- Hardware & Machines

- CNC Machines

- Milling Machines

- Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

- new2linux

- Offline

- Platinum Member

-

Less

More

- Posts: 711

- Thank you received: 9

17 Apr 2017 19:25 #91537

by new2linux

Replied by new2linux on topic Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

thanks andypugh,

Is there a target value for the I & D, or just trial and error? Will work that in tomorrow.

Many thanks!

Is there a target value for the I & D, or just trial and error? Will work that in tomorrow.

Many thanks!

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

17 Apr 2017 20:04 #91539

by Todd Zuercher

Replied by Todd Zuercher on topic Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

The target value is what ever works with your hardware, and configuration. There are too many variables to say x value should with work with y setup. That is why it is called "tuning" a servo. (it is a lot like tuning a musical instrument.)

The following user(s) said Thank You: new2linux

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

Less

More

- Posts: 711

- Thank you received: 9

17 Apr 2017 21:17 #91549

by new2linux

Replied by new2linux on topic Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

Many thanks!!

Just a small amount of I & D have made a big difference, the oscillation way down. I can see why its compared to instrument tuning. Now the linuxcnc computer is not by internet computer, there is the extra step involved now, to relay updates.

many thanks!!

Just a small amount of I & D have made a big difference, the oscillation way down. I can see why its compared to instrument tuning. Now the linuxcnc computer is not by internet computer, there is the extra step involved now, to relay updates.

many thanks!!

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

Less

More

- Posts: 711

- Thank you received: 9

18 Apr 2017 18:01 - 19 Apr 2017 18:42 #91593

by new2linux

Replied by new2linux on topic Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

Many thanks!!

The trace in hal scope, is there a specific shape, or say the beginning, the corners will or will not have a small spike up wards, just as it starts is acceptable or just tune it till the servo won"t over heat, and works well at most speeds. Trying to understand when to stop tuning.

thanks

The trace in hal scope, is there a specific shape, or say the beginning, the corners will or will not have a small spike up wards, just as it starts is acceptable or just tune it till the servo won"t over heat, and works well at most speeds. Trying to understand when to stop tuning.

thanks

Last edit: 19 Apr 2017 18:42 by new2linux. Reason: terms

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

18 Apr 2017 19:43 #91596

by Todd Zuercher

Replied by Todd Zuercher on topic Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

Generally you want to minimize the amount of following error. Usually within about 3-5 encoder counts is about as good as you can get. (You'll have to calculate what distance 1 encoder count equals.) You should strive for a system that is at least quiet at rest and not oscillating at a aplitude. If the drive is bouncing back and forth constantly, it can quickly overheat itself and or the motor. This is usually a sign of to much of something, P, I, D... To much of these or an FF term can all lead to over shoot and cause these oscillations. It is also possible that the velocity loop in the drive may need tuned better.

The following user(s) said Thank You: new2linux

Please Log in or Create an account to join the conversation.

