Mill atc configuration

- Artur_1617

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 5

20 Aug 2023 12:14 - 20 Aug 2023 12:21 #278541

by Artur_1617

Replied by Artur_1617 on topic Mill atc configuration

My encoder on spindle is ABZ with index output.

Add

net spindle-index-enable <=> orient-pid.index-enable

loadrt scale names=scale.spindle,scale.orient

addf scale.orient servo-thread

setp scale.orient.gain 58 #232/4 this is my setup from spindle

net spindle-vel-fb-rps => scale.orient.in

net orient-fb-rpm scale.orient.out

Can You write little more how connect this?

Add

net spindle-index-enable <=> orient-pid.index-enable

loadrt scale names=scale.spindle,scale.orient

addf scale.orient servo-thread

setp scale.orient.gain 58 #232/4 this is my setup from spindle

net spindle-vel-fb-rps => scale.orient.in

net orient-fb-rpm scale.orient.out

Can You write little more how connect this?

Attachments:

Last edit: 20 Aug 2023 12:21 by Artur_1617.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4626

- Thank you received: 2047

20 Aug 2023 12:40 - 20 Aug 2023 12:40 #278542

by Aciera

Replied by Aciera on topic Mill atc configuration

I would try like this:

1. Remove these lines:

setp scale.orient.gain 58

net spindle-vel-fb-rps => scale.orient.in

net orient-fb-rpm scale.orient.out => #abs.orient.in

2. Change these lines:

# Encoder position into orient component and orient pid

net spindle-revs => orient.position

net spindle-revs => orient-pid.feedback

to this:

setp scale.orient.gain 0.00277778

net spindle-revs => scale.orient.in

net spindle-revs-scaled <= scale.orient.out => orient.position => orient-pid.feedback

1. Remove these lines:

setp scale.orient.gain 58

net spindle-vel-fb-rps => scale.orient.in

net orient-fb-rpm scale.orient.out => #abs.orient.in

2. Change these lines:

# Encoder position into orient component and orient pid

net spindle-revs => orient.position

net spindle-revs => orient-pid.feedback

to this:

setp scale.orient.gain 0.00277778

net spindle-revs => scale.orient.in

net spindle-revs-scaled <= scale.orient.out => orient.position => orient-pid.feedback

Last edit: 20 Aug 2023 12:40 by Aciera.

The following user(s) said Thank You: Artur_1617

Please Log in or Create an account to join the conversation.

- Artur_1617

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 5

20 Aug 2023 13:20 #278544

by Artur_1617

Replied by Artur_1617 on topic Mill atc configuration

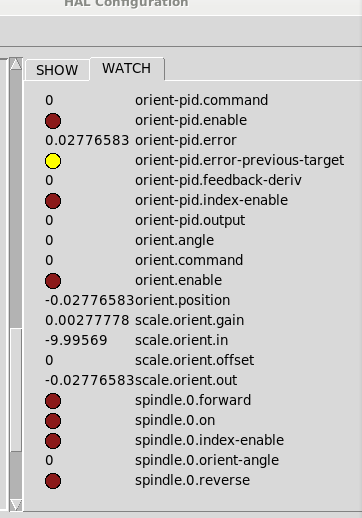

Not working.

screen8 is after turn 10times cw spindle with hand

screen9 is after start orient. And finish turn 10times cww for orient

screen8 is after turn 10times cw spindle with hand

screen9 is after start orient. And finish turn 10times cww for orient

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4626

- Thank you received: 2047

20 Aug 2023 13:35 #278545

by Aciera

Replied by Aciera on topic Mill atc configuration

If you look at 'orient-pid.feedback' and turn the spindle by hand, does is go from 0 to 1 in one revolution and then start at 0 again?

Please Log in or Create an account to join the conversation.

- Artur_1617

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 5

20 Aug 2023 13:58 - 20 Aug 2023 14:05 #278547

by Artur_1617

Replied by Artur_1617 on topic Mill atc configuration

orient-pid.feedback after one turn is 0,0027 and not set to zero it keeps growing.

I marked spindle shaft.

And if start linuxcnc with mark on position 0 this well be 0 for orient. I turn spindle to 90 and start linuxcnc this is new 0.

For now index is random not from index encoder input.

I marked spindle shaft.

And if start linuxcnc with mark on position 0 this well be 0 for orient. I turn spindle to 90 and start linuxcnc this is new 0.

