Mill atc configuration

- Artur_1617

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 157

- Thank you received: 5

Need to add pressure sensor, orient and homing Z with homing corousel.

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

I haven't seen many commercial ATCs, but the last one I looked at used a switch to detect the movement of the clamp mechanism rather than a pressure sensor, which makes sense to cover the case of a stuck mechanism.

My own tool clamping system is pneumatic (no tool changer, I didn't get that far, but the rapid tool changes are great) and that sometimes sticks if the spindle gets very hot. To detect tool release with that I would definitely be looking at piston motion rather than pressure (as it physically ejects the tool in the last part of the stroke).

However, if your system has an air purge to clean the taper (as many do) then detecting that pressure _dropping_ would be a good detection of tool release.

Please Log in or Create an account to join the conversation.

- Artur_1617

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 157

- Thank you received: 5

In finaly version of spindle well by atached sensor of finish motion stroke piston.

Now about orient.

Read all topic with orient but no found setup like mine. Try to mixed all in one but not lucky.

Think the first one orient atached in first post was the best for working with my setup.

I use relay for spindle cw on. # --- SPINDLE-CW --- net spindle-cw hm2_5i25.0.7i77.0.0.output-01

Can You write me example how turn on spindle orient with turn on spindle?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

I have compressor than make 8bar and drop to 6 before start to load again. Spindle need 6.3bar to unclamp cone.

What is the rated pressure of the compressor reservoir? You can generally adjust the pressure switch to cut in and out at higher pressures.

But, even then, I think that 8 bar is too close to the limit for reliability. Can you use a 10 bar compressor or a bigger cylinder?

I had this problem with my pneumatic drawbar, and re-made the actuator cylinder as a tandem one:

Read all topic with orient but no found setup like mine. Try to mixed all in one but not lucky.

Think the first one orient atached in first post was the best for working with my setup.

I use relay for spindle cw on. # --- SPINDLE-CW --- net spindle-cw hm2_5i25.0.7i77.0.0.output-01

Can You write me example how turn on spindle orient with turn on spindle?

Do you plan to orient with only clockwise motion? Is there a physical stop pin?

Please Log in or Create an account to join the conversation.

- Artur_1617

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 157

- Thank you received: 5

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

Dont see any problem orient with only clockwise motion. Dont have physical stop pin.

The problem is with inertia in the spindle.

If you turn on the spindle until is it in position, and then turn it off, by the time it stops it won't be in position.

Can you explain how you intend spindle orient to work? Is there a brake? Encoder? Index?

Generally the spindle motor is operated like a position-mode servo during orient, and for that it needs to be controlled with variable speed and in both directions.

If you are not going to do it like that, then I can't help with the HAL unless I know what you do expect.

Please Log in or Create an account to join the conversation.

- Artur_1617

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 157

- Thank you received: 5

The lower rpm spindle turn 30rpm if i stop them from this rpm stop very fast. Regenerative resistor for stop is there.

About directions, You now better if they need both directions, now i have cw and ccw physical pin for rigid tapping.

Please Log in or Create an account to join the conversation.

- Artur_1617

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 157

- Thank you received: 5

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

You can try using a wcomp component:

linuxcnc.org/docs/stable/html/man/man9/wcomp.9.html

It will take a little work to get the "max" and "min" values for it. max needs to be the position from the orient comp + one or two encoder counts, and min needs to be - one or two.

loadrt wcomp

loadrt sum2 count=2

setp sum2.0.in1 0.01

setp sum2.1.in1 -0.01

net o_angle orient.0.position sum2.0.in0 sum2.1.in0

net o_max sum2.0.out wcomp.0.max

net o_min sum2.1.out wcomp.0.min

net o_fwd wcomp.0.under => Use this pin to move the spindle FWD

net o_rev wcomp.0.over ==> and this onw for REVThis will need massaging to fit your system, and is untested.

Please Log in or Create an account to join the conversation.

- Artur_1617

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 157

- Thank you received: 5

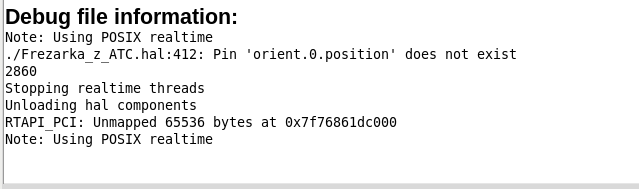

Attachments:

Please Log in or Create an account to join the conversation.