- lakeweb

-

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 23

18 Apr 2017 19:52 #91597

by lakeweb

Replied by lakeweb on topic Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

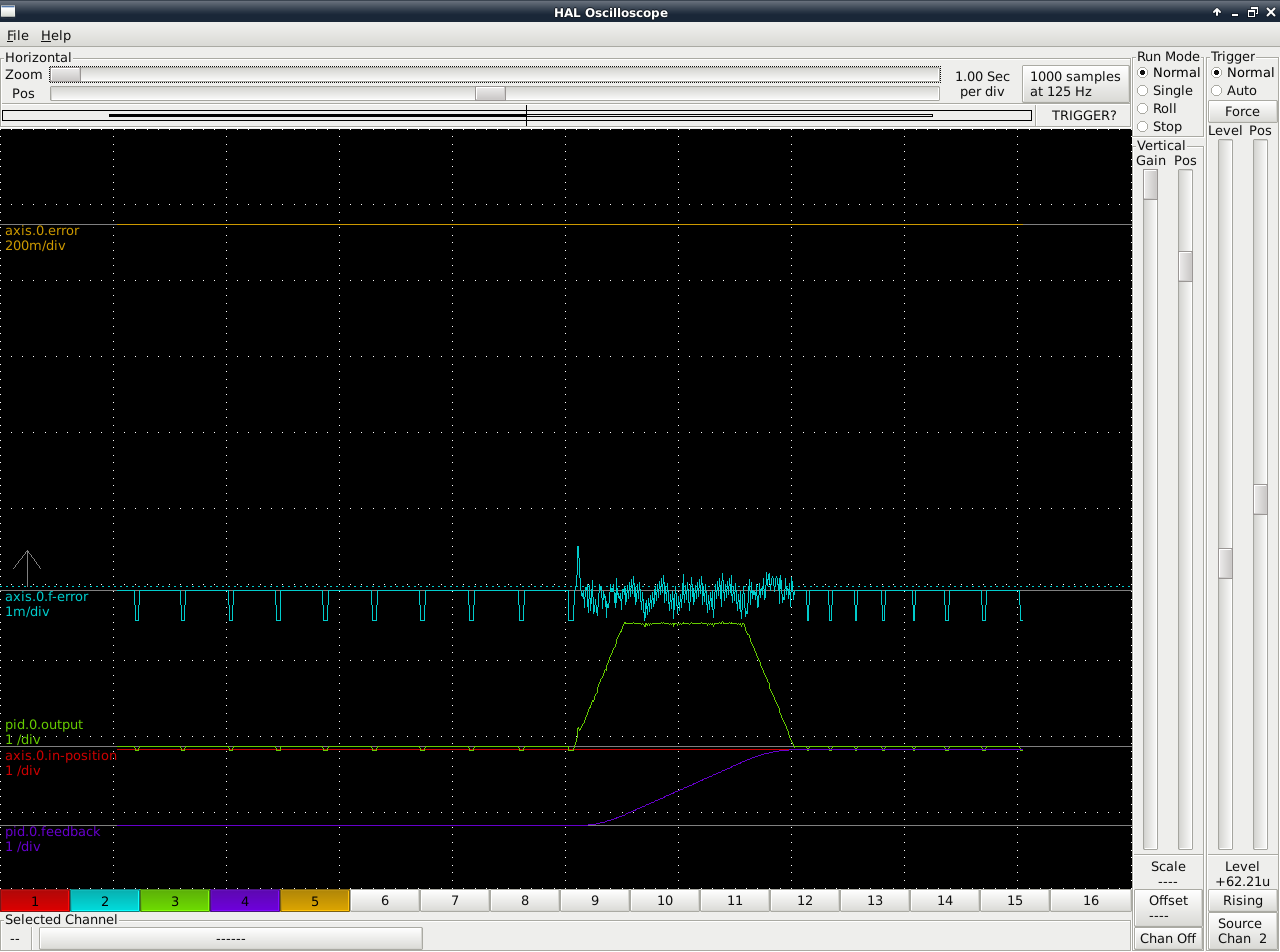

If you are using the likes of M1X1F5 in the command window, then you want to look at the hal trace axis.0.f.error. Note that the gain is set all the way up for this channel

from: Page Source

Best, Dan.

from: Page Source

Best, Dan.

The following user(s) said Thank You: new2linux

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

Less

More

- Posts: 711

- Thank you received: 9

19 Apr 2017 19:13 #91667

by new2linux

Replied by new2linux on topic Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

Generally you want to minimize the amount of following error. Usually within about 3-5 encoder counts is about as good as you can get. (You'll have to calculate what distance 1 encoder count equals.)

Todd Many thanks for your help! I see the DRO is as accurate as the ball screw pitch, it would appear. When you talk about "following error" is the (in my case a dip in the hal trace) amount it wants to over shoot the target? To calculate what 1 encoder count equals, I would 2000 count/quadrant(8000/rev); x .2 pitch of ball screw; 16 to 44 timing pulley ratio; and evaluate that way?

lakeweb, many thanks for your link to your project, looks great! Currently, my tuning has not enabled me to see (hal trace) screen like yours, but the 60"/min jog looks and sounds very very good, I started low several times and believe the settings are at the low end of what is ideal. No oscillating, noise or sluggishness, but not uniform with perfect symmetrical angled lines, mine goes (at 60"/min) high spike (not crazy) at beginning, almost level line (small amount of drop over long run) and drop (nearly vertical down) at end of run, with out going below starting datum. I tried to get screen shot but with no luck.

