- Configuring LinuxCNC

- Advanced Configuration

- Preparation for the self-construction of a carousel changer

Preparation for the self-construction of a carousel changer

- Aciera

-

- Offline

- Administrator

-

- Posts: 4648

- Thank you received: 2068

This is odd because it works for me. (Although I'm on 2.9) There is a simulation config with 9-axis and if I remove the 'u' letter from the display section U-axis moves are no longer shown in the preview display.I have also entered the geometry in the [DISPLAY] section

GEOMETRY = X Y Z

Unfortunately the U axis still moves when I move the U axis.

Please Log in or Create an account to join the conversation.

- mgm

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 210

- Thank you received: 13

With a finished axis sim in 2.8 I can omit the U in the geometry and then the simulation moves in X anyway.

Then I made a sim based on Stepconf as XYZA and changed the A to U and lo and behold:

If the letter U is left out in the geometry, it does not move either!!!

Apparently there is a problem with the 2.8 in conjunction with a finished sim.

Thanks for the impetus to test it again in detail!

Many thanks

Then I can continue

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

Please Log in or Create an account to join the conversation.

- mgm

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 210

- Thank you received: 13

Attached is the "hal file"

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

It might not move the X axis on screen if it is not connected. (or it might, or it might depend on whether "commanded" or a "actual" is selected for display.)No, as far as I can see, the pin is already connected.

Attached is the "hal file"

Please Log in or Create an account to join the conversation.

- mgm

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 210

- Thank you received: 13

I have finished building my carousel so far.

The U Axis is mounted on it sits the carousel with geneva wheel

which is retracted and extended by a cylinder.

I have 12 pockets each equipped with 4 screw heads so that the pocket can be clearly assigned.

So like this:

0001

0011

0111

etc ...

Is the coding called gray? Is the example below a useful example for my project?

loadrt carousel pockets=10 dir=1 encoding=gray num_sense=4

#loadrt conv_float_s32 (Already loaded in sim_vmc.hal)

addf carousel.0 servo-thread

addf conv-float-s32.2 servo-thread # G-code analogue outputs are float-type

setp carousel.0.fwd-dc 0.002

net car-enable motion.digital-out-00 carousel.0.enable

net car-ready carousel.0.ready motion.digital-in-00

net car-vel carousel.0.motor-vel

net car-pos-req motion.analog-out-00 conv-float-s32.2.in

net car-pos-s32 conv-float-s32.2.out carousel.0.pocket-number

net bit0 carousel.0.sense-0

net bit1 carousel.0.sense-1

net bit2 carousel.0.sense-2

net bit3 carousel.0.sense-3

net car-lock motion.digital-out-01

net car-locked motion.digital-in-01

net arm-act motion.digital-out-02

net arm-in motion.digital-in-02

net arm-out motion.digital-in-04

net tool-release motion.digital-out-03

net tool-released motion.digital-in-03

net tool-prep-loop iocontrol.0.tool-prepare iocontrol.0.tool-prepared

net tool-change-loop iocontrol.0.tool-change iocontrol.0.tool-changed

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

I don't know what that coding would be, Gray coding follows the pattern here:I have 12 pockets each equipped with 4 screw heads so that the pocket can be clearly assigned.

So like this:

0001

0011

0111

etc ...

Is the coding called gray?

mathworld.wolfram.com/GrayCode.html

The feature of Gray code is that only one bit changes at a time. (But that's not important in your case as I imagine that the sensors all go to zero between pockets)

Anyway, unless you want to modify the carousel comp to use your unusual encoding, it probably makes sense to move the screw heads around.

Please Log in or Create an account to join the conversation.

- mgm

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 210

- Thank you received: 13

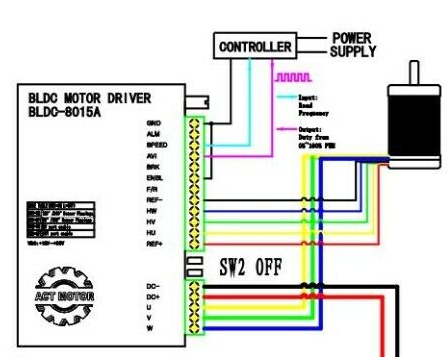

I have this driver with motor:

I can control the speed with the potentiometer on the driver, unfortunately the adjustment is very difficult with it. How can I control the speed with my 7i76e if I already use all 5 axes? A very small speed is enough for me since this is the motor for my Geneva wheel.

Keyword PWM, but with which pin could this go? maybe an analog output .....

or am I on the wrong track there?

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

You might be able to set a constant speed with the potentiometer and just enable / disable the drive frim LinuxCNC.

Please Log in or Create an account to join the conversation.

- mgm

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 210

- Thank you received: 13

The on and off I do with a relay on the enable.

I still have this description:

=15pxSpeed regulation choice(RV ; AVI)

1. Setup speed by potentiometer (RV).The dipswitch SW2 must be ON status to enable this function.

CW rotate the potentiometer will increase speed. CCW- speed down.

2. Setup speed by analog input (AVI). The dipswitch SW2 must be OFF status to enable this

function.。AVI terminal accept 0~5V voltage or PWM signal from controller。AVI terminal with input

resistance of 100K,current consumption≤5mA。

Reference table

S W 2 Command to

Speed adjust Comman Current

O N RV CW—speed up,CCW—speed down - -

O F F AVI 0~5V analog input 0~5V volage ≤5mA

O F F AVI PWM 1KHz duty cycle -

Only one of above two modes can be used to adjust speed (another mode shall be enabled).

Once AVI terminal applied, (RV) potentiometer shall be CCW turned to Min. position。PWM signal are 5V TTL leve

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- Preparation for the self-construction of a carousel changer