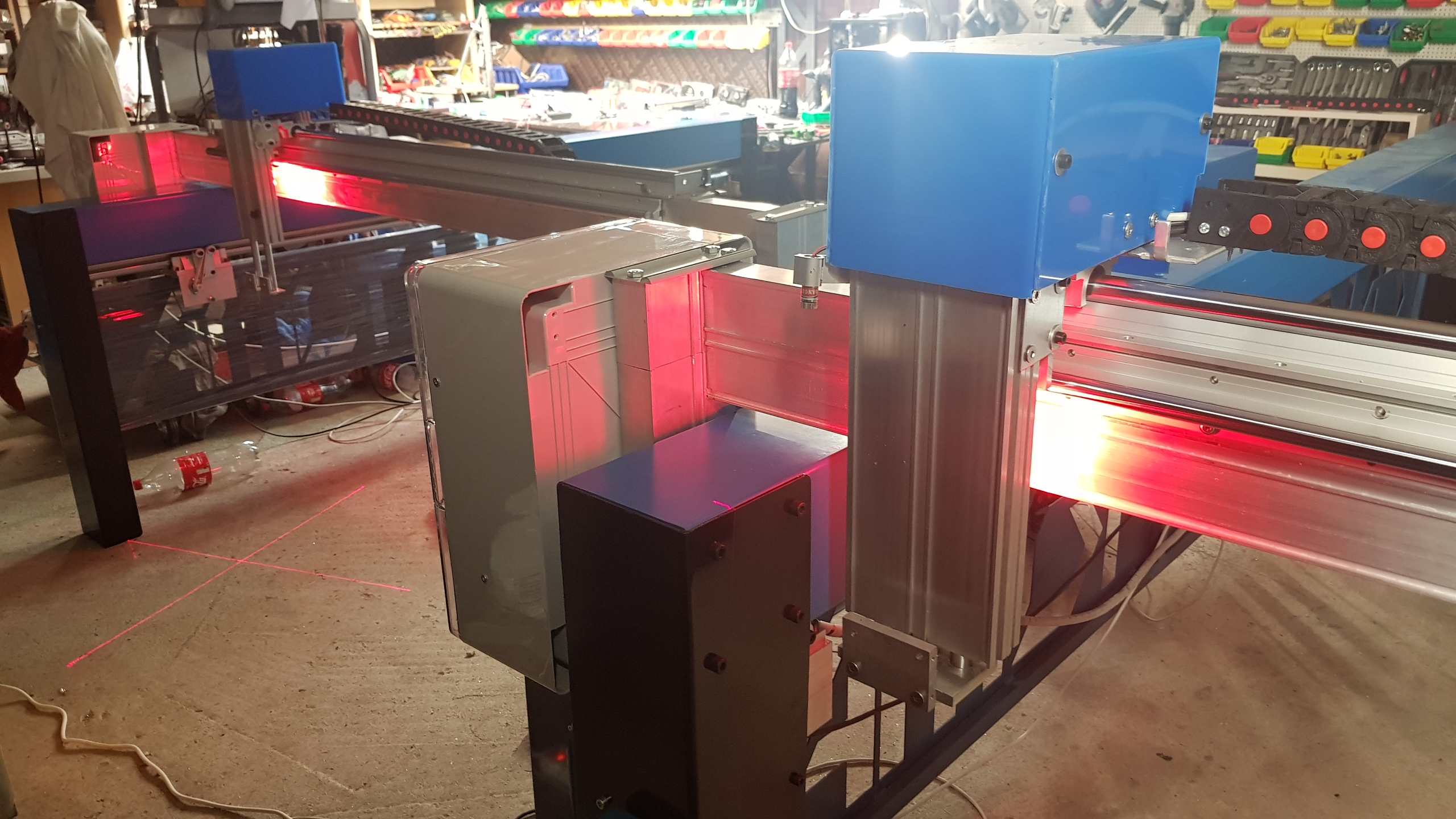

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

- tommylight

-

Topic Author

Topic Author

- Offline

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

24 Jun 2020 22:33 #172644

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Attachments:

The following user(s) said Thank You: phillc54, Clive S, tecno

Please Log in or Create an account to join the conversation.

- shpatb

-

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

25 Jun 2020 20:30 #172751

by shpatb

Replied by shpatb on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

They are looking awesome, Great job uncle Tom ..

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Offline

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

25 Jun 2020 21:13 #172757

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Thank you.They are looking awesome, Great job uncle Tom ..

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3914

25 Jun 2020 21:49 #172758

by rodw

Replied by rodw on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Tommy, I went back though your posts but could not see a photo of the drive on your Y axis. So You've used two round rails on each side?

It would be good to see some closeups Uncle Tom!