Many thanks!

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

19 Apr 2017 19:49 #91671

by Todd Zuercher

Replied by Todd Zuercher on topic Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

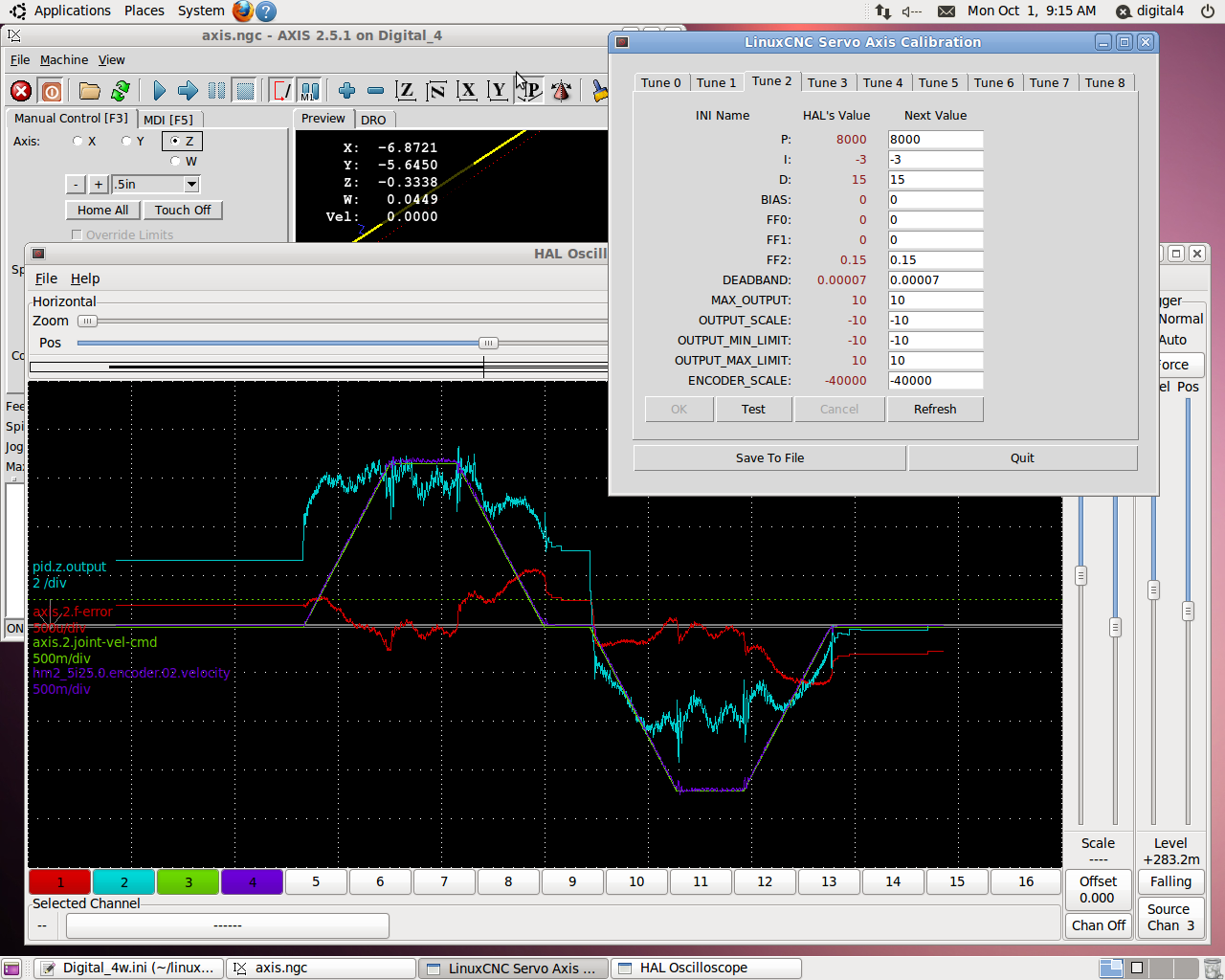

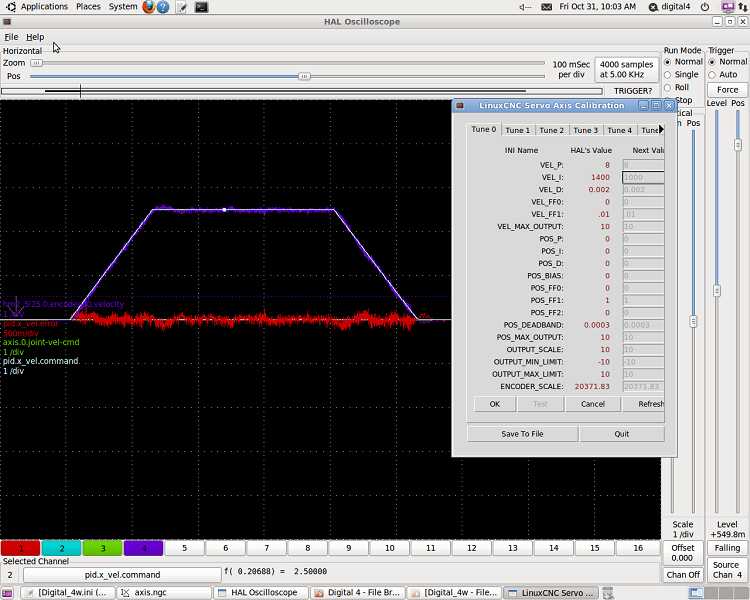

Like in the picture of halscope posted by lakeweb above, he has a small spike of error of about 0.0005 at the beginning of the movement.

The distance moved by one encoder count will simply be the inverse of your encoder scale for that axis. (1/x)

Don't get discouraged, it can take a while to learn the feel for how to tune a servo. Especially if the drives you are tuning are torque and not velocity input.

It took me a long time and a lot of fiddling to get from this first picture to the 2nd (this is on a torque mode servo)

The distance moved by one encoder count will simply be the inverse of your encoder scale for that axis. (1/x)

Don't get discouraged, it can take a while to learn the feel for how to tune a servo. Especially if the drives you are tuning are torque and not velocity input.

It took me a long time and a lot of fiddling to get from this first picture to the 2nd (this is on a torque mode servo)

The following user(s) said Thank You: new2linux

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

Less

More

- Posts: 711

- Thank you received: 9

20 Apr 2017 15:19 - 20 Apr 2017 15:23 #91693

by new2linux

Replied by new2linux on topic Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

Many thanks for the encouraging words!

So negative values are acceptable, (as in "I" in the 1st pic) as well? My system is set up as "torque mode" not velocity mode, so my hope is I can refine the tuning more w/o great difficulty, to get a hal trace similar to the one in bottom pic.