For now index is random not from index encoder input.

Last edit: 20 Aug 2023 14:05 by Artur_1617.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4626

- Thank you received: 2047

20 Aug 2023 14:45 #278549

by Aciera

Replied by Aciera on topic Mill atc configuration

I see, so you will have to loadrt and addf a 'not' component (say 'not.spindle-index') and use the encoder input index to reset the encoder counter:

Like this:

net spindle-input-index <= hm2_5i25.0.encoder.04.input-index => not.spindle-index.in

net spindle-enc-reset <= not.spindle-index.out => hm2_5i25.0.encoder.04.reset

Like this:

net spindle-input-index <= hm2_5i25.0.encoder.04.input-index => not.spindle-index.in

net spindle-enc-reset <= not.spindle-index.out => hm2_5i25.0.encoder.04.reset

Please Log in or Create an account to join the conversation.

- Artur_1617

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 5

20 Aug 2023 15:58 - 20 Aug 2023 16:16 #278553

by Artur_1617

Replied by Artur_1617 on topic Mill atc configuration

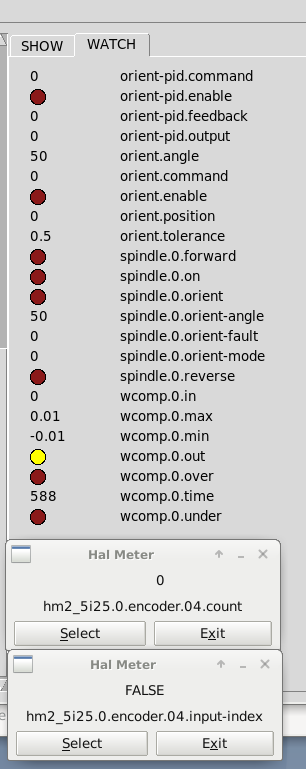

Maked the changes and;

If turn spindle cww encoder.04.count go from 0 to 232 then set to 0 and go again 0 to 232 and we have some orient-pid.feedback working

If turn spindle cw encoder.04.count not count nothing only when past index show 1 and back to 0. After this orient not start orient-pid.feedback is 0

When orient direction is close for run cww start orient and still turning becouse not count on encoder.04.count input

Encoder 04 is true out of index and is false when is on index is important?

Screen11 after turn spindle cw

Screen12 after turn spindle ccw

If turn spindle cww encoder.04.count go from 0 to 232 then set to 0 and go again 0 to 232 and we have some orient-pid.feedback working

If turn spindle cw encoder.04.count not count nothing only when past index show 1 and back to 0. After this orient not start orient-pid.feedback is 0

When orient direction is close for run cww start orient and still turning becouse not count on encoder.04.count input

Encoder 04 is true out of index and is false when is on index is important?

Screen11 after turn spindle cw

Screen12 after turn spindle ccw

Attachments:

Last edit: 20 Aug 2023 16:16 by Artur_1617.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4626

- Thank you received: 2047

20 Aug 2023 17:52 #278557

by Aciera

Replied by Aciera on topic Mill atc configuration

Sounds like your encoder scale is not correct, so you'll have to fix that first.If turn spindle cww encoder.04.count go from 0 to 232 then set to 0 and go again 0 to 232

Please Log in or Create an account to join the conversation.

- Artur_1617

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 5

20 Aug 2023 18:37 #278559

by Artur_1617

Replied by Artur_1617 on topic Mill atc configuration

Encoder is 58 imp per rev 58x4=232

But now see other things. When turn spindle with hand wery slow see encoder is couting onlt to 230 when On index. And start counting again when index is off. We loos two encoder count.

But now see other things. When turn spindle with hand wery slow see encoder is couting onlt to 230 when On index. And start counting again when index is off. We loos two encoder count.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4626

- Thank you received: 2047

20 Aug 2023 19:25 #278563

by Aciera

Replied by Aciera on topic Mill atc configuration

so i guess you could try changing this (1/360):

setp scale.orient.gain 0.00277778

to this (1/230):

setp scale.orient.gain 0.004347826

It's late now and I've run out of time for today. Good luck.

setp scale.orient.gain 0.00277778

to this (1/230):

setp scale.orient.gain 0.004347826

It's late now and I've run out of time for today. Good luck.

The following user(s) said Thank You: tommylight, Artur_1617

Please Log in or Create an account to join the conversation.

Time to create page: 0.187 seconds