It would be good to see some closeups Uncle Tom!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Offline

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

25 Jun 2020 22:48 #172761

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Rails, one per Y side:

forum.linuxcnc.org/show-your-stuff/38547...build?start=0#161039

Drive train on one Y side, same on the other just mirrored:

forum.linuxcnc.org/show-your-stuff/38547...uild?start=10#165577

forum.linuxcnc.org/show-your-stuff/38547...build?start=0#161039

Drive train on one Y side, same on the other just mirrored:

forum.linuxcnc.org/show-your-stuff/38547...uild?start=10#165577

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3914

26 Jun 2020 00:24 #172768

by rodw

Replied by rodw on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Tommy thanks for that. We got a bit excited here after seeing an old scrapped machine sporting a 30mm wide belt and I was wondering if I could convert the spaceship to a belt drive on the X axis across the gantry. The ebay special rack and pinion is not really a great bit of gear!

I was always worried the round rail would allow axial rotation so never really considered using them. I thought you'd need two each side.

I was always worried the round rail would allow axial rotation so never really considered using them. I thought you'd need two each side.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Offline

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

26 Jun 2020 10:04 - 26 Jun 2020 10:07 #172786

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Wide belt is much better for plasma, especially for moving lighter parts of the machine, up to a certain length, but that is very dependant on the belt having steel or kevlar reinforcement, the price difference is negligible so i never use non reinforced belts.

Already seen two industrial plasma machines using belts on the X axis.

The axial rotation is what makes them much easier to install and adjust, they do not have the tolerances and the weight capability of the square rails, but for plasma with a light gantry anything over 16mm is plenty.

Next machine i build will have SBR25 on the sides and HGR20 on the X axis, a single one. That is if i can make some space to build a 6.5X2.5 meter machine with 4th axis.

Edit:

Also regarding belts, Andy mentioned "servo belts" and that is what i was going for when building these two machines, but i never received the second shipment of the same belt, so if i do receive them, i will add them in, that will remove that little bit of flex on quick direction changes completely.

Already seen two industrial plasma machines using belts on the X axis.

The axial rotation is what makes them much easier to install and adjust, they do not have the tolerances and the weight capability of the square rails, but for plasma with a light gantry anything over 16mm is plenty.

Next machine i build will have SBR25 on the sides and HGR20 on the X axis, a single one. That is if i can make some space to build a 6.5X2.5 meter machine with 4th axis.

Edit:

Also regarding belts, Andy mentioned "servo belts" and that is what i was going for when building these two machines, but i never received the second shipment of the same belt, so if i do receive them, i will add them in, that will remove that little bit of flex on quick direction changes completely.

Last edit: 26 Jun 2020 10:07 by tommylight. Reason: More info

The following user(s) said Thank You: rodw, Aciera

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3914

26 Jun 2020 10:12 #172787

by rodw

Replied by rodw on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Tommy, thanks, I ran some rough numbers by a timing belt company here in Australia and they asked me to fill out a form which they have sent off to Optobelt in Germany to come up with a design recommendation. Their initial thought was a AT5 x 25mm wide. It will be interesting to see what comes back.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3914

26 Jun 2020 11:05 #172789

by rodw

Tommy, Ever since I built my machine and learnt about the torque handling capabilities of the HGR rails, and reviewing the engineering forces again recently, I think a single HGR 15 is all we need on any axis. HGR15 has a weight advantage over the SBR rails for mounting on the gantry.

I'm not sure what they mean by servo belts but we were talking about a long belt product. It will be interesting to see what comes back from Germany. I told them I wanted 60 m/min travel and 0.5 m/s^2 acceleration.

I'm still thinking about ways to replace my heavy rack and pinion with a belt....

Replied by rodw on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Next machine i build will have SBR25 on the sides and HGR20 on the X axis, a single one.

Tommy, Ever since I built my machine and learnt about the torque handling capabilities of the HGR rails, and reviewing the engineering forces again recently, I think a single HGR 15 is all we need on any axis. HGR15 has a weight advantage over the SBR rails for mounting on the gantry.

I'm not sure what they mean by servo belts but we were talking about a long belt product. It will be interesting to see what comes back from Germany. I told them I wanted 60 m/min travel and 0.5 m/s^2 acceleration.

I'm still thinking about ways to replace my heavy rack and pinion with a belt....

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Offline

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

26 Jun 2020 11:20 #172793

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Basically a static and a dynamic belt meshed together, so the only stretchy part is about 7 to 15cm depending on the setup:

community.carbide3d.com/t/bell-everman-servo-belt-system/10923

www.designworldonline.com/alternative-to...ilt-from-components/

community.carbide3d.com/t/bell-everman-servo-belt-system/10923

www.designworldonline.com/alternative-to...ilt-from-components/

The following user(s) said Thank You: Coachbuilder

Please Log in or Create an account to join the conversation.

- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Time to create page: 0.267 seconds