Thanks for all the great help!

So negative values are acceptable, (as in "I" in the 1st pic) as well? My system is set up as "torque mode" not velocity mode, so my hope is I can refine the tuning more w/o great difficulty, to get a hal trace similar to the one in bottom pic.

Thanks for all the great help!

Last edit: 20 Apr 2017 15:23 by new2linux. Reason: clearify

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17514

- Thank you received: 5118

20 Apr 2017 17:05 #91700

by PCW

Replied by PCW on topic Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

Negative I does not work safely with the PID component

(nor does it make any sense for a velocity or torque mode servo)

Velocity mode servos are tuned chiefly with P and FF1

Torque mode servo need mainly P,I,D and FF2

Torque mode servo tuning will benefit from running the servo loop faster than

LinuxCNCs default 1KHz and using a dual PID loop (position loop around a velocity loop)

(nor does it make any sense for a velocity or torque mode servo)

Velocity mode servos are tuned chiefly with P and FF1

Torque mode servo need mainly P,I,D and FF2

Torque mode servo tuning will benefit from running the servo loop faster than

LinuxCNCs default 1KHz and using a dual PID loop (position loop around a velocity loop)

The following user(s) said Thank You: new2linux

Please Log in or Create an account to join the conversation.

Moderators: piasdom

- Hardware & Machines

- CNC Machines

- Milling Machines

- Prototrak Plus Retrofit with Mesa 7i77 & 5i25 cards

Time to create page: 0.123 